Dec . 02, 2024 11:31 Back to list

HDPE Pipe Size Chart-A Comprehensive Guide

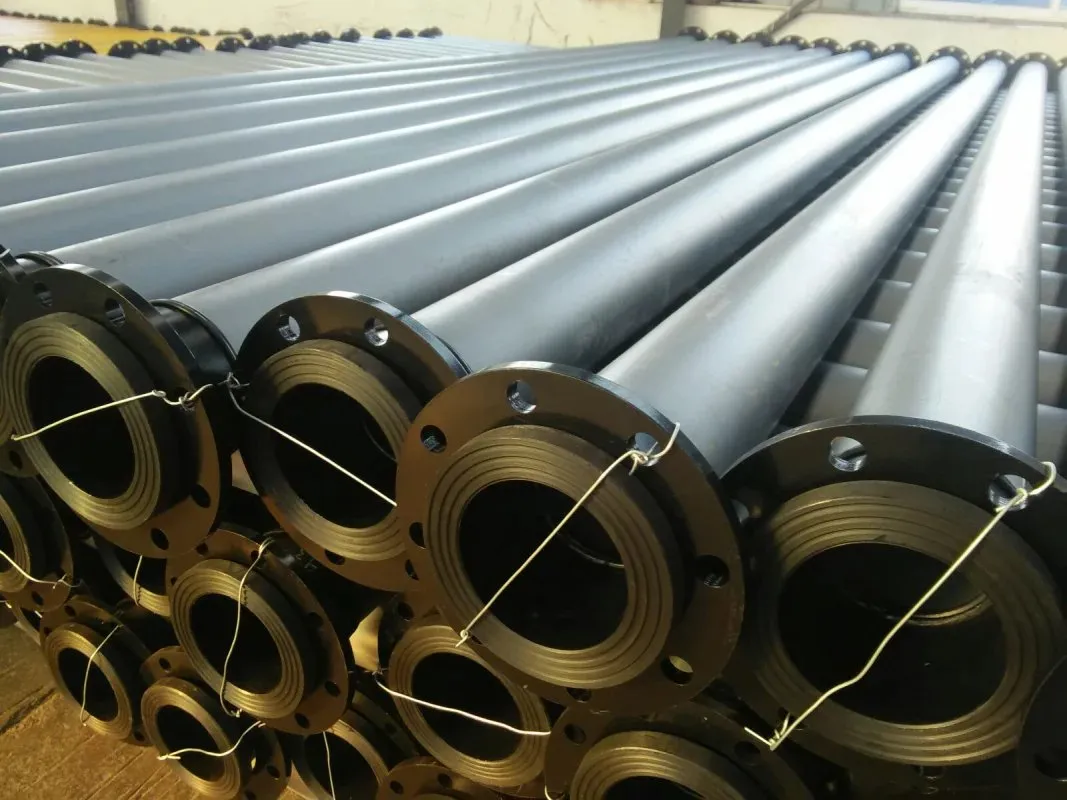

HDPE (High-Density Polyethylene) pipes have revolutionized the piping industry due to their durability, flexibility, and corrosion resistance. They are widely used in various applications, including water supply, drainage systems, gas transportation, and industrial processes. Understanding china 25mm HDPE pipe size chart is crucial for efficient installation and maintenance.

HDPE Pipe Dimensions in HDPE Pipe Size Chart

HDPE tubing are manufactured in a range of diameters to suit different applications. The standard diameters, often referred to as nominal diameters, are typically expressed in millimeters (mm) or inches. Common diameters range from small, such as 20mm or ½ inch, to large, such as 2000mm or more for marine applications.

HDPE pipe size chart includes both the outer diameter (OD) and the inner diameter (ID). The outer diameter is the measurement from one side of the pipe to the other, including the wall thickness. The inner diameter is the measurement of the open space inside the pipe where fluid flows.

Wall Thickness Factor in HDPE Pipe Size Chart

Wall thickness is another critical factor in hdpe irrigation pipe fitting specifications. It determines the pipe's pressure rating and overall strength. Thicker walls can withstand higher pressures and provide greater durability, making them ideal for applications where robustness is key. This enhanced structural integrity not only ensures the longevity of hdpe flexible irrigation pipe but also reduces the risk of failure, thereby safeguarding the integrity of the system it's a part of. By considering factors such as material type, environmental conditions, and the specific application, engineers can specify the perfect pipe to meet both safety and performance standards, promoting a reliable and efficient infrastructure.

