Nov . 03, 2024 11:37 Back to list

orange pvc pipe factory

The Rise of Orange PVC Pipe Factories A Closer Look

In recent years, the construction and plumbing industries have observed a significant shift towards the use of polyvinyl chloride (PVC) pipes, particularly the vibrant orange variety. These pipes have gained popularity for their durability, ease of installation, and resistance to corrosion. This article explores the burgeoning orange PVC pipe factories, their production processes, advantages, and the future trajectory of this industry.

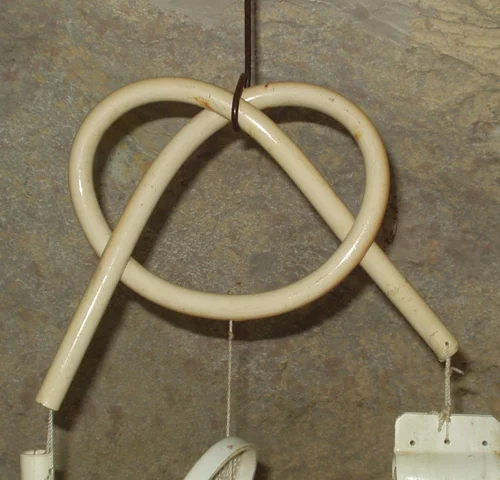

PVC pipes come in various colors, each designated for specific uses. Orange PVC pipes, for example, are mainly used in the transportation of sewage and stormwater. The distinct color not only helps in identification but also plays a crucial role in ensuring that the pipes are used for their intended purposes. Factories producing these orange PVC pipes have become instrumental in meeting the growing demand for efficient drainage and waste management systems in urban areas.

The Rise of Orange PVC Pipe Factories A Closer Look

One of the primary advantages of orange PVC pipes is their ability to withstand harsh environmental conditions. Unlike traditional metal pipes, which can corrode over time, PVC pipes are not susceptible to rust or decay. This longevity results in lower maintenance costs and fewer replacements, appealing to both contractors and property developers.

orange pvc pipe factory

Furthermore, the lightweight nature of orange PVC pipes makes them easier to transport and install, reducing labor costs. Their flexibility allows them to adapt to various terrains during installation, making them suitable for a range of projects, from residential to large-scale commercial developments. As urbanization continues to rise globally, the demand for efficient wastewater and drainage systems is likely to increase, thereby propelling the expansion of orange PVC pipe factories.

Environmental concerns also play a pivotal role in the increased adoption of PVC pipes. The manufacturing process has evolved, with factories implementing sustainable practices such as recycling scrap PVC and utilizing eco-friendly additives. Many manufacturers are committed to minimizing their carbon footprint, which has become a selling point in an increasingly eco-conscious market.

Looking ahead, the future of orange PVC pipe factories appears promising. With ongoing advancements in manufacturing technology and heightened awareness about sustainable building practices, these factories are well-positioned to innovate. Emerging technologies, such as smart pipe systems equipped with sensors for monitoring water quality and flow, could revolutionize how we manage our infrastructure.

In conclusion, the rise of orange PVC pipe factories reflects broader trends in construction and environmental sustainability. As cities expand and the need for efficient infrastructure grows, these factories are not just suppliers of materials but also contributors to a more sustainable and resilient urban landscape. The bright future of orange PVC pipes promises not only improved waste management but also a commitment to sustainable practices that benefit both the economy and the environment.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025