Dec . 10, 2024 09:39 Back to list

pvc pipe price per foot manufacturer

Understanding the Pricing of PVC Pipe Key Factors and Manufacturer Insights

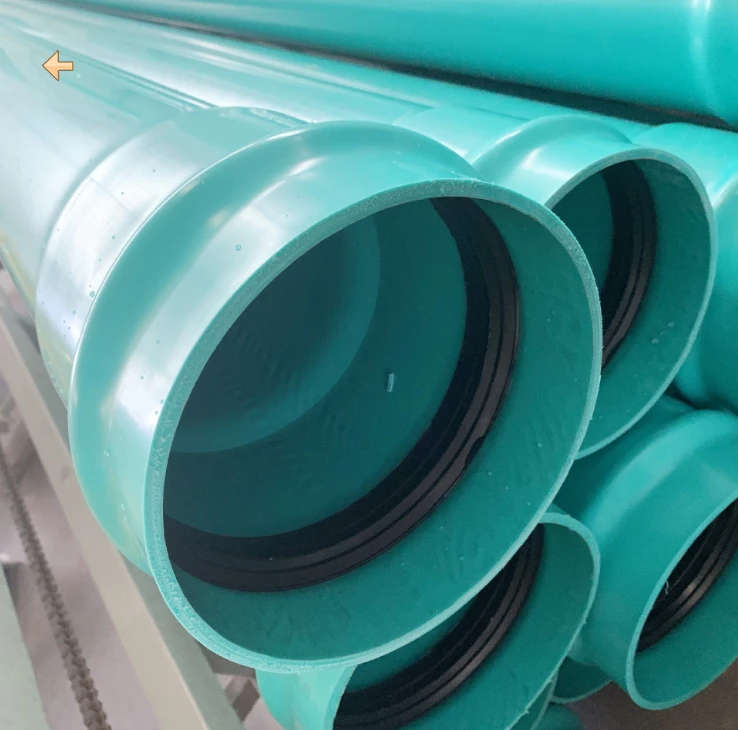

Polyvinyl chloride, commonly referred to as PVC, has become an essential material in various industries, particularly in construction, plumbing, and electrical applications. The demand for PVC pipes has soared due to their durability, cost-effectiveness, and versatility. However, understanding the pricing structure of PVC pipes, particularly the price per foot from manufacturers, is crucial for builders, contractors, and DIY enthusiasts alike. This article will explore the factors that influence PVC pipe prices and provide insights into the manufacturing process.

1. The Basics of PVC Pipe Pricing

When discussing PVC pipe pricing, it's important to note that the cost per foot can vary significantly based on several factors. Manufacturers typically provide a range of prices depending on the pipe's diameter, thickness, and intended application. On average, the price of PVC pipe can range from $0.50 to $6.00 per foot. However, prices may fluctuate based on market demand, raw materials costs, and geographic location.

2. Key Factors Influencing PVC Pipe Pricing

- Raw Material Costs The primary component of PVC pipe is the polyvinyl chloride resin, which is derived from petroleum-based products. Therefore, fluctuations in oil prices can have a direct impact on the cost of PVC pipes. Additionally, additives used to enhance the pipe's strength, flexibility, or UV resistance also affect pricing.

- Manufacturing Processes The cost of production plays a significant role in determining the final price of PVC pipes. Advanced manufacturing techniques, such as extrusion and injection molding, require significant investment in machinery and technology. Manufacturers that invest in more efficient technology can achieve economies of scale, thereby reducing costs and offering competitive pricing.

- Pipe Specifications PVC pipes come in various sizes and pressure ratings. Standard sizes, like 1-inch or 2-inch diameter pipes, generally cost less than larger or specialty pipes, such as those used in industrial applications or high-pressure scenarios. Furthermore, the wall thickness—indicative of the pipe's durability—also affects pricing.

pvc pipe price per foot manufacturer

- Market Competition The number of manufacturers and suppliers in a given region can influence pricing dynamics. In areas with multiple suppliers, competition often leads to lower prices. Conversely, in regions with limited options, prices may be higher due to reduced competition.

- Distribution Costs Transportation and shipping costs can also impact the final price of PVC pipes. Manufacturers located closer to end-users may have lower distribution costs, thus allowing them to offer more competitive pricing compared to those who need to ship products over long distances.

3. The Role of Quality and Certification

While price is a crucial consideration, it is equally important to consider the quality and certification of PVC pipes. Manufacturers adhering to industry standards, such as ASTM or ISO certifications, are likely to provide higher quality products, which can lead to better performance and longevity. Although these pipes might come with a higher price tag, the long-term benefits, such as reduced maintenance and replacement costs, can outweigh the initial investment.

4. Buying PVC Pipes from Manufacturers

When purchasing PVC pipes, it is advisable to engage directly with manufacturers or established suppliers. This approach allows buyers to gain insights into pricing, product specifications, and potential bulk discounts. Additionally, many manufacturers offer online calculators to estimate costs based on specific requirements, which can be immensely helpful for project budgeting.

5. Conclusion

In summary, the pricing of PVC pipes is determined by multiple factors, including raw material costs, manufacturing processes, pipe specifications, market competition, and distribution costs. While price per foot is a significant consideration for buyers, investing in quality products can lead to better outcomes in terms of durability and performance. As the demand for PVC piping continues to grow, staying informed about the pricing landscape and manufacturers’ offerings can aid in making optimal purchasing decisions. Whether you are a contractor, builder, or a DIY enthusiast, understanding these elements will help you navigate the complexities of PVC pipe procurement efficiently.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025