Nov . 10, 2024 19:47 Back to list

HDPE to Steel Transition Coupling Solutions for Efficient Pipeline Connectivity

HDPE to Steel Transition Coupling A Comprehensive Overview

In the world of piping systems, the transition from High-Density Polyethylene (HDPE) to steel pipes is a crucial consideration for engineers and contractors. The transition coupling plays a vital role in facilitating a seamless connection between these two different materials, each with its unique properties and applications. In this article, we will explore the significance of HDPE to steel transition couplings, their design, applications, advantages, and best practices in installation.

Understanding HDPE and Steel in Piping Systems

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio. It is lightweight, flexible, resistant to chemicals, and highly durable, making it an ideal choice for various applications, particularly in water and gas distribution systems. HDPE pipes are commonly used in trenchless installations, irrigation, and sewer systems due to their corrosion resistance and ease of installation.

On the other hand, steel pipes, often made from carbon steel, are renowned for their strength and resistance to high pressures. They are commonly used in applications that require high mechanical strength, such as in oil and gas transport, industrial water systems, and structural applications. However, steel is susceptible to corrosion, which necessitates protective coatings or cathodic protection.

The Role of Transition Couplings

Transition couplings serve as essential components in systems where HDPE and steel come together. These couplings are specifically designed to absorb the differences in material properties, allowing for a secure and leak-free connection. They typically consist of materials that can withstand the pressures and environmental conditions associated with both HDPE and steel applications.

Design Features

A well-designed transition coupling will incorporate features that accommodate the physical and chemical properties of HDPE and steel. Key design considerations include

1. Material Selection Transition couplings are often made from corrosion-resistant materials such as stainless steel or specialized polymers to ensure longevity and reliability.

2. Size Compatibility Couplings must be available in various sizes to fit multiple pipe diameters. Proper sizing ensures that the transition between different materials does not create stress concentrations that could lead to failure.

3. Flexibility and Adaptability The coupling should allow for thermal expansion and contraction differences between HDPE and steel to prevent joint failure. 4. Pressure Rating The coupling must be rated for the same or higher pressure levels as the respective pipe materials to prevent leakage or ruptures.

Applications of HDPE to Steel Transition Couplings

Transition couplings are crucial in various industries, including

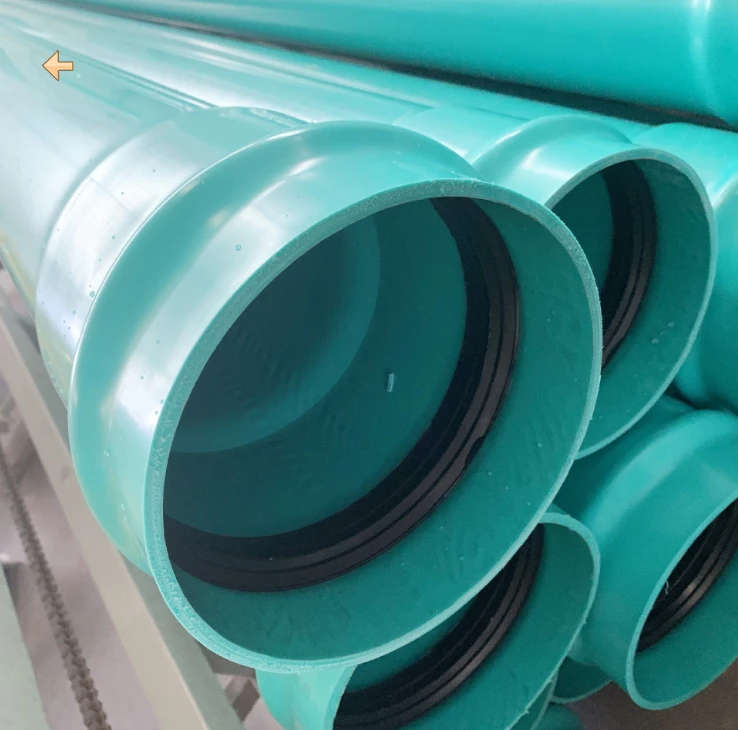

hdpe to steel transition coupling product

- Water Supply Systems Connecting HDPE pipes used for water distribution to steel pipes that serve as main lines or connections to treatment facilities. - Gas Distribution Used in natural gas pipelines, where HDPE is often employed in residential applications and needs to transition to high-pressure steel pipes.

- Chemical Transportation Where resilient HDPE is preferred for its chemical resistance but requires a secure connection to steel infrastructure

.Advantages of Using Transition Couplings

1. Ease of Installation Transition couplings simplify the process of joining two different piping materials, reducing installation time and labor costs.

2. Enhanced System Integrity Properly installed transition couplings maintain system pressure and prevent leaks, ensuring a safe and efficient flow of substances.

3. Versatility These couplings can be used in various applications, making them a useful solution for multi-material installations.

4. Reduced Maintenance The durable nature of effective transition couplings means fewer repairs and replacements over time.

Best Practices in Installation

To ensure optimal performance, the installation of HDPE to steel transition couplings should follow best practices

- Ensure Proper Alignment Misalignment during installation can introduce stress and lead to premature failure. - Follow Manufacturer Guidelines Adhering to installation instructions from the coupling manufacturer helps avoid compatibility issues.

- Inspect Regularly Routine inspections can help detect potential leaks or weaknesses in the system, ensuring long-term reliability.

Conclusion

In conclusion, HDPE to steel transition couplings are an integral component of modern piping systems, offering a reliable solution for connecting different materials. With careful design, proper installation, and adherence to best practices, these couplings provide the durability and efficiency necessary for a wide range of applications, contributing to the overall integrity and longevity of piping infrastructures. As industries increasingly adopt diverse materials for optimal performance, the importance of such couplings will only continue to grow.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025