Feb . 20, 2025 10:50 Back to list

DN150 HDPE pipes for irrigation

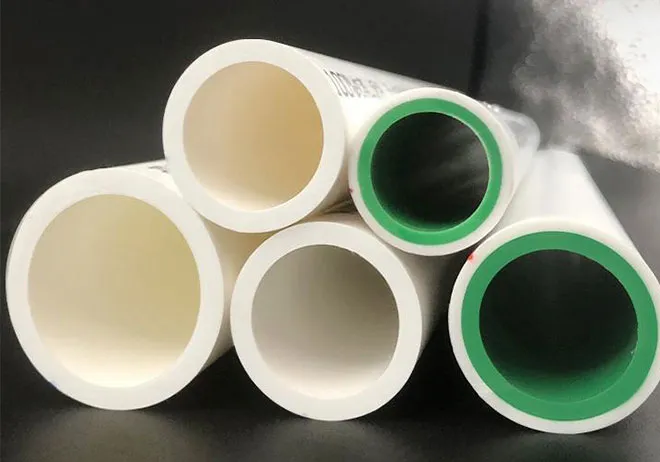

Safety Standards represent another crucial factor. A reliable insulation factory places a high priority on safety, ensuring that all insulation products are tested and certified to comply with internationally recognized safety standards. Insulation materials must resist not only regular wear and tear but also potential hazards such as fire, chemical exposure, and mechanical stress. A factory committed to safety equips you with peace of mind, affirming that the insulation materials used in your project are both reliable and safe for long-term use. Sustainability Initiatives form a pivotal aspect of modern insulation factories. Progressive factories adopt eco-friendly practices throughout the manufacturing process, focusing on reducing carbon footprints, and using sustainable resources. Their commitment to sustainability is reflected in the creation of energy-efficient products that contribute positively to the environment by reducing energy demand and lowering costs. In an age where sustainability is critical, choosing a factory driven by eco-conscious practices underscores a commitment to responsible building and energy conservation. Customer Support and Service excellence differentiate leading insulation factories from their counterparts. Exceptional customer care, from consultation to after-sales support, ensures that any concerns or questions regarding product application or performance are addressed promptly and effectively. Factories with a robust service framework are invaluable partners, aiding project success through expert advice and responsive communication. In conclusion, selecting a PPR hot water pipe insulation factory is not merely a procurement task; it involves evaluating a combination of quality, innovation, experience, safety, sustainability, and service. By recognizing a factory that excels in these areas, you ensure that your project benefits from high-performance insulation solutions that optimize energy efficiency, promote sustainability, and ensure safety. An investment in the right insulation factory is an investment in the future viability and efficiency of your infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025