Sep . 05, 2024 05:48 Back to list

High-Quality 50mm PPR Pipe Manufacturer | Durable & Reliable PPR Piping Solutions

Exploring PP-R Pipe 50mm Factory A Comprehensive Overview

In the realm of modern plumbing and construction, the choice of piping materials plays a crucial role in ensuring durability, efficiency, and cost-effectiveness. Among the various options available, polypropylene random copolymer (PP-R) pipes have emerged as a preferred choice for many industries. This article delves into the significance of a PP-R Pipe 50mm factory, the benefits of PP-R pipes, and the factors that contribute to successful manufacturing.

What is PP-R Pipe?

PP-R pipe is a type of plastic piping made from polypropylene, known for its resistance to high temperature and pressure. The random copolymer structure of PP-R provides enhanced performance compared to other types of plastics, making it suitable for both hot and cold water systems. A 50mm diameter is particularly popular as it balances flow capacity and ease of installation, making it a frequented choice for residential and commercial plumbing applications.

The Role of a PP-R Pipe Factory

A dedicated PP-R pipe factory is essential for the mass production of high-quality piping solutions. These factories utilize advanced manufacturing techniques to ensure consistency and quality in their products. State-of-the-art extrusion processes are employed to produce PP-R pipes, with a focus on maintaining the required specifications regarding diameter, wall thickness, and overall strength.

Additionally, quality control measures are instituted at every stage of production. Rigorous testing is conducted to evaluate the pipes' resistance to temperature fluctuations, pressure variations, and other external factors, ensuring that they meet international standards. These efforts not only boost product reliability but also enhance customer satisfaction.

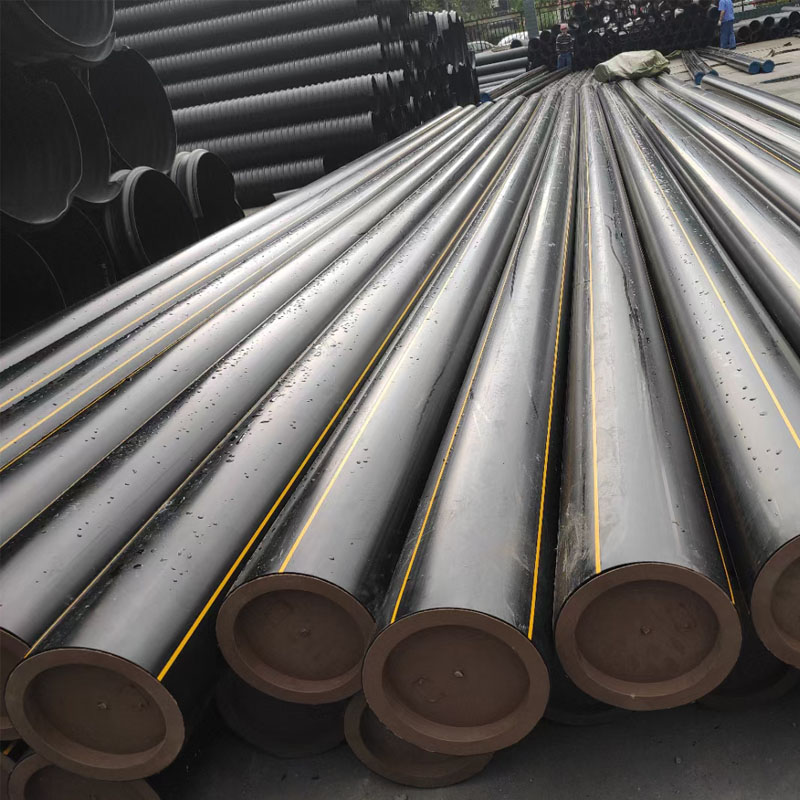

ppr pipe 50mm factory

Benefits of PP-R Pipes

One of the most significant advantages of utilizing PP-R pipes, particularly 50mm variants, is their excellent insulation properties. They maintain the temperature of the transported liquids longer, which minimizes heat loss during circulation. This feature is particularly beneficial in hot water systems, leading to energy savings and improved system efficiency.

Moreover, PP-R pipes are lightweight yet sturdy, facilitating easier handling and installation. Their smooth surface reduces friction, permitting higher flow rates and less energy consumption. Additionally, these pipes are resistant to corrosion, scale, and bacteria, making them a hygienic choice for potable water applications.

Environmental Considerations

Manufacturing PP-R pipes also emphasizes sustainable practices. Many factories focus on reducing waste during production and may use recycled materials in their processes. Additionally, the longevity and durability of PP-R pipes mean fewer replacements over time, which contributes to reduced environmental impact.

Conclusion

In conclusion, a PP-R Pipe 50mm factory is pivotal in meeting the growing demand for reliable and efficient piping solutions in the construction and plumbing sectors. The unique properties of PP-R pipes, combined with advanced manufacturing techniques, result in a product that not only performs excellently but also adheres to environmental sustainability practices. As the industry evolves, the role of such factories will undoubtedly expand, reflecting the increasing emphasis on quality and sustainability in construction materials.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025