Sep . 04, 2024 11:42 Back to list

ppr pipe coupling factory

PPR Pipe Coupling Factory Innovations in Plumbing Solutions

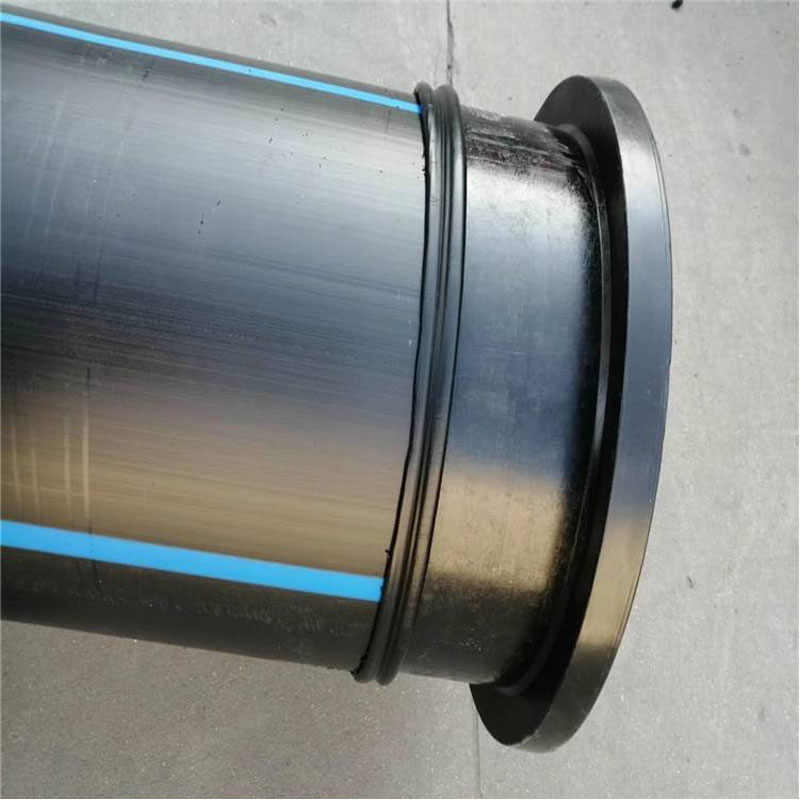

In recent years, the construction and plumbing industries have seen a significant shift towards more sustainable and reliable materials. Among these, PPR (Polypropylene Random Copolymer) pipes have emerged as a popular choice for both residential and commercial applications. As demand for PPR piping systems has increased, so has the importance of efficient and quality manufacturing processes. This is where PPR pipe coupling factories come into play, playing a crucial role in the production of high-quality coupling products that ensure seamless plumbing solutions.

PPR Pipe Coupling Factory Innovations in Plumbing Solutions

One of the key advantages of PPR pipe couplings is their resistance to corrosion and scale buildup. Unlike traditional metal pipes, PPR pipes do not rust, which makes them ideal for a variety of plumbing applications, including hot and cold water supply systems. Furthermore, PPR materials are lightweight and easy to handle, facilitating quicker installation due to reduced labor costs. In a fast-paced construction environment, this is a critical factor that contributes to project timelines.

ppr pipe coupling factory

Manufacturing processes in PPR pipe coupling factories have evolved significantly. Modern production techniques involve advanced machinery and technology, ensuring high precision and consistency in each product. Automated systems enhance the quality control measures in place, allowing for the monitoring of every step in the manufacturing process. This results in the production of couplings that meet international standards, assuring customers of their durability and performance.

Moreover, sustainable practices are increasingly being integrated into the operations of PPR pipe coupling factories. As awareness of environmental issues grows, manufacturers are adopting eco-friendly materials and methods. Recycling of plastic waste and energy-efficient machinery contributes to a reduced carbon footprint, aligning with global initiatives aimed at sustainability. These practices not only help in conserving resources but also resonate with environmentally-conscious consumers.

In terms of market trends, the demand for PPR pipe couplings continues to rise, driven by the growing construction industry and an increasing preference for modern plumbing solutions. The versatility of PPR pipes extends to various applications, such as irrigation, heating, and industrial water supply systems. As more builders and contractors recognize the benefits of using PPR products, the market for pipe coupling factories is likely to expand further.

In conclusion, PPR pipe coupling factories play a pivotal role in the plumbing industry by producing high-quality, durable, and sustainable coupling solutions. As the construction sector evolves, these factories must continue to innovate and adapt to meet the changing demands of the market. With advancements in technology and a commitment to sustainability, the future looks promising for PPR pipe coupling manufacturing, ensuring that it remains a cornerstone of efficient plumbing systems worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025