Nov . 27, 2024 02:11 Back to list

HDPE to Steel Transition Coupling Manufacturing Options and Considerations for Project Development

Understanding HDPE to Steel Transition Coupling Factories

In today's engineering landscape, the need for effective piping systems is paramount. A critical component in this realm is the transition coupling, which facilitates the connection between different pipe materials. One of the most common transitions encountered is between High-Density Polyethylene (HDPE) and Steel. This article delves into the significance of HDPE to steel transition coupling factories, their production processes, and applications.

The Significance of HDPE and Steel

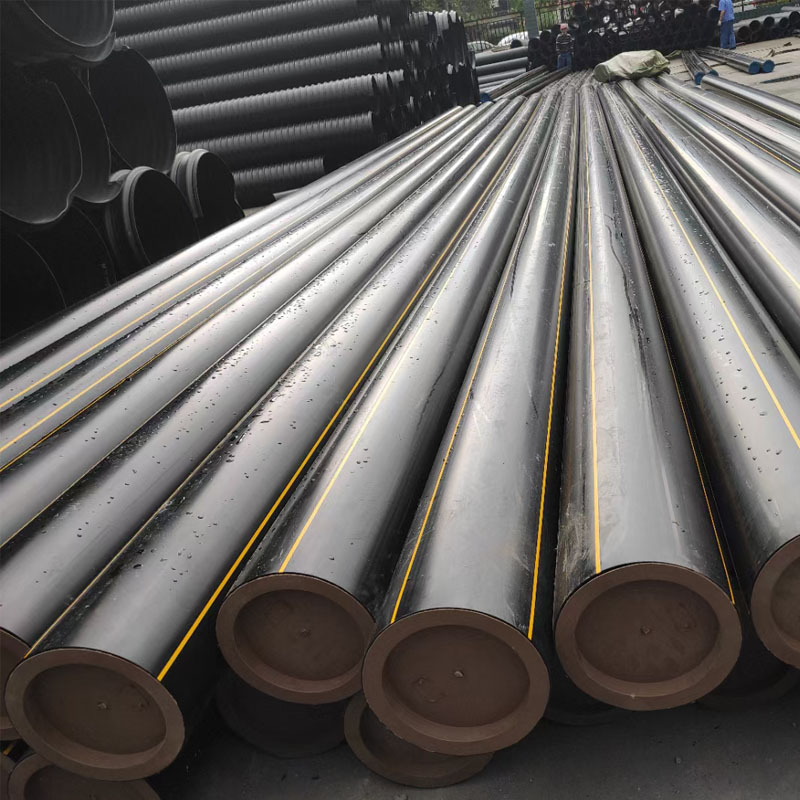

High-Density Polyethylene (HDPE) is a robust, lightweight thermoplastic known for its high strength-to-density ratio. It is widely used in various applications, including water and gas distribution pipes, due to its chemical resistance, durability, and low friction. Steel, on the other hand, is renowned for its strength and longevity, making it an ideal choice for structural applications and underground piping systems.

Transition couplings are necessary when connecting these two dissimilar materials, as they require specific engineering to ensure leak-proof, durable connections. The transition from HDPE to steel is particularly relevant in circumstances where plastic pipes must connect to existing steel infrastructure or in situations where steel pipes are used for high-pressure applications.

The Role of Transition Coupling Factories

Transition coupling factories specialize in manufacturing these critical components. The production process typically involves the following steps

1. Material Selection Factories must choose the right types of HDPE and steel that will ensure compatibility, durability, and resistance to environmental factors. High-quality materials are essential, as they directly influence the performance of the coupling under various conditions.

2. Design and Engineering Engineers design the couplings to meet specific industry standards and application requirements. This process often involves creating prototypes and conducting simulations to test the durability and performance of different designs.

3. Manufacturing Factories use advanced manufacturing techniques such as injection molding for HDPE components and machining for steel parts. Automated processes are often employed to enhance precision and efficiency. Quality control is critical during this phase, ensuring that the couplings meet all specifications.

hdpe to steel transition coupling factories

4. Testing After manufacturing, coupling assemblies undergo rigorous testing to assess their strength, flexibility, and resistance to pressure. This testing ensures that each unit can withstand the operational demands it will face in the field.

5. Distribution Once produced and tested, the transition couplings are packaged and distributed to various industries, including construction, municipal water systems, and oil and gas sectors.

Applications of HDPE to Steel Transition Couplings

HDPE to steel transition couplings are versatile and find applications in several fields

- Water Supply Networks These couplings are essential in municipal water systems where HDPE piping needs to connect with legacy steel infrastructure. The transition couplings enable seamless integration, ensuring a consistent flow of water.

- Gas Distribution In the natural gas sector, transitioning from steel pipelines to HDPE can reduce weight and improve flexibility, particularly in challenging terrains. Transition couplings facilitate safe and effective connections, adhering to strict safety standards.

- Industrial Applications Many industries utilize a combination of HDPE and steel in their systems. From chemical processing plants to oil refineries, the need for reliable and durable connections is critical for operational efficiency.

Conclusion

As industries continue to evolve, the demand for effective and reliable piping systems is greater than ever. HDPE to steel transition coupling factories play a crucial role in manufacturing the components needed for these systems. By using advanced technologies and high-quality materials, these factories contribute to the safety and efficiency of water and gas distribution systems across various sectors. Furthermore, as environmental consciousness rises, the versatility of HDPE paired with the strength of steel offers a sustainable solution for modern piping challenges. Understanding the significance of these factories and their products is essential for engineers and project managers aiming for efficient and durable installations.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025