China 25mm HDPE pipes It is essential to comprehend wall thickness in hdpe tubing systems to guarantee structural soundness and appropriate operation. Typically measured in millimeters (mm), wall thickness is frequently classified using a standard dimension ratio (SDR). This SDR, which determines the pipe's durability and ability to withstand internal pressure, is the ratio of the pipe's outer diameter to wall thickness. An SDR 11 pipe, for instance, strikes a compromise between strength and flexibility by having a wall thickness that is one-eleventh of its outer diameter. On the other hand, thicker walls with lower SDR values can withstand higher pressure ratings, making them appropriate for more demanding applications. Engineers may choose the ideal pipe for a range of applications, from gas transmission to water distribution, with confidence in the capacity of hdpe water supply pipe to carry out its intended function safely and effectively thanks to this ratio, which is a fundamental component of pipe design.

Pressure Ratings in HDPE Pipe Size Chart

Water supply hdpe pipe are rated for specific pressure levels based on their wall thickness and diameter. Hdpe pipe dimensions highly consider in pressure ratings are crucial for ensuring the pipe's structural integrity and safety in various applications.

Pressure ratings are typically expressed in bars, psi (pounds per square inch), or PN (pressure nominal) ratings. For instance, PN10 pipes are designed to withstand a pressure of 10 bar. The pressure rating of a pipe decreases as its diameter increases, as larger pipes require thicker walls to maintain the same pressure rating. China 25mm HDPE pipes

Common Sizes and Specifications in HDPE Pipe Size Chart

Below is a sample HDPE pipe size chart detailing common diameters, wall thicknesses, and pressure ratings:

|

Nominal Diameter (mm/inch) |

20 /0.75 |

25 /1 |

32 /1.25 |

40 /1.5 |

50 /2 |

63 /2.5 |

63 /2.5 |

75 /3 |

90 /3.5 |

110 /4.25 |

160 /6.25 |

|

Outer Diameter (mm) |

22.2 |

28.3 |

35.5 |

44.2 |

56.8 |

69.9 |

69.9 |

84.8 |

100.3 |

122.6 |

176.5 |

|

Wall Thickness (mm) |

2.1 |

2.6 |

3.3 |

3.8 |

4.8 |

5.6 |

5.6 |

6.7 |

7.9 |

9.6 |

13.6 |

|

SDR |

10.6 |

10.9 |

10.8 |

11.7 |

11.8 |

12.5 |

12.5 |

12.6 |

12.7 |

12.8 |

13 |

|

Pressure Rating (PN/bar) |

PN16 |

PN16 |

PN16 |

PN12.5 |

PN10 |

PN10 |

PN10 |

PN8 |

PN6.3 |

PN6.3 |

PN4 |

Applications and Considerations in HDPE Pipe Size Chart

When selecting hdpe pipe sizes and dimensions, it's essential to consider the specific application, required pressure rating, and environmental conditions. For example, hdpe pipe for potable water used in underwater applications require thicker walls and higher pressure ratings to withstand the hydrostatic pressure. Like hdpe pipe 24 inch.

In cold climates, HDPE pipes with thicker walls are preferred to prevent brittle failure at low temperatures. Additionally, the installation method, such as trenchless or open-cut, can affect the pipe's selection. Trenchless installation methods often require pipes with stiffer walls to maintain their shape during installation.

HDPE pipe size chart is a valuable tool for engineers, contractors, and installers to select the appropriate pipe specifications for various applications. By understanding the relationship between diameter, wall thickness, and pressure rating, professionals can ensure the safe and efficient installation of HDPE pipes. With their durability, flexibility, and corrosion resistance, hdpe tubing continue to be a preferred choice for a wide range of piping systems.China 25mm HDPE pipes.

The inherent properties of HDPE—its ability to flex without breaking, its resistance to chemicals that might corrode other materials, and its longevity even in extreme conditions—make it a standout choice for both above-ground and underground installations. By consulting HDPE pipe size chart, professionals can make informed decisions that lead to the creation of robust, cost-effective, and sustainable piping solutions that meet the needs of modern infrastructure projects.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025