Dec . 02, 2024 11:34 Back to list

Importance and Operation Guide of PPR Pipe Heating Time

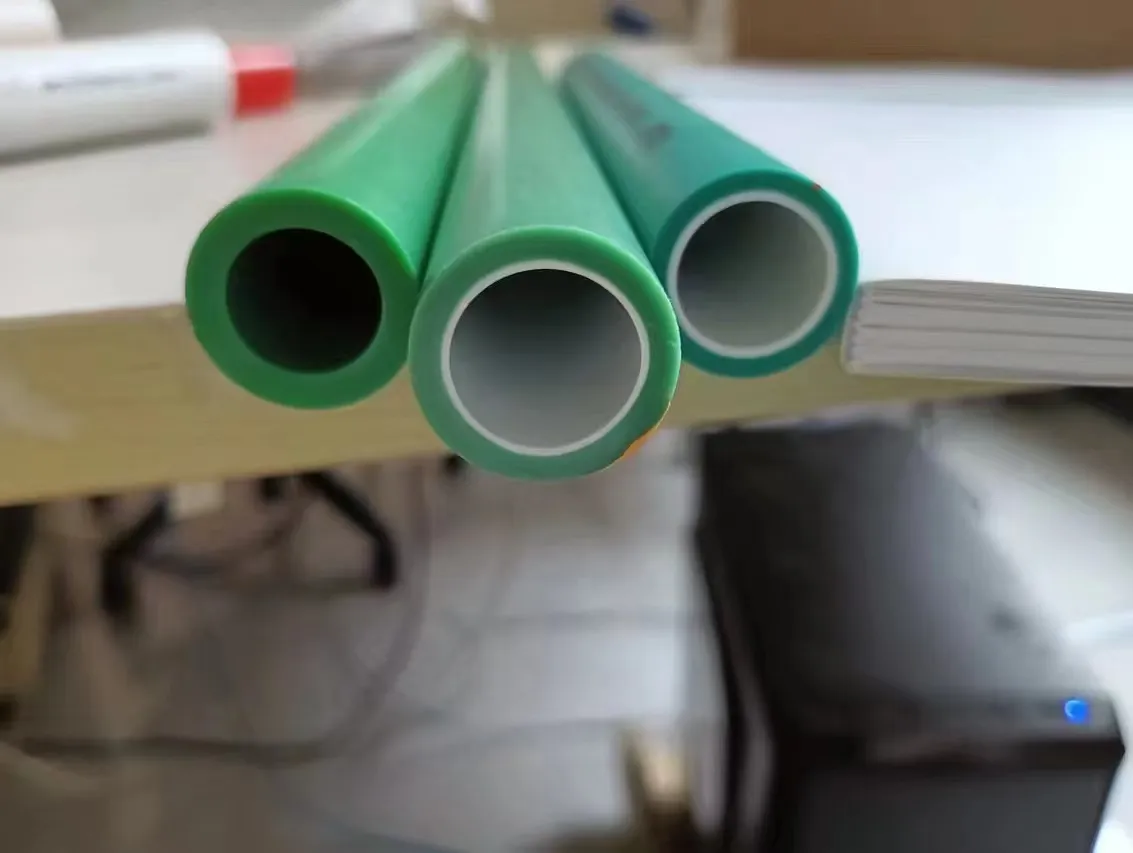

PPR plumbing, that is, polypropylene random copolymer pipe, has been widely used in water supply, heating and drainage fields because of its good heat resistance, pressure resistance and corrosion resistance. China 25mm HDPE pipes, PPR pipe heating time is a crucial link in the installation process, which is directly related to the quality and safety of pipe connections.

