Dec . 10, 2024 07:38 Back to list

ppr pipe coupling manufacturer

Understanding PPR Pipe and Coupling Manufacturers A Comprehensive Overview

In the world of plumbing and piping systems, PPR (Polypropylene Random Copolymer) pipes have gained immense popularity due to their durability, chemical resistance, and ease of installation. As a result, the demand for high-quality PPR pipe coupling manufacturers has also surged. This article delves into the key aspects of PPR pipe coupling, the manufacturing process, the benefits of using PPR coupling, and how to choose a reliable manufacturer.

What Are PPR Pipes and Their Couplings?

PPR pipes are thermoplastic pipes made from polypropylene random copolymer, a material known for its strength and lightweight characteristics. These pipes are flexible, resistant to corrosion, and can withstand temperatures ranging from -20°C to 95°C, making them ideal for hot and cold water systems.

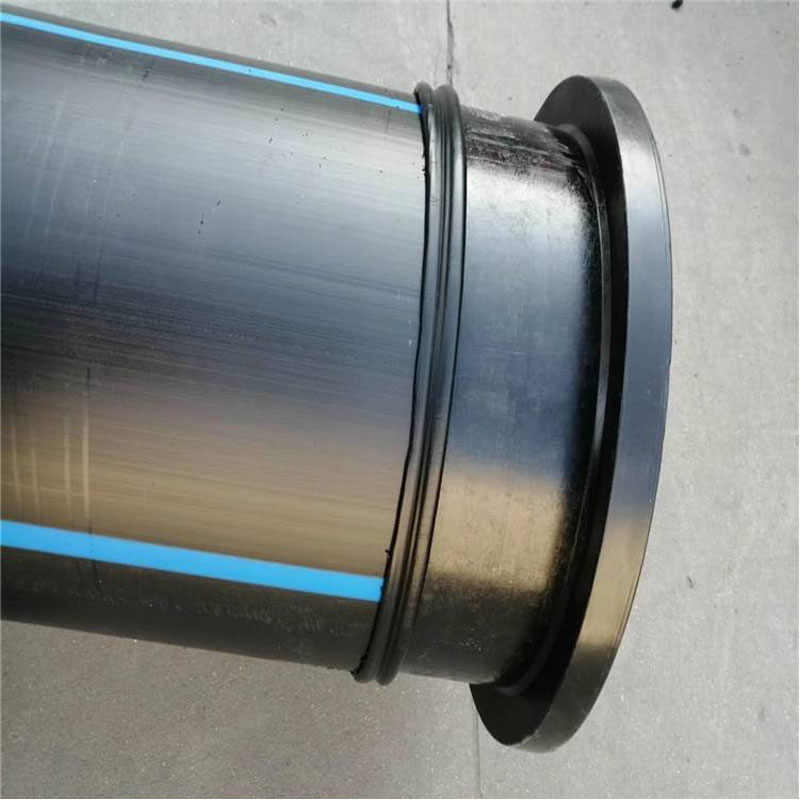

PPR couplings are essential components used to join two pieces of PPR pipes. They provide a secure and leak-proof connection, ensuring the integrity of the entire plumbing system. Couplings can come in various shapes and sizes, including elbows, tees, and straight connectors, allowing extensive customization based on the specific piping requirements.

The Manufacturing Process

The manufacturing of PPR pipe couplings involves several critical steps, ensuring the final product meets high standards of quality and performance. The process begins with the selection of high-grade polypropylene resin, which is extruded to form the pipes and fittings.

1. Extrusion The polypropylene resin is heated and melted to form a homogenous material. This molten plastic is then extruded through a die to create the desired shape of the pipe coupling.

2. Cooling After extrusion, the pipes and couplings are cooled using water or air to solidify the material, ensuring it maintains its shape.

3. Cutting and Trimming Once cooled, the extruded pieces are cut to the required lengths and trimmed to remove any excess material or imperfections.

4. Quality Control Each batch of produced PPR couplings undergoes rigorous quality control testing. This process includes checking for dimensional accuracy, wall thickness, and resistance to high pressure and temperature.

5. Packaging Finally, the finished products are sanitized, packaged, and ready for distribution to wholesalers, retailers, and direct consumers.

Benefits of Using PPR Pipe Couplings

ppr pipe coupling manufacturer

Choosing PPR pipe couplings offers several advantages

- Durability PPR couplings are resistant to corrosion, scale, and rust. They have a long lifespan, often exceeding 50 years when properly installed, reducing the need for frequent replacements.

- Temperature and Pressure Resilience They can handle high temperatures and pressures, making them suitable for a variety of applications, including residential, commercial, and industrial plumbing systems.

- Easy Installation PPR couplings are lightweight and easy to handle, allowing for quick and efficient installation. They can be joined using heat fusion techniques, which create a permanent bond.

- Cost-Effective While the initial investment in PPR piping systems may be higher than traditional materials like PVC, the long-term savings on maintenance and replacements make it a cost-effective choice.

Choosing a Reliable PPR Pipe Coupling Manufacturer

To ensure a high-quality product, it is crucial to select a reputable PPR pipe coupling manufacturer. Here are some tips for choosing the right one

1. Experience Look for manufacturers with a proven track record in the industry. Established companies are more likely to have the expertise and technology needed to produce high-quality products.

2. Certifications Check for industry certifications and standards, such as ISO 9001, which indicate that the manufacturer adheres to strict quality management systems.

3. Product Variety A reliable manufacturer should offer a wide range of PPR couplings and fittings to meet various needs and specifications.

4. Customer Support Consider manufacturers that provide excellent customer service, including technical support and guidance on installation.

Conclusion

PPR pipe coupling manufacturers play a vital role in the plumbing industry, providing essential components that ensure the functionality and reliability of piping systems. Understanding the advantages of PPR systems and the manufacturing process can help consumers make informed decisions when selecting products for their plumbing needs. With the growing demand for efficient and durable piping solutions, investing in high-quality PPR pipe couplings is a strategic choice for both professional plumbers and DIY enthusiasts alike.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025