Nov . 18, 2024 11:51 Back to list

PPR Cold Water Pipe Manufacturing Process and Best Practices for Optimal Quality

The Role of PPR Pipes in Cold Water Supply Systems

In modern plumbing and irrigation systems, the choice of materials is critical to ensuring efficiency, longevity, and safety. Polypropylene Random Copolymer (PPR) pipes have emerged as a leading option for cold water applications due to their unique properties and advantages. This article explores the significance of PPR pipes specifically for cold water, with a focus on their manufacturing processes, benefits, and applications.

What is PPR?

PPR, or Polypropylene Random Copolymer, is a thermoplastic polymer that is predominantly used for plumbing and piping systems. Its versatility and resistance to various chemicals make it ideal for a wide range of applications, especially in cold water systems. PPR pipes are manufactured using a specific extrusion process that ensures consistency and durability in the final product. The manufacturing process often takes place in specialized factories equipped with state-of-the-art technology to guarantee high-quality standards.

Manufacturing Process

The production of PPR pipes begins with the selection of high-quality polypropylene resin. The raw material is subjected to a series of processes including polymerization, extrusion, and cooling. During polymerization, the polypropylene is combined with a random copolymer to improve its performance characteristics. Following this, the mixture is melted and extruded into pipes of various diameters and lengths. After cooling, the pipes undergo rigorous quality checks to ensure they meet industry standards for pressure resistance, impact strength, and dimensional stability.

PPR pipe factories usually adhere to international standards, including ISO certifications, which ensure that the products are safe, reliable, and suitable for use in both residential and commercial applications.

Benefits of PPR Pipes for Cold Water

1. Corrosion Resistance One of the standout features of PPR pipes is their resistance to corrosion. Unlike metal pipes that can rust or degrade over time when in contact with water, PPR pipes are immune to such deterioration, ensuring a longer lifespan.

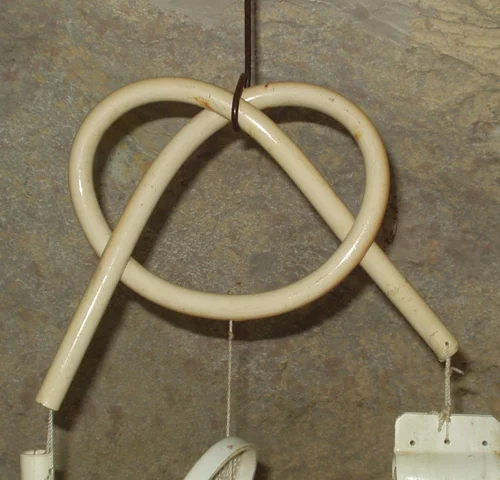

ppr cold water pipe factory

2. Low Thermal Conductivity PPR pipes have low thermal conductivity, which helps prevent heat loss in cold water systems. This property is particularly advantageous in maintaining consistent temperatures, leading to efficient water delivery.

3. Lightweight and Flexible The lightweight nature of PPR pipes makes them easy to handle and install. Their flexibility allows for a variety of installation techniques and configurations, reducing labor costs and time spent on installation.

4. Chemical Resistance PPR pipes are resistant to many chemicals, making them suitable for a range of applications beyond just cold water supply. This resistance helps in minimizing the risk of leaching harmful substances into the water supply.

5. Smooth Interior Surface The smooth interior of PPR pipes ensures minimal friction, which reduces the likelihood of blockages and enhances flow rates. This characteristic also minimizes the accumulation of deposits over time.

Applications of PPR Pipes

PPR pipes are widely used in various sectors, particularly in residential and commercial plumbing systems for cold water distribution. They are also utilized in irrigation systems, cooling systems, and even in industrial processes where cold water is required. As urbanization continues to grow, the demand for efficient and reliable water supply systems increases, making PPR pipes an ideal solution for new construction projects.

Conclusion

In summary, PPR pipes represent a remarkable advancement in the field of plumbing and water supply systems, particularly for cold water applications. Their corrosion resistance, lightweight nature, and superior performance characteristics make them a preferred choice for both manufacturers and consumers. As we move towards more sustainable and efficient plumbing solutions, the importance of high-quality PPR pipe factories cannot be overstated. Investing in PPR technology not only enhances the reliability of water delivery systems but also promotes environmental sustainability by reducing the need for frequent repairs and replacements. By choosing PPR pipes, stakeholders in the construction and irrigation industries can contribute to a greener future while ensuring the effective delivery of cold water.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025