Dec . 02, 2024 07:06 Back to list

HDPE to Steel Pipe Connection Manufacturing Solutions for Enhanced Infrastructure Durability and Performance

HDPE to Steel Pipe Connection Factories Bridging Two Essential Materials

In the modern industrial landscape, the efficiency and reliability of piping systems are paramount. Industries ranging from water treatment to oil and gas extraction require robust connections that can ensure durability and performance. High-Density Polyethylene (HDPE) and steel are two materials commonly used in piping systems, each with its own unique advantages. However, connecting these two materials presents specific challenges that specialized factories tackle through innovative engineering and expertise.

Understanding HDPE and Steel Pipes

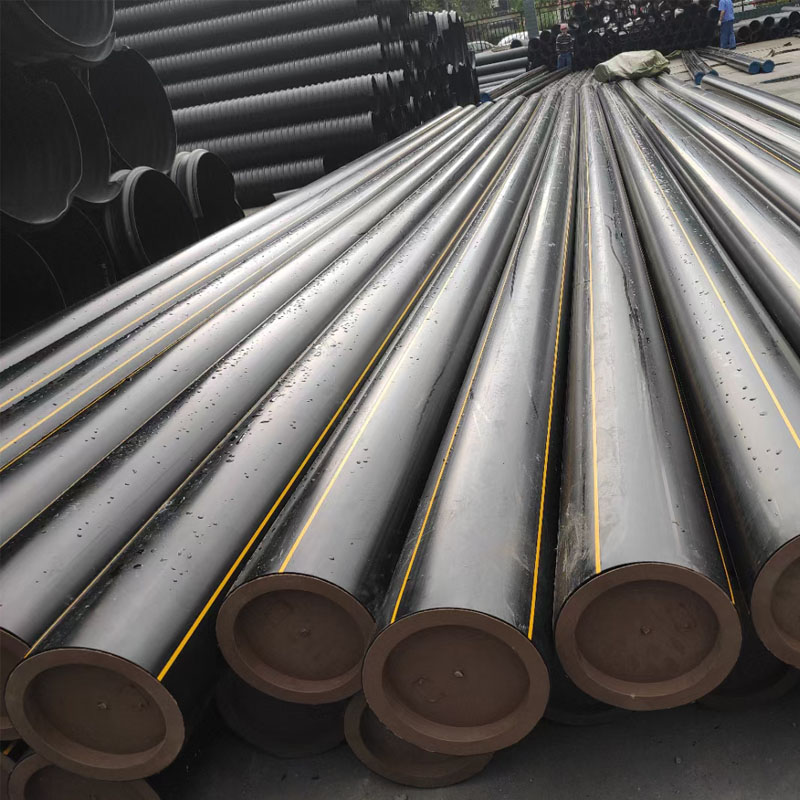

HDPE pipes are known for their flexibility, corrosion resistance, and lightweight