Nov . 07, 2024 15:03 Back to list

Efficient Connection Solutions with PPR Quick Connector Manufacturing Techniques

The PPR Quick Connector Factory A Revolution in Plumbing Solutions

In the ever-evolving world of plumbing solutions, the PPR (Polypropylene Random Copolymer) quick connector has emerged as a game-changer. The PPR quick connector factory serves as a beacon of innovation, catering to the increasing demand for reliable, efficient, and environmentally friendly plumbing systems. This article delves into the significance of PPR quick connectors, the manufacturing processes involved, and their applications in modern plumbing systems.

Understanding PPR Quick Connectors

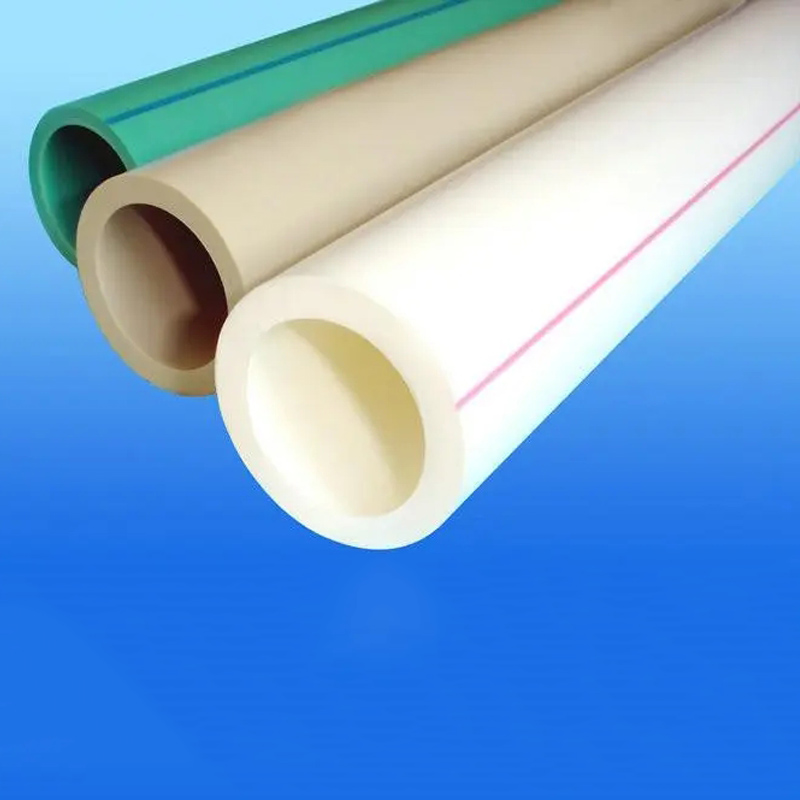

PPR quick connectors are fittings made from high-quality polypropylene materials designed to enable fast and easy connections in plumbing systems. These connectors are characterized by their user-friendly design, which allows for swift installation without the need for special tools or soldering. The plumbing industry has recognized PPR quick connectors for their durability, resistance to corrosion, and ability to withstand high temperatures and pressures, making them suitable for various applications.

Advantages of PPR Quick Connectors

One of the primary benefits of using PPR quick connectors is their ease of installation. Traditional plumbing methods often require complex tools and extensive labor, leading to increased costs and time. In contrast, PPR quick connectors simplify the installation process, allowing contractors and DIY enthusiasts alike to complete projects in a fraction of the time. This efficiency not only reduces labor costs but also minimizes the potential for human error during installation.

Moreover, PPR materials are known for their resistance to chemicals and scale build-up, which enhances the longevity of plumbing systems. Unlike traditional metal pipes, PPR does not corrode, ensuring that the water supply remains clean and safe for consumption. This makes PPR quick connectors an ideal choice for residential, commercial, and industrial piping systems alike.

The Manufacturing Process

ppr quick connector factory

The PPR quick connector factory is equipped with advanced technology to produce high-quality fittings that meet international standards. The manufacturing process begins with the selection of high-grade polypropylene material, sourced from reliable suppliers. This raw material undergoes a rigorous quality control process to ensure that it meets the necessary specifications for durability and safety.

Once the material is approved, it is fed into injection molding machines, where the actual manufacturing takes place. The machines heat the polypropylene until it reaches a molten state and then inject it into molds that shape the connectors. After cooling, the connectors are removed from the molds and subjected to further inspection to ensure uniformity and quality.

Quality assurance is a critical aspect of the manufacturing process. Each batch of PPR quick connectors undergoes stringent testing for pressure tolerance, temperature resistance, and overall integrity. This commitment to quality guarantees that the final products can withstand the rigors of daily use in various plumbing applications.

Applications of PPR Quick Connectors

PPR quick connectors are versatile and can be used in numerous applications, including hot and cold water supply systems, heating systems, irrigation, and industrial plumbing. Their lightweight nature makes them easy to transport and install, while their resistance to thermal expansion ensures they maintain their integrity even in fluctuating temperatures.

In residential plumbing, PPR quick connectors simplify the installation of piping systems, allowing homeowners to upgrade their plumbing with minimal disruption. In commercial settings, these connectors facilitate quick repairs and modifications, reducing downtime and maintaining operational efficiency.

Conclusion

The PPR quick connector factory epitomizes innovation in plumbing solutions, offering products that combine efficiency, durability, and ease of use. As the demand for reliable plumbing systems continues to grow, PPR quick connectors stand out as a preferred choice for both professionals and DIY enthusiasts. By understanding the advantages and manufacturing processes of these connectors, stakeholders can make informed decisions that enhance the quality and reliability of plumbing installations. Whether for residential or commercial use, PPR quick connectors are set to transform the landscape of modern plumbing for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025