Sep . 07, 2024 13:20 Back to list

High-Quality PVC Pipe Dimensions and Standards | Customized Solutions

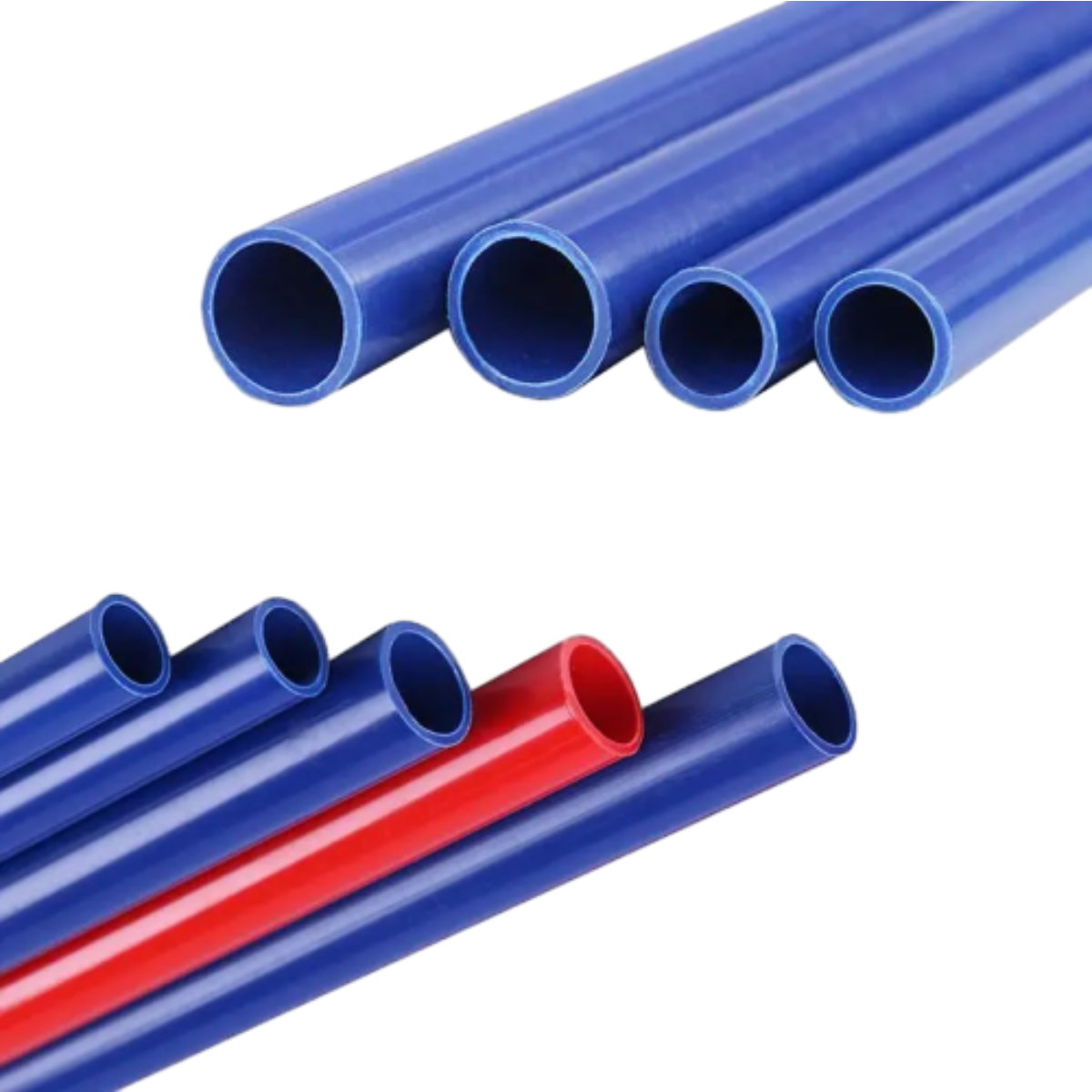

Understanding PVC Pipe Dimensions and Their Manufacturing

Polyvinyl chloride (PVC) pipes are essential components in various industries, including construction, plumbing, and electrical applications. Specifically, PVC pipes are favored for their durability, resistance to corrosion, and lightweight nature, making them an ideal choice for transporting water and other fluids. However, to effectively utilize PVC pipes, it is crucial to understand their dimensions and how these dimensions are standardized across different factories.

Standard Dimensions of PVC Pipes

PVC pipes come in various diameters and lengths, which are standardized to ensure compatibility and ease of installation. The most commonly used dimensions include schedules 40 and 80, which refer to the wall thickness of the pipe. Schedule 40 pipes have a thinner wall compared to schedule 80 pipes, allowing for lightweight construction but with less pressure capacity. These pipes typically range in diameter from ½ inch to 24 inches, catering to a wide variety of needs.

In addition to the diameter and wall thickness, the length of PVC pipes is usually standardized to 10 or 20 feet. Some manufacturers also produce longer lengths for specialized applications. Understanding these dimensions is essential when planning installations, as they directly affect flow rates and pressure ratings.

Importance of Accurate Dimensions

pvc pipe dimensions factories

Accurate dimensions in PVC pipes are crucial for several reasons. First, they ensure that the pipes fit properly with connectors, fittings, and other plumbing components. Mismatched dimensions can lead to leaks, reduced flow efficiency, and potential system failures. Secondly, the specifications must meet industry standards, such as those established by the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM). Compliance with these standards guarantees that the pipes can withstand specific conditions, such as temperature fluctuations and high pressure, ensuring durability and safety.

Manufacturing Processes of PVC Pipes

PVC pipe manufacturing involves several stages. Initially, raw PVC resin is mixed with additives to enhance its properties. This mixture is then subjected to heat and pressure, creating a molten material that can be extruded into the desired pipe shape. Once extruded, the pipes are cooled and cut to standard lengths. Quality control is an integral part of the manufacturing process, which ensures that each batch of pipes meets the specified dimensions and standards.

Factories that produce PVC pipes utilize advanced technologies to create precise dimensions. High-speed extrusion machines and computerized measurement systems allow manufacturers to maintain tight tolerances. Additionally, many factories conduct rigorous testing on their products, including pressure testing and dimensional accuracy checks, to ensure reliability and customer satisfaction.

Conclusion

Understanding PVC pipe dimensions is vital for effective application and installation in various projects. The standard sizes and manufacturing processes play a significant role in ensuring that these pipes serve their intended functions efficiently. As industries continue to evolve, the demand for high-quality PVC pipes with accurate dimensions will undoubtedly grow, driving innovations in manufacturing techniques and materials. Whether for plumbing, irrigation, or industrial applications, PVC pipes are a staple worldwide, and their dimensions are fundamental to their success.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025