Dec . 05, 2024 04:44 Back to list

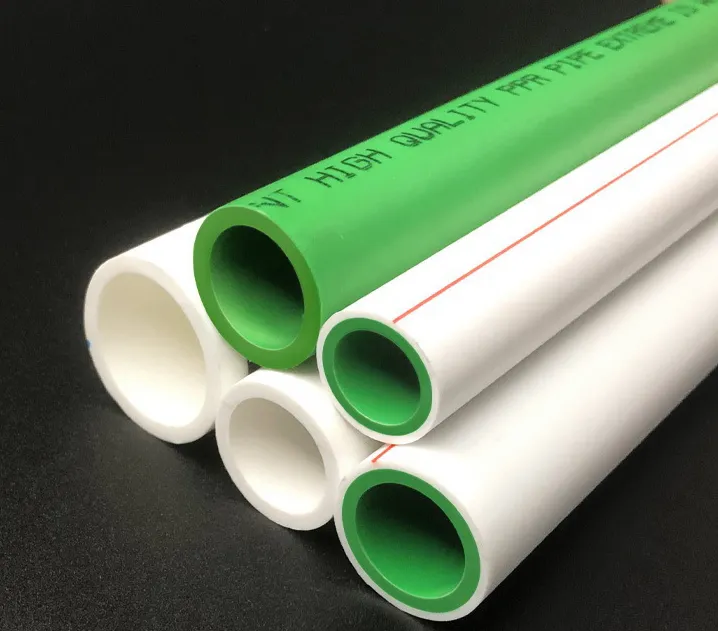

PPR Pipe Supplier Manufacturing Plants for Reliable Plumbing Solutions

Understanding PPR Pipe Suppliers and Factories

Polypropylene Random Copolymer (PPR) pipes have become a popular choice in the plumbing and construction industry due to their excellent durability, resistance to corrosion, and overall efficiency. As the demand for high-quality piping solutions continues to rise, understanding the role of PPR pipe suppliers and factories is crucial for manufacturers, contractors, and consumers alike.

What is PPR?

PPR is a type of thermoplastic used for making pipes and fittings, often employed in hot and cold water systems, as well as in industrial applications. Featuring a low thermal conductivity and outstanding chemical resistance, PPR pipes are suitable for a range of applications, including drinking water supply, irrigation systems, and heating installations.

The Role of PPR Pipe Suppliers

PPR pipe suppliers act as intermediaries between manufacturers and end-users, providing a comprehensive array of products that include pipes, fittings, and installation accessories. Suppliers play a vital role in ensuring that high-quality materials are available in the market, maintaining standards that comply with local and international regulations.

1. Quality Assurance

Reputable suppliers often work closely with factories to ensure quality control throughout the production process. They conduct rigorous testing of materials and finished products to guarantee they meet necessary standards, such as ISO, ASTM, and others. This commitment to quality safeguards the interests of consumers and encourages long-term relationships with contractors.

2. Variety of Products

A reliable PPR pipe supplier offers a diverse range of products to meet various needs. From different sizes and pressure ratings to assorted fittings and accessories, suppliers can cater to specific project requirements. This variety allows contractors to source all necessary materials from one location, optimizing both time and costs in the procurement process.

Experienced suppliers often bring a wealth of knowledge to the table. They can assist contractors in selecting the right materials for a particular project, providing recommendations on product specifications, installation techniques, and maintenance. This guidance is invaluable, especially for those who may be new to using PPR systems.

ppr pipe supplier factories

PPR Pipe Factories

PPR pipe factories are the backbone of the supply chain, responsible for the production of PPR pipes and fittings. These facilities employ specific technologies and methodologies to ensure that the products manufactured meet quality and safety standards.

1. Manufacturing Process

The production of PPR pipes involves several steps, including compounding, extrusion, and cooling. The raw materials, which include polypropylene resin and other additives, are compounded to enhance their performance characteristics. After that, they are extruded into the desired shapes and cooled down to maintain structural integrity.

2. Automation and Technology

Modern PPR pipe factories utilize advanced technology and automation to increase efficiency and reduce production costs. Automated systems allow for precise control over the manufacturing process, ensuring consistency in product quality. Furthermore, these factories often invest in environmentally-friendly practices, minimizing waste and energy consumption.

3. Compliance and Certification

Factories producing PPR pipes must comply with various regulations to ensure product safety and reliability. Certifications from local and international regulatory bodies demonstrate that these factories adhere to strict quality management systems, which boosts the credibility of suppliers that source their products from them.

The Future of PPR Pipe Supply

As construction methods evolve, and eco-friendly building solutions become more crucial, the demand for PPR pipes is likely to increase. Suppliers and manufacturers must be proactive in adapting to new market trends, such as sustainability and energy efficiency. Investing in research and development of innovative, higher-quality PPR products will be essential to remain competitive in the industry.

In conclusion, the significance of PPR pipe suppliers and factories cannot be overstated. They play a critical role in delivering quality products that meet the diverse needs of the plumbing and construction sectors. As the industry continues to grow, collaboration between suppliers and manufacturers will be key to driving innovation and ensuring the availability of high-performance PPR piping solutions in the market.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025