Dec . 03, 2024 18:38 Back to list

PPR Piping Solutions from Leading Manufacturing Facility for Reliable Plumbing Systems

Understanding PPR Piping Systems and Their Advantages

In the realm of plumbing and piping solutions, PPR (Polypropylene Random Copolymer) piping systems have emerged as a popular choice for both residential and industrial applications. Renowned for their durability, versatility, and superior performance, PPR pipes and fittings are manufactured through advanced processes in dedicated factories, ensuring high-quality standards that meet the demands of various applications.

What is PPR Piping?

PPR pipes are made from a type of thermoplastic polymer, which offers a series of advantages over traditional materials like PVC, copper, or galvanized steel. The random copolymerization technique used in the production of PPR results in a material that is lightweight, non-toxic, and resistant to corrosion and scaling. These properties make PPR piping systems ideal for carrying hot and cold water, as well as for heating systems.

Key Advantages of PPR Piping Systems

1. Durability and Longevity One of the standout features of PPR pipes is their exceptional durability. They can withstand extreme temperatures and pressures, making them a suitable option for a wide range of applications. PPR piping systems can last for over 50 years under proper conditions, significantly reducing the need for frequent replacements.

2. Corrosion Resistance Unlike metal pipes, PPR pipes do not rust or corrode over time, which ensures a clean and safe water supply. This corrosion resistance is particularly beneficial in environments prone to moisture and chemical exposure, contributing to the overall longevity and reliability of the piping system.

3. Energy Efficiency PPR pipes have excellent thermal insulation properties, which help to retain the temperature of the fluids transported within them. This feature contributes to energy efficiency by minimizing heat loss in hot water systems, which can lead to lower energy bills and a reduced carbon footprint.

4. Ease of Installation PPR pipes are lightweight and easy to handle, making installation straightforward. They can be connected through a fusion welding process, which creates a strong, leak-proof joint. This method not only simplifies installation but also ensures that the system is robust and reliable.

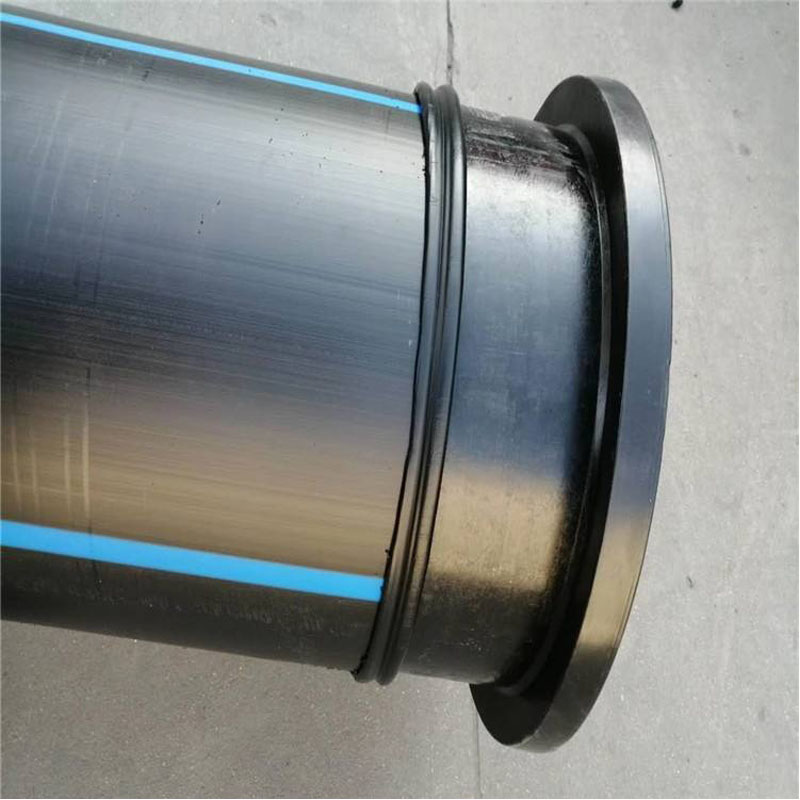

ppr piping system factory

5. Non-Toxic and Environmentally Friendly PPR piping is made from non-toxic materials, making it safe for the transport of potable water. Additionally, PPR is 100% recyclable, aligning with sustainable building practices and minimizing environmental impact.

6. Cost-Effectiveness Although the initial investment may be slightly higher than traditional piping materials, the long-term savings in maintenance and energy consumption make PPR piping systems a cost-effective solution. The durability and reduced installation time contribute to overall cost savings.

Manufacturing Process in PPR Piping Factories

To ensure the production of high-quality PPR pipes, manufacturers implement stringent quality control measures throughout the production process. The factories utilize advanced machinery for the extrusion of PPR materials, followed by rigorous testing to guarantee that the products meet international standards and certifications.

The manufacturing process includes

- Material Selection The raw materials used in PPR manufacturing are carefully selected to ensure optimal performance and longevity. - Extrusion The selected PPR granules are melted and extruded into pipes of various diameters. - Quality Inspection The pipes undergo rigorous testing for pressure resistance, thermal stability, and dimensional accuracy. - Final Assembly Fittings and additional components are made to ensure compatibility and convenience in installation.

Conclusion

PPR piping systems have established themselves as a reliable and efficient solution for various plumbing needs. With their unique properties, they are well-suited for modern construction requirements, offering advantages that traditional piping materials cannot match. Factories dedicated to the production of PPR pipes play a crucial role in ensuring that these systems meet the high standards expected in today's market. As more industries and homeowners recognize the benefits of PPR piping, its adoption is set to continue growing, paving the way for a more sustainable and efficient future in plumbing and piping solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025