I. The Importance Of PPR Pipe Heating Time

The connection of ppr tube usually adopts hot melt connection, that is, the end faces of two pipes are heated to a molten state, and then they are quickly butted, and the close connection is realized by using the thermoplasticity of materials. The length of ppr pipe heating time has a direct impact on the connection quality. If ppr pipe heating time is too long, kitchen sink hot cold water lines will be deformed or even burnt due to excessive heating, which will not only affect the tightness of the connection, but also reduce the pressure-bearing capacity. On the other hand, if ppr pipe heating time is too short, the end face of the pipeline will not be fully melted, and cold joints or delamination will occur after docking, which will also lead to loose connection and the risk of water leakage.China 25mm HDPE pipes

II. The Determination of PPR Pipe Heating Time

PPR pipe heating time is not invariable, it depends on the specification and model of ppr tube, the performance of the heating equipment and the experience of the operator. Generally speaking, the larger the pipe diameter, the longer the heating time is required. For example, the heating time of D20PPR tube is usually 5 seconds, D25PPR tube is 7 seconds, and D32PPR tube is 8 seconds. These times are for reference only and need to be adjusted according to the specific situation in actual operation.

It is worth noting that ppr pipe heating time should be calculated from the time when the end face of the pipeline completely enters the heating mold, not from the time when the pipeline starts to push into the heating equipment. Because it takes a certain time for ppr water line to be pushed in, if the time is counted from this time point, the heating time of the end face of the last pushed pipeline will be insufficient, which will affect the connection quality.China 25mm HDPE pipes

III. The Operation Guide of PPR Pipe Heating Time

Step 1: Preparation.

Before the heating operation, ensure that the heating equipment is in good working condition and the heating die is clean and free of impurities. At the same time, check whether the end face of ppr water line is smooth and free of scratches to ensure the connection quality.

Step 2: Heating operation

Slowly push the end face of ppr tube into the heating mold until it enters completely. Pay attention to controlling the push-in speed to avoid uneven heating caused by too fast. Determine the heating time according to the specifications of ppr tube, and take out ppr water line immediately after reaching the predetermined time.

Step 3: Docking operation

After ppr water pipes are taken out, the end faces of the two pipes are quickly butted, and a certain pressure is applied for several seconds to fully fuse the molten materials. During the docking process, ensure that the end faces of ppr tube are completely aligned to avoid dislocation or inclination.

Step 4: Check and Adjust

After the docking is completed, check whether the connection parts are smooth and free of bubbles and cold joints. If there is any abnormality, it should be adjusted or reconnected immediately.China 25mm HDPE pipes

Step 5: Cooling and Curing.

After the connection is completed, let ppr water line naturally cool to room temperature. During the cooling process, avoid applying external force or other operations to the connection parts, so as not to affect the connection quality.

IV. Matters Needing Attention of PPR Pipe Heating Time

- PPR pipe heating timeshould be strictly controlled, not too long or too short.

- During the heating process, keep the heating die clean and dry to avoid impurities affecting the connection quality.

- The end face of ppr plumbingshall be smooth and scratch-free, to ensure a tight connection.

- In the process of docking, the alignment and stability of the end face of ppr plumbingshould be maintained to avoid dislocation or inclination.

- After the connection is completed, strict inspection and testing should be carried out to ensure that the connection quality meets the standards.

To sum up, ppr pipe heating time is one of the key factors affecting the connection quality. By strictly controlling heating time, optimizing heating operation and strengthening quality inspection and testing, the safety and reliability of ppr plumbing connection can be ensured. In practical application, ppr pipe heating time should be flexibly adjusted according to the specific situation, and the standardized operation flow should be followed to ensure the normal operation and long-term stability of ppr piping system.

-

hdpe-tube-pipe-in-coil-packaging

NewsAug.22,2025

-

kitchen-sink-water-lines-25mpa-pressure-resistance

NewsAug.22,2025

-

submersible-column-pipe-for-desert-irrigation

NewsAug.22,2025

-

hdpe-sewer-pipe-with-no-leakage-feature

NewsAug.22,2025

-

hdpe-reducer-coupling-our-promise-of-precision

NewsAug.22,2025

-

hdpe-drip-pipe-our-legacy-of-efficiency

NewsAug.22,2025