Nov . 01, 2024 21:38 Back to list

ppr pipes products

Understanding PPR Pipes and Their Products

PPR, or Polypropylene Random Copolymer, pipes have gained significant popularity in modern plumbing and piping applications. Known for their durability, versatility, and ease of installation, PPR pipes are an excellent choice for both residential and industrial projects. This article will explore the characteristics, advantages, applications, and products associated with PPR pipes.

PPR pipes are produced from a type of polypropylene resin that exhibits enhanced thermal and chemical resistance. This material allows PPR pipes to withstand high temperatures, making them suitable for hot and cold water applications. Additionally, their resistance to corrosion and scaling means they have a longer lifespan compared to traditional materials like metal or PVC pipes. PPR piping systems can typically handle temperatures up to 95°C (203°F) and the joints can be seamlessly welded, ensuring a leak-proof installation.

Understanding PPR Pipes and Their Products

In terms of environmental impact, PPR pipes are considered eco-friendly. They are 100% recyclable, and their production process results in lower greenhouse gas emissions compared to other piping materials. Consequently, selecting PPR pipes aligns with global efforts towards sustainable construction practices.

ppr pipes products

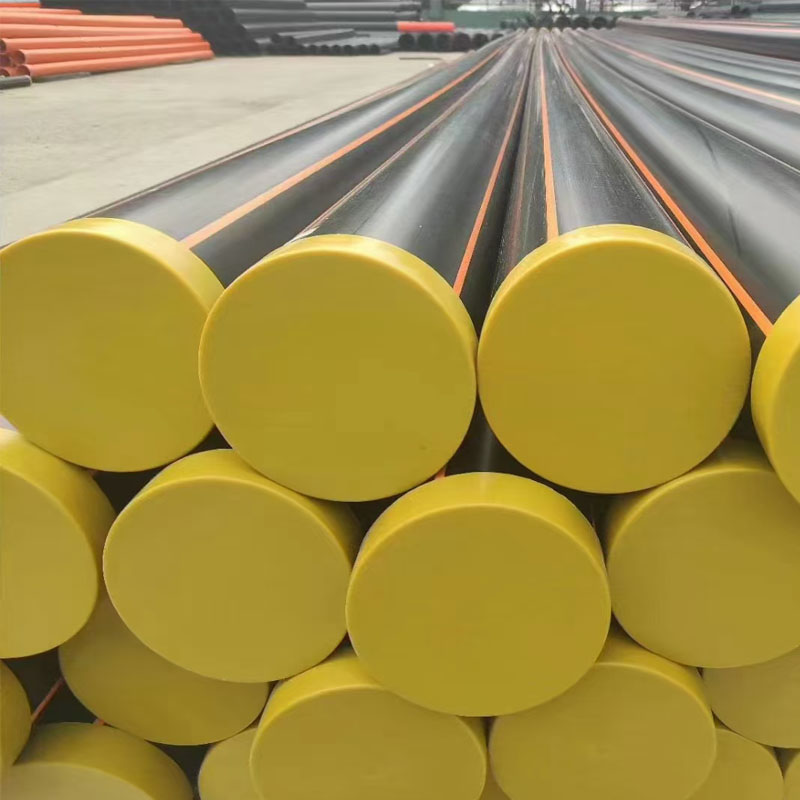

PPR products encompass a wide range of solutions for various applications. The most common products include pipes, fittings, valves, and accessories. PPR pipes are available in different diameters and pressure ratings, catering to diverse needs from small residential systems to large industrial installations. Fittings such as elbows, tees, and reducers enable the creation of complex plumbing layouts while maintaining a consistent flow and pressure.

The versatility of PPR products extends beyond plumbing; they are also used in heating systems, including underfloor heating and radiator connections. PPR has excellent thermal insulation properties, which help maintain the temperature of the fluids being transported, further enhancing energy efficiency in heating applications.

In the industrial sector, PPR pipes are employed in chemical processing, water treatment, and other applications where corrosion-resistant materials are essential. Their ability to handle aggressive chemicals without degrading makes them ideal for these demanding environments.

Installation of PPR piping systems requires specific tools and techniques, typically involving fusion welding. This process creates strong, permanent joints that are resistant to leaks and pressure changes. Although initial costs may be higher than other materials, the long-term savings derived from their durability, low maintenance needs, and energy efficiency make PPR pipes a wise investment.

In conclusion, PPR pipes and their related products represent a significant advancement in piping technology. Their durability, efficiency, and eco-friendliness position them as a preferred choice in various applications, from residential plumbing to complex industrial systems. As the demand for modern, efficient, and sustainable materials continues to rise, PPR pipes will undoubtedly play a pivotal role in the future of plumbing and piping solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025