Dec . 15, 2024 18:37 Back to list

ppr pipe 1 price factories

Understanding PPR Pipe and Its Pricing in Modern Factories

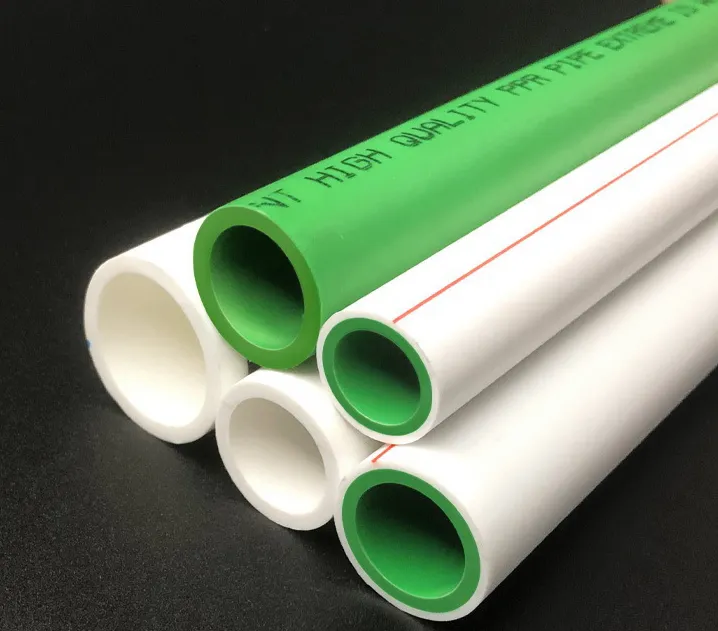

PPR pipes, also known as Polypropylene Random Copolymer pipes, are becoming increasingly popular for various plumbing and construction applications due to their durability, chemical resistance, and thermal stability. These pipes are often utilized in residential, industrial, and agricultural contexts for hot and cold water distribution, as well as for irrigation systems and compressed air installations. In this article, we will explore the factors that influence the pricing of PPR pipes, the role of factories in their production, and the current market trends.

What is PPR Pipe?

PPR pipes are made from a type of plastic that offers several advantages compared to traditional materials like metal or PVC. One of the primary benefits of PPR pipes is their ability to withstand high temperatures and pressures, making them ideal for hot water systems. Additionally, PPR is resistant to scale formation and corrosion, which ensures longevity and reduces maintenance costs.

The manufacturing process of PPR pipes involves the polymerization of propylene, which is then randomly copolymerized with ethylene. This results in a flexible yet strong material that can be molded into various sizes and shapes to meet specific application requirements. The versatility of PPR makes it an appealing choice for manufacturers and downstream users alike.

Factors Influencing PPR Pipe Prices

The pricing of PPR pipes depends on several factors, including raw material costs, production techniques, and market demand. Here are some of the key elements that affect pricing

1. Raw Material Costs The price of polypropylene resin, the primary raw material for PPR pipes, can fluctuate based on global oil prices and supply chain dynamics. In recent years, volatility in crude oil prices has led to significant changes in the cost of polypropylene, directly impacting the pricing of PPR pipes.

ppr pipe 1 price factories

2. Production Techniques Advanced manufacturing techniques can also influence the cost. Factories that utilize automated production lines and efficient quality control measures often produce higher quality pipes at lower operational costs. Therefore, manufacturers that invest in modern machinery and techniques might offer competitive pricing for their PPR products.

3. Market Demand The construction industry's demand for PPR pipes significantly affects pricing. In regions experiencing rapid development, the demand for plumbing materials, including PPR pipes, tends to increase, driving prices up. Conversely, in markets with a slowdown in construction activities, prices may stabilize or decrease.

4. Trade Policies Import tariffs and trade agreements can also play a crucial role in determining the price of PPR pipes. Countries that impose tariffs on imported materials can affect local pricing structures, making domestically produced PPR pipes more competitive.

Current Market Trends

As of late 2023, the PPR pipe market is witnessing several trends. The growing awareness of sustainable building practices and energy-efficient plumbing systems has led to increased demand for durable materials like PPR. Manufacturers are also focusing on eco-friendly production processes, which may influence pricing structures in the coming years.

Additionally, the rise of smart plumbing solutions incorporating PPR pipes suggests a shift towards more integrated building systems. This technological advancement may lead factories to innovate and improve product offerings, potentially impacting overall pricing.

Conclusion

In conclusion, PPR pipes are gaining traction in various sectors due to their numerous advantages. Understanding the factors that affect their pricing, including raw material costs, production techniques, and market dynamics, will enable buyers and manufacturers to make informed decisions. As the market trends evolve, staying abreast of developments within the PPR pipe industry will be essential for anyone involved in construction, plumbing, or manufacturing. By leveraging modern production capabilities and responding to market demands, factories can continue to produce high-quality PPR pipes that meet the needs of consumers while maintaining competitive pricing.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025