Nov . 06, 2024 02:17 Back to list

Manufacturer of Kitchen Sink Water Drainage and Plumbing Solutions for Homeowners

Understanding Kitchen Sink Water Pipe Manufacturers

When it comes to the integral components of our kitchens, water pipes play a critical role. As the heart of the plumbing system, these pipes ensure that clean water flows into our sinks while effectively removing wastewater. With the high demand for reliable plumbing solutions, kitchen sink water pipe manufacturers have become vital in the construction and renovation sectors. This article delves into the role of these manufacturers, the materials they utilize, the technologies they embrace, and the considerations homeowners should keep in mind when selecting water pipes.

The Role of Kitchen Sink Water Pipe Manufacturers

Kitchen sink water pipe manufacturers are responsible for designing and producing pipes suitable for both residential and commercial use. They take into account the specific requirements of kitchen plumbing systems, including factors like pipe diameter, pressure tolerance, and resistance to corrosion. The manufacturers often work in collaboration with contractors, builders, and designers to ensure their products meet industry standards and regulations.

These manufacturers also play a crucial role in innovation. As technology evolves, so do the materials and methods used in producing water pipes. Many manufacturers invest in research and development to create more efficient, durable, and environmentally friendly plumbing solutions. This commitment to innovation not only benefits the manufacturers but also the consumers who rely on their products for everyday use.

Materials Used in Water Pipe Manufacturing

The choice of materials is paramount in the kitchen sink water pipe manufacturing process. Common materials include

1. PVC (Polyvinyl Chloride) Widely used for its lightweight and corrosion-resistant properties, PVC is a popular choice for drain and waste pipes. It is also cost-effective and easy to install.

2. CPVC (Chlorinated Polyvinyl Chloride) This is a modified version of PVC that can withstand higher temperatures. It is commonly used for hot water supply lines, making it a versatile option for kitchen plumbing.

3. PEX (Cross-Linked Polyethylene) PEX is becoming increasingly popular due to its flexibility and resistance to scale and chlorine. It can expand, which makes it less likely to burst in freezing temperatures. Moreover, it is easy to install, allowing for quicker plumbing projects.

4. Copper A traditional material used in plumbing, copper is valued for its durability and natural antimicrobial properties. However, its high cost and the complicated installation process are considerations for manufacturers when choosing materials.

5. Stainless Steel Known for its corrosion resistance and longevity, stainless steel is often used in complex plumbing systems. However, it can be relatively pricey compared to other materials.

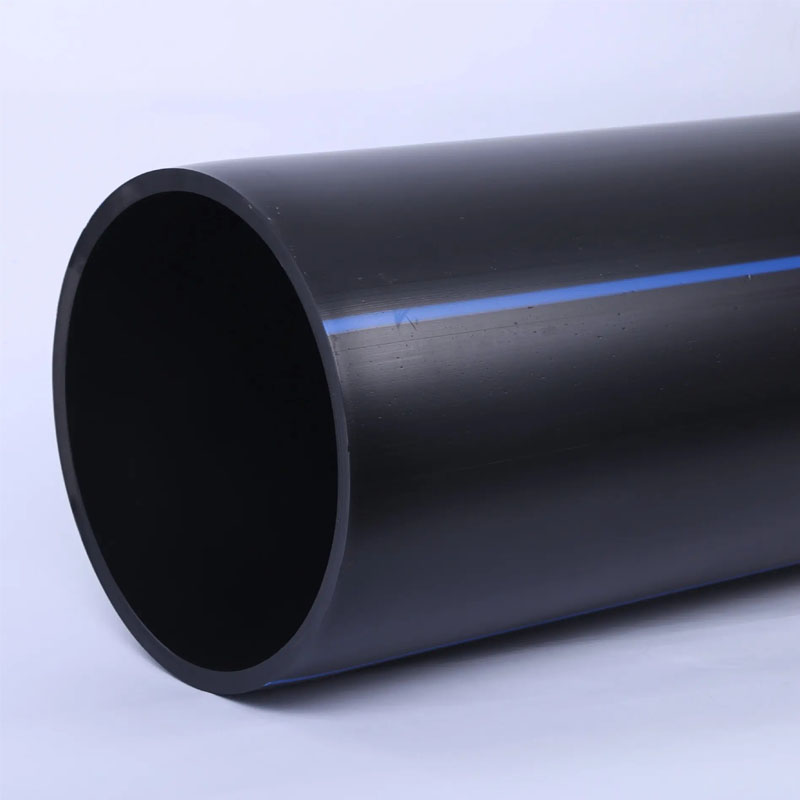

kitchen sink water pipe manufacturer

Each of these materials has its own set of advantages and disadvantages, and the choice often comes down to the specific needs of a project as well as budgetary constraints.

Technological Advancements in Manufacturing

The manufacturing process for kitchen sink water pipes has seen significant advancements in technology

. Automation plays a crucial role in enhancing production efficiency and ensuring consistent quality. Companies now employ advanced machinery that can produce pipes with precision, minimizing waste and reducing costs.Moreover, the rise of smart plumbing solutions has begun to influence how manufacturers design pipes. Integrating sensors into systems allows for real-time monitoring of water flow and pressure, enabling homeowners to detect leaks early and conserve water. Manufacturers that embrace these technologies not only cater to modern needs but also contribute to sustainable practices.

Key Considerations for Homeowners

When selecting kitchen sink water pipes, homeowners should consider the following factors

1. Material Evaluate the benefits and drawbacks of each material. Consider factors such as flexibility, cost, and expected lifespan.

2. Installation Choose a material that aligns with your budget and the skill level of the installer. Some materials may be easier for DIY installation compared to others.

3. Local Codes Always check local plumbing codes to ensure compliance with regulations when selecting materials for installation.

4. Manufacturer Reputation Research the manufacturer’s track record for quality and customer service. Look for reviews and recommendations when making your choice.

5. Environmental Impact Consider opting for manufacturers that prioritize sustainability in their production processes, using recycled materials and offering eco-friendly solutions.

In conclusion, kitchen sink water pipe manufacturers serve a vital function in ensuring our plumbing systems operate effectively and efficiently. By understanding the materials they use, the technologies they implement, and the considerations we should keep in mind, we can make informed decisions that enhance the functionality and longevity of our kitchen plumbing. As technology progresses and demands shift, these manufacturers will continue to play a crucial role in the evolution of kitchen plumbing solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025