Sep . 01, 2024 19:51 Back to list

High-Quality PPR Pipe 63mm - Durable & Efficient Solutions

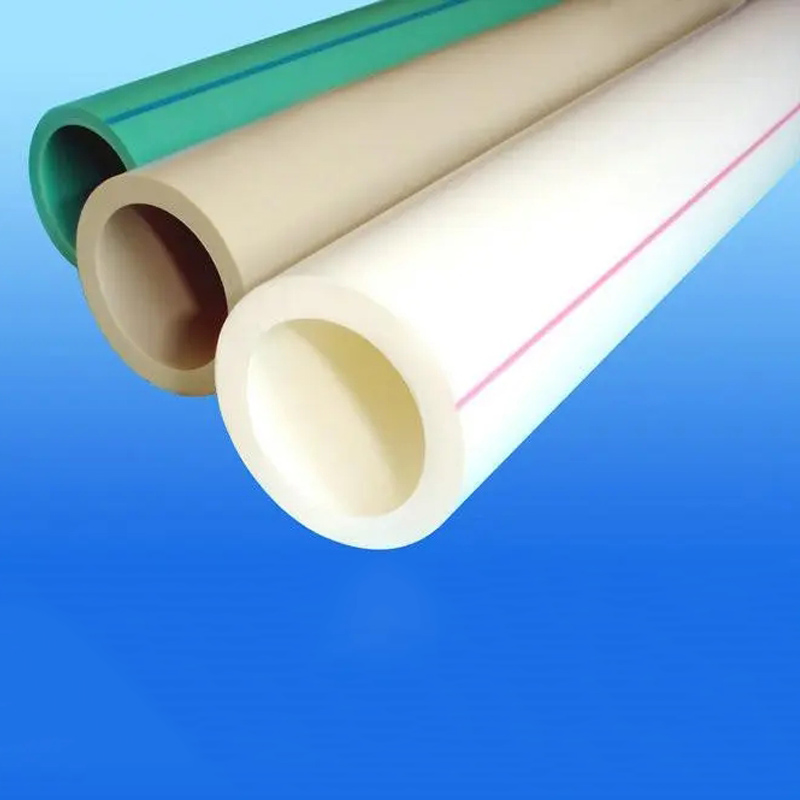

The Importance of Quality in PPR Pipe Manufacturing A Focus on 63mm Pipes

In the modern construction and plumbing industries, the demand for high-quality piping solutions is more critical than ever. Among these solutions, PPR (Polypropylene Random Copolymer) pipes have gained significant attention due to their durability, resistance to corrosion, and versatility. One of the most commonly used sizes in various applications is the 63mm PPR pipe, making it essential to explore the manufacturing processes and quality standards that define these products.

The Importance of Quality in PPR Pipe Manufacturing A Focus on 63mm Pipes

The manufacturing process of PPR pipes involves several crucial stages, starting from the selection of raw materials. High-quality polypropylene is chosen for its beneficial properties, such as flexibility, high-temperature resistance, and chemical stability. Once the raw material is selected, it undergoes an extrusion process where it is heated to form a molten state before being shaped into pipes. This stage requires precise temperature control and equipment maintenance to ensure the pipes achieve the desired thickness and structural integrity.

ppr pipe 63mm factory

After extrusion, the pipes are subjected to rigorous quality control measures. These measures typically include tests for dimensional accuracy, pressure resistance, and impact strength. For instance, 63mm PPR pipes must meet specific standards to ensure they can withstand various pressures and temperatures, given their applications in plumbing systems. Factories dedicated to producing high-quality PPR pipes often employ advanced technology and automated systems to enhance precision and reduce human error during manufacturing.

Furthermore, environmental considerations are becoming increasingly important in the manufacturing of PPR pipes. Factories now invest in eco-friendly practices, including recycling waste materials and minimizing energy consumption during production. Employing sustainable methods not only helps in reducing the environmental footprint but also appeals to a growing market of eco-conscious consumers.

In the competitive landscape of plumbing supplies, having a reliable source for 63mm PPR pipes can significantly influence project outcomes. Customers look for manufacturers who adhere to international quality standards, as these products are critical in maintaining the integrity of plumbing systems. By choosing pipes from reputable factories, consumers can ensure that their installations will be durable and less likely to require costly repairs or replacements in the future.

In conclusion, the manufacturing of 63mm PPR pipes is a complex process that requires attention to detail and a commitment to quality. As the demand for dependable plumbing solutions continues to rise, the emphasis on manufacturing excellence will be pivotal. By prioritizing quality control measures, sustainable practices, and innovation, manufacturers can meet the industry's needs and contribute to the development of reliable piping systems that stand the test of time.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025