Aug . 14, 2024 04:40 Back to list

Manufacturing High-Quality Sink Inlet Pipes for Efficient Plumbing Solutions and Reliable Performance

The Importance of Quality Sink Inlet Pipes A Focus on Manufacturing

In the realm of plumbing and drainage systems, the effectiveness and durability of sink inlet pipes are critical components that ensure seamless water flow and prevent leaks. The manufacturing of these pipes encompasses a variety of techniques and materials, each chosen to meet stringent safety and performance standards. In this article, we’ll explore the importance of quality sink inlet pipes and the factors that contribute to their production in a factory setting.

Sink inlet pipes serve as essential conduits for directing water from various sources, such as sinks, bathrooms, and kitchens, into the drainage system. Their design might seem straightforward, but the engineering involved is quite sophisticated. Quality pipes must withstand various pressures, resist corrosion, and maintain structural integrity under different environmental conditions. Therefore, it is vital that these components are manufactured with precision and care.

The Importance of Quality Sink Inlet Pipes A Focus on Manufacturing

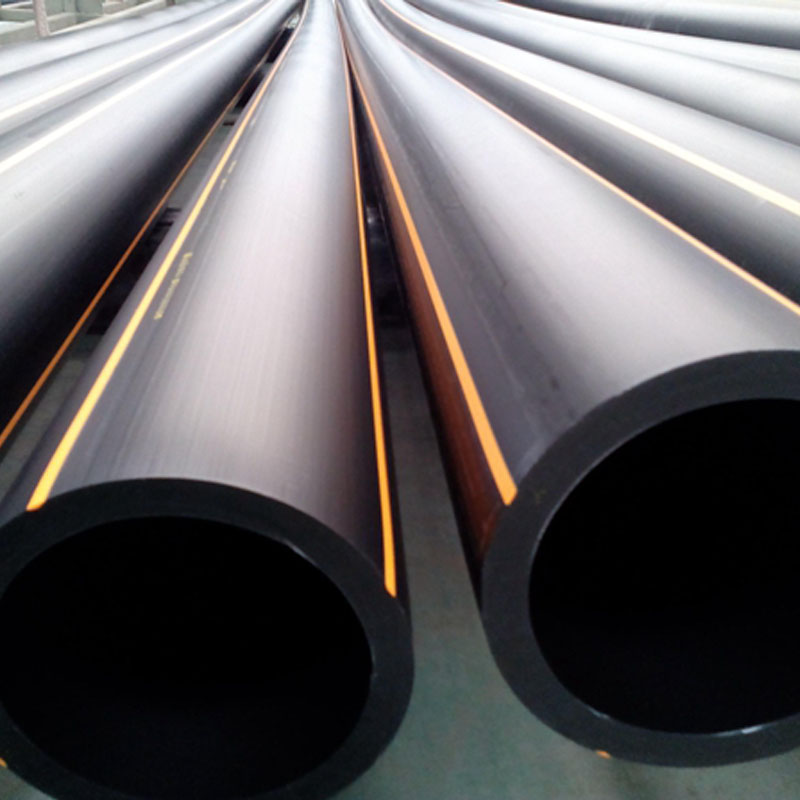

The manufacturing process typically involves several key steps extrusion, cutting, and inspection. During the extrusion phase, raw PVC material is heated and forced through a die to create long, continuous lengths of pipe. This method ensures uniform thickness and eliminates weak points often found in other manufacturing techniques. Once the pipe is extruded, it is cooled and then cut to the necessary specifications based on customer needs and industry standards.

sink inlet pipe factory

Quality control is paramount in the production of sink inlet pipes. Each batch of pipes undergoes rigorous testing to ensure they meet industry regulations. This can include tests for pressure tolerance, leak resistance, and overall durability. Factories are equipped with advanced technology that allows for real-time monitoring of production parameters and immediate identification of any anomalies. Such diligence not only protects the integrity of the product but also enhances the reputation of the manufacturer.

Moreover, sustainability has emerged as a significant consideration in the production of sink inlet pipes. Many factories are adopting environmentally friendly practices, such as recycling scrap materials and reducing waste. The use of eco-friendly manufacturing processes not only helps the environment but also appeals to an increasingly eco-conscious consumer base.

In addition to materials and manufacturing processes, design also plays a crucial role in the functionality of sink inlet pipes. Manufacturers are increasingly incorporating features such as smooth internal surfaces to reduce friction and improve water flow, as well as advanced coupling systems for easier installation and maintenance.

As urbanization continues to rise, the demand for efficient plumbing solutions, including sink inlet pipes, is expected to grow. Therefore, manufacturers must stay ahead of the curve, continuously researching new materials, technologies, and techniques to enhance product performance.

In conclusion, the manufacturing of sink inlet pipes is a multifaceted process that requires a combination of quality materials, advanced technology, and strict quality control. As these components form the backbone of effective drainage systems, investing in high-quality pipes will ultimately lead to improved plumbing solutions and greater customer satisfaction. The evolution of manufacturing practices, particularly with an emphasis on sustainability and innovation, will shape the future of this essential industry, ensuring that it meets the demands of modern society.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025