Feb . 20, 2025 12:20 Back to list

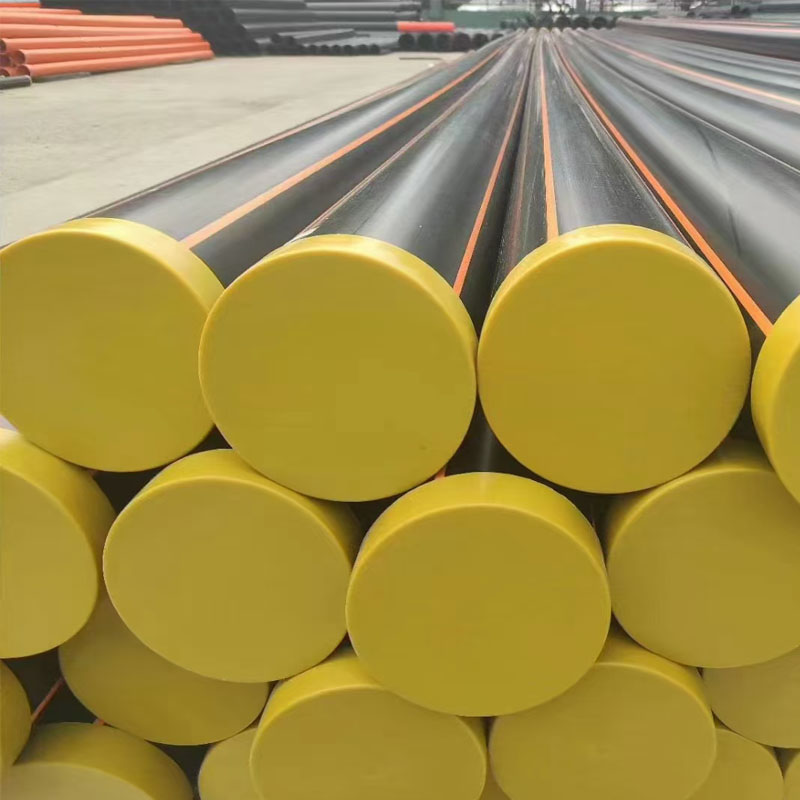

DN150 HDPE pipes for irrigation

Experience and Expertise Manufacturers with a long-standing history in the industry often have a wealth of experience that translates into refined manufacturing processes and high-quality products. These companies have witnessed the evolution of insulation technology and have adapted by enhancing their product offerings. Experience also fosters trust; customers can rely on the expertise of seasoned manufacturers who have consistently delivered reliable insulation solutions that perform at an optimal level in diverse environments. Customer Support and After-Sales Service Even the most advanced insulation products require adequate support from the manufacturer. Top-tier insulation providers distinguish themselves by offering robust customer service and after-sales support. This includes providing detailed installation guides, access to skilled technical support, and responsive after-sales services. Engaging with a supportive manufacturer can significantly ease the installation process and provide valuable assistance throughout the lifespan of the insulation. Environmental and Economic Considerations In recent years, the push for environmentally responsible manufacturing practices has influenced the production of PPR hot water pipe insulations. Manufacturers who prioritize sustainability employ methods that reduce waste, reuse materials, and minimize the carbon footprint of their products. Additionally, cost-effective manufacturing processes allow these companies to offer competitive pricing without sacrificing quality. This balance between environmental responsibility and economic feasibility is increasingly seen as a key determinant in selecting an insulation manufacturer. In conclusion, when choosing PPR hot water pipe insulation manufacturers, a thorough assessment of the product quality, innovation capacity, compliance with standards, and dedication to customer service is necessary. Prioritizing these factors will not only result in efficient and long-lasting insulation solutions but also align with evolving expectations for sustainable and cost-effective manufacturing practices. Whether installing new systems or upgrading existing ones, the right insulation can significantly impact thermal performance and energy conservation.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025