Oct . 18, 2024 11:39 Back to list

Heating Time Considerations for PPR Pipe Production in Manufacturing Facilities

Efficient Heating Solutions for PPR Pipe Manufacturing

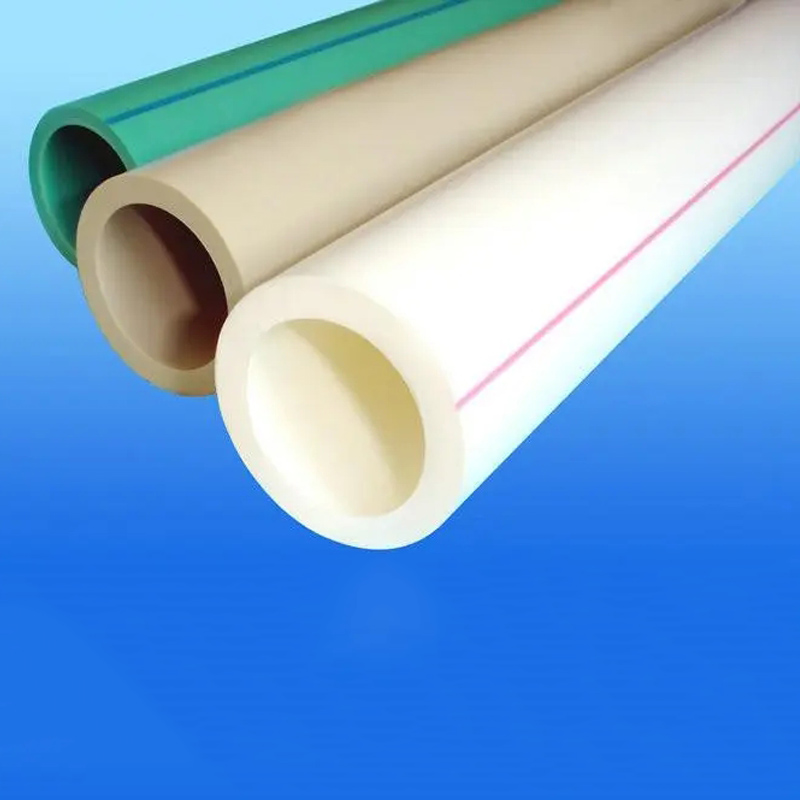

In the realm of plastic pipe manufacturing, the significance of efficient heating processes cannot be overstated, particularly when it comes to Polypropylene Random Copolymer (PPR) pipes. The demand for PPR pipes in various applications, including plumbing, heating systems, and irrigation, has surged due to their durability, corrosion resistance, and excellent thermal properties. As factories scale their production to meet this demand, optimizing the heating time for PPR pipes becomes a critical factor in enhancing overall production efficiency, reducing waste, and ensuring product quality.

Understanding PPR Pipe Heating

PPR pipes are known for their jointing capabilities that utilize a heat fusion technique, which involves melting the material at the jointing area before connecting two pipe segments together. This process requires precise heating to ensure that the joint achieves a stable bond while maintaining the integrity of the surrounding material. The effectiveness of this heating process is directly linked to several factors including the type of heating technology employed, the thickness of the pipes, and the ambient environmental conditions within the factory.

Key Heating Technologies

Several heating technologies are commonly employed in the manufacturing of PPR pipes. Among them, electric heating and infrared heating stand out as the most prevalent.

1. Electric Heating This conventional method utilizes electrical energy to generate heat in order to warm the pipe surfaces. It is fairly straightforward and provides excellent control over temperature, allowing for uniform heating of the entire circumference of the pipe. However, one downside is that it may consume significant amounts of energy, leading to higher operational costs.

2. Infrared Heating This method uses infrared radiation to elevate the temperature of the PPR pipes. Infrared heaters can significantly reduce heating times compared to traditional methods, as they deliver heat directly to the materials rather than warming the air around them. This efficiency can be particularly beneficial in high-volume manufacturing scenarios, allowing factories to improve their throughput without compromising on thermal quality.

Factors Affecting Heating Time

Heating time is influenced by various intrinsic and extrinsic factors. The thickness of the pipe is a crucial element, as thicker pipes require longer durations to reach the desired temperature. Additionally, the starting temperature of the pipes and the ambient temperature in the factory can affect how quickly the material heats up.

ppr pipe heating time factories

Another essential factor is the quality of the heating equipment. PPR pipe manufacturers should invest in high-quality machines designed with modern technologies that facilitate rapid and uniform heating. Furthermore, regular maintenance of heating equipment is vital for optimal performance. Over time, dust and residues can accumulate on heating elements, leading to inefficiencies and uneven heating.

Strategies for Optimization

To maximize efficiency and reduce heating time in PPR pipe production, manufacturers can adopt several strategies

1. Implementing Advanced Technology Investing in state-of-the-art heating equipment, such as high-speed infrared heaters or induction heating systems, can significantly enhance heating efficiency, reducing both time and energy consumption.

2. Automation and Control Systems Integrating automated control systems can help monitor and adjust the heating process in real-time, optimizing the energy usage and ensuring consistent results across production batches.

3. Training Personnel Ensuring that factory employees are well-trained in proper heating techniques can minimize mistakes and reduce time lost due to inefficient practices.

4. Regular Maintenance Establishing a routine maintenance schedule for heating equipment ensures that machines operate at peak performance, reducing downtime and extending their lifespan.

Conclusion

As the demand for PPR pipes continues to grow across various sectors, the importance of efficient heating processes in manufacturing cannot be underestimated. By exploring innovative heating technologies, optimizing processes, and ensuring proper maintenance, factories can significantly reduce heating times, improve product quality, and decrease operational costs. The future of PPR pipe production appears promising, as advancements in heating technology continue to pave the way for greater efficiency and sustainability within the industry. With a concerted effort towards these improvement strategies, manufacturers can stay ahead of the curve in a competitive market, delivering high-quality products that meet the ever-increasing consumer demands.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025