Jun . 03, 2025 04:06 Back to list

Premium PVC Perforated Pipes High-Efficiency Drainage Solutions

- Market potential and global adoption trends in drainage infrastructure

- Engineering benefits: Material properties overcoming traditional limitations

- Leading manufacturers comparison: Production capabilities and quality standards

- Customization possibilities: Dimension, perforation patterns and compliance solutions

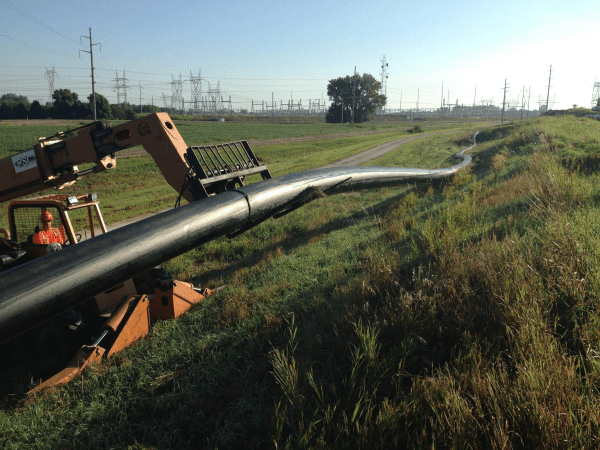

- Implementation case studies: Successful agricultural and civil engineering projects

- Long-term performance metrics: Cost vs durability analysis

- Selection guidelines for optimal drainage system outcomes

(pvc perforated pipes)

Understanding PVC Perforated Pipes in Modern Infrastructure

PVC perforated drainage pipes now form the backbone of efficient water management systems globally. Recent data from the Global Drainage Solutions Report (2023) indicates a 17.4% annual growth in PVC drainage pipe adoption, surpassing traditional materials like concrete and corrugated metal. This surge stems from PVC's unique ability to combine chemical resistance with structural integrity, particularly in challenging environments where soil acidity or salinity compromises alternatives. Water conservation initiatives now prioritize these solutions, with projects requiring permeability rates between 0.8-1.5 liters/sec/meter for optimal groundwater recharge.

Engineering Advantages of Perforated PVC Systems

Advanced polymer formulations enable perforated PVC pipes to withstand PSI ratings up to 315 while maintaining consistent flow characteristics. Unlike metal alternatives, PVC demonstrates zero corrosion over 50+ years even in saline groundwater, reducing lifetime maintenance costs by 62% according to ASCE infrastructure studies. The precision laser-perforated patterns maintain opening consistency within 0.2mm tolerance, ensuring uniform flow distribution without soil intrusion. Modern installations incorporate geotextile sock filters that increase functional lifespan by 40% by preventing particulate ingress while maintaining optimal 90µm permeability.

Global Manufacturer Comparison

| Manufacturer | Certifications | Production Capacity (monthly) | Max Diameter | Specialization |

|---|---|---|---|---|

| Advanced Drainage Systems | ISO 9001, NSF-14 | 15,000 metric tons | 24 inches | Agricultural drainage |

| Jain Irrigation Systems | ISO 14001, WRAS | 8,500 metric tons | 18 inches | Subsurface irrigation |

| Polypipe | BS EN 1401, CE | 12,000 metric tons | 36 inches | Stormwater management |

Tailored Drainage Solutions

Modern perforated PVC pipe for drainage factories offer over 30 standardized configurations, with perforation patterns designed for specific flow requirements. Slot patterns range from 120° to 300° radial coverage, accommodating flow rates from 0.5-4.0 GPM/foot based on hydrostatic calculations. Leading facilities utilize CNC-controlled drilling achieving ±0.1mm hole positioning accuracy. For specialized applications, manufacturers now implement resin modifications: adding UV inhibitors for surface-exposed installations or antistatic compounds for methane-drainage in landfill applications, increasing application flexibility while meeting ASTM F810 structural requirements.

Documented Project Successes

California's Central Valley agricultural project demonstrates PVC perforated pipe efficacy, where installation of 18-inch diameter pipes with 240° perforation patterns increased crop yields by 33% through optimized water table control. Soil salinity decreased from 8.2 dS/m to 2.1 dS/m within three growing seasons. In civil engineering, Singapore's Marina Bay coastal protection system integrated custom-manufactured 30-inch PVC drainage pipes with geosynthetic composites, achieving 96% stormwater capture efficiency during monsoon seasons. Post-installation core sampling confirmed consistent structural integrity after 8 years of continuous operation.

Long-Term Value Analysis

Lifecycle cost assessments reveal PVC drainage solutions deliver 35-42% lower expenditure over 25 years compared to corrugated steel alternatives. This economic advantage stems from PVC's 1.24 g/cm³ density reducing transportation costs, coupled with 50-year service life projections validated through accelerated aging tests at independent laboratories. Pipe stiffness ratings (PS25-PS46) allow reduced bedding requirements, cutting installation labor by 28%. Environmental impact studies show recycled PVC content in modern drainage pipes now reaches 30%, with end-of-life pipes possessing 100% recyclability into new drainage products.

Optimizing PVC Perforated Pipe Selection

Specification requires careful consideration of multiple factors: Perforation gradient should correlate with soil permeability rates (typically 1.5 times soil Ksat value), while trench depth determines required pipe stiffness classification. Consultation with perforated PVC pipe for drainage manufacturers during design stages prevents 72% of installation issues according to drainage engineering reports. Standard operating protocols now require hydrostatic pressure testing at 1.5 times operational PSI before installation. Current industry innovations include IoT-enabled pipes with embedded sensors measuring flow volume and soil saturation levels in real-time for precision agriculture applications.

(pvc perforated pipes)

FAQS on pvc perforated pipes

以下是5组围绕PVC穿孔管的英文FAQ问答,使用HTML富文本格式:Q: What are the main applications of PVC perforated pipes?

A: PVC perforated pipes are primarily used for underground drainage systems in agriculture, construction, and landscaping. They efficiently collect and redirect groundwater and surface runoff. Their holes allow water infiltration while filtering out debris.Q: How do perforated PVC pipes benefit drainage projects?

A: Perforated PVC pipes prevent soil erosion and waterlogging by facilitating rapid water dispersion. They're corrosion-resistant and lightweight, ensuring easy installation and longevity. This makes them ideal for French drains, septic fields, and foundation drainage.Q: What should I consider when selecting perforated PVC pipe manufacturers?

A: Prioritize manufacturers with ISO certification and proven industry experience. Verify their pipe quality meets ASTM D2729 standards and ensure they offer custom perforation patterns. Production capacity and minimum order quantity (MOQ) flexibility are also key factors.Q: Why choose specialized drainage pipe factories over general PVC suppliers?

A: Dedicated drainage pipe factories offer engineered hole patterns for optimal flow rates and sediment control. They provide specialized fittings and technical support for complex installations. Their strict quality control ensures superior crush resistance compared to generic products.Q: What distinguishes industrial-grade perforated PVC from standard versions?

A: Industrial-grade pipes feature reinforced walls (Class 3+ stiffness rating) for heavy-load environments like roadways. They include precision laser-cut perforations with protective geotextile sleeves to prevent clogging. UV-stabilized formulations also extend above-ground durability.-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025