Dec . 21, 2024 18:15 Back to list

pvc pipe lengths factories

The Importance of PVC Pipe Lengths in Manufacturing A Closer Look

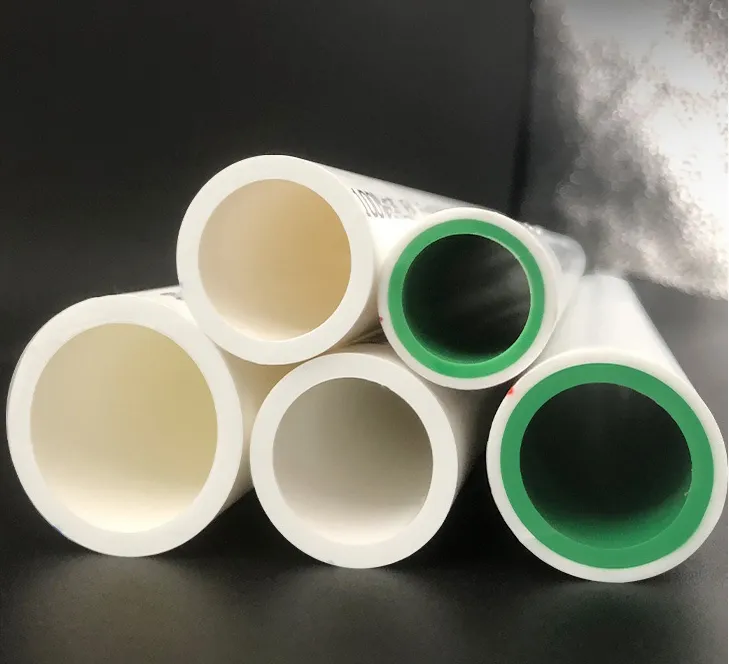

Polyvinyl chloride (PVC) pipes have become a staple in construction and plumbing industries due to their durability, cost-effectiveness, and resistance to a variety of chemicals. As factories around the world ramp up production to meet growing demand, understanding the implications of PVC pipe lengths on manufacturing processes is crucial. This article delves into the significance of PVC pipe lengths, the factors influencing their production, and the broader impact on various industries.

Understanding PVC Pipe Lengths

PVC pipes are produced in various lengths, typically ranging from 10 to 20 feet, depending on the intended application. The length of the pipe can significantly affect transportation, installation, and overall project costs. In certain contexts, shorter lengths might be easier to handle and transport, especially in urban areas with limited access. However, longer pipes can reduce the number of joints and fittings needed, which can enhance the integrity of the plumbing system and diminish the likelihood of leaks.

Impact of Pipe Length on Manufacturing

Pipe manufacturers often face challenges regarding the standardization of lengths. While certain industries might prefer specified lengths, other sectors, like irrigation or industrial applications, often require custom solutions. This variability demands flexibility from factories, which must ensure they can adapt to fluctuating market needs while maintaining efficient production processes.

Additionally, the machinery used in the manufacturing of PVC pipes must be calibrated to produce specific lengths accurately. For instance, extrusion machines, which shape molten PVC into pipes, need precise settings to ensure that the finished products meet industry standards. Regular maintenance and periodic updates to machinery can help factories keep up with demands for varied lengths.

Logistics and Distribution

The choice of PVC pipe lengths also influences the logistics of distribution. Longer pipes require specialized transportation methods, such as flatbed trucks, which can increase shipping costs. On the other hand, shorter lengths can be bundled together more efficiently, optimizing space during transport. Factories need to weigh these factors when determining production strategies to minimize costs and maximize profit margins.

pvc pipe lengths factories

In addition, storage facilities often face challenges related to length. Organizations need to ensure they have proper storage solutions for various pipe lengths, as this can significantly influence inventory management. An effective storage system leads to quicker access and delivery times, which can enhance customer satisfaction.

Environmental Considerations

As the world shifts towards sustainable practices, the impact of manufacturing processes, including PVC pipe production, cannot be overlooked. The extrusion process, while efficient, generates waste in the form of excess material and off-cuts. Factories are increasingly adopting practices to recycle these remnants into new products, which can help reduce the environmental footprint of the production process.

Moreover, considerations regarding the lifespan of PVC pipes must also be taken into account. Longer pipes tend to have fewer joints, which can lead to lower chances of failure. Manufacturers that prioritize producing longer, high-quality pipes can position themselves as leaders in sustainability within the industry.

Future Trends and Innovations

Looking forward, the PVC pipe manufacturing sector is ripe for innovation. The rising integration of technology in manufacturing processes could lead to the development of more precise, efficient methods for creating pipes of various lengths. Additionally, advancements in materials science may yield PVC variants that offer enhanced performance characteristics, including improved flexibility and resistance to environmental stressors.

Furthermore, the growing demand for smart plumbing solutions, including sensors and automation, indicates that the future of PVC pipe production will be intertwined with technological advancements. Factories that embrace these changes can enhance their competitiveness and meet the diverse needs of customers more effectively.

Conclusion

In conclusion, the lengths of PVC pipes produced in factories have a profound impact on various aspects of manufacturing, logistics, environmental sustainability, and future trends. As industries continue to expand and evolve, it is essential for manufacturers to adapt to these changes, ensuring they meet the demands of their customers while embracing innovation and sustainability. By focusing on the significance of PVC pipe lengths and the processes that surround them, factories can thrive in an increasingly competitive market.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025