Sep . 01, 2024 07:19 Back to list

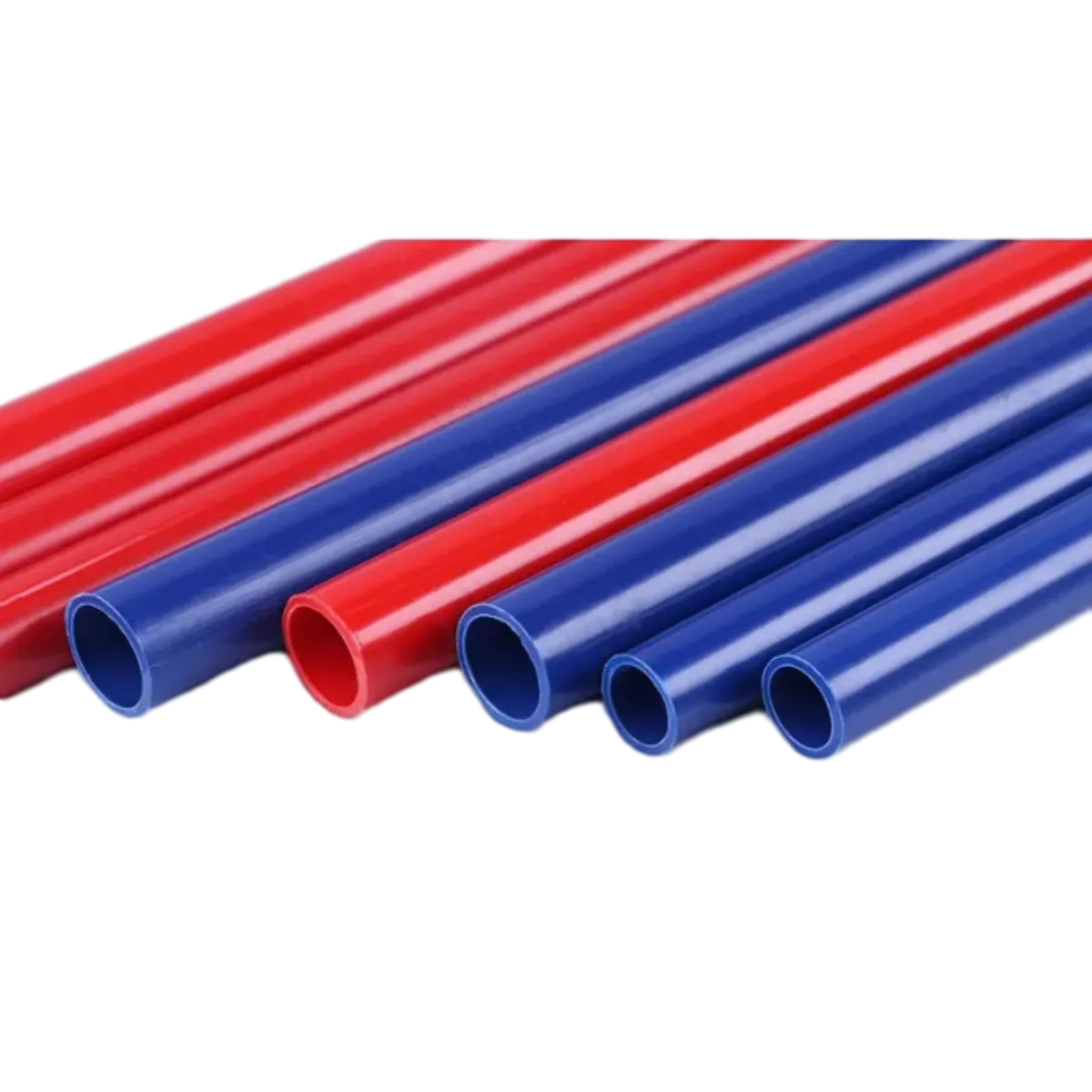

High-Quality PPR Tube Manufacturing Factory

The Rise of PPR Tube Factories A Sustainable Solution for Modern Plumbing

Polypropylene Random Copolymer (PPR) piping has gained significant traction as a preferred choice in modern plumbing systems due to its numerous advantages, including durability, flexibility, and resistance to corrosion. The growing awareness of sustainable practices and the need for high-quality plumbing solutions have led to an increase in the establishment of PPR tube factories worldwide. This article explores the rise of PPR tube factories and their pivotal role in the plumbing industry.

Understanding PPR Pipes

PPR pipes are made from a specific type of polypropylene that is designed to withstand high temperatures and pressures, making them ideal for both hot and cold water systems. Their seamless construction reduces the risk of leaks and ensures a consistent flow of water. Additionally, PPR pipes are lightweight, making them easy to transport and install, which further contributes to their popularity among contractors and builders.

The Growth of PPR Tube Factories

The increasing demand for reliable and eco-friendly plumbing materials has spurred the growth of PPR tube factories. These factories utilize advanced manufacturing technologies to produce high-quality PPR pipes that meet international standards. Many PPR tube factories are equipped with automated systems that enhance efficiency and quality control, allowing for the mass production of pipes with minimal waste.

Environmental Considerations

ppr tube factories

One of the significant advantages of PPR pipes is their environmental friendliness. Unlike traditional metal pipes, PPR pipes do not corrode or produce rust, which means they do not contaminate water supplies. Additionally, they are fully recyclable, making them a sustainable option for plumbing projects. As environmental regulations become more stringent, many construction firms and municipalities are turning to PPR tubes as a responsible alternative to traditional piping materials.

Economic Impact

The establishment of PPR tube factories has also created numerous economic opportunities. Factories generate jobs not only directly in manufacturing but also in associated fields such as logistics, marketing, and distribution. As these factories expand, they contribute to local economies and promote skills development in manufacturing and engineering sectors. Moreover, the ease of installation and longevity of PPR pipes can lead to cost savings for both contractors and homeowners, making them a smart investment in plumbing infrastructure.

Future Prospects

With continuous advancements in materials science, the future of PPR tube factories looks promising. Innovations such as anti-microbial coatings and improved heat resistance are already being explored to enhance the performance of PPR pipes. As the construction industry increasingly embraces smart technologies, the integration of IoT (Internet of Things) in PPR systems can provide real-time monitoring of pipeline conditions, further improving efficiency and safety.

Conclusion

PPR tube factories are playing a crucial role in the evolution of plumbing systems worldwide. Their ability to produce reliable, sustainable, and cost-effective piping solutions meets the demands of modern construction while supporting environmental goals. As the industry grows and technology evolves, PPR pipes are set to remain a leading choice for plumbing applications, underscoring the importance of these factories in shaping the future of infrastructure development. Industries must continue to innovate and optimize production processes to ensure that PPR tube factories can keep pace with the increasing demand for sustainable building practices.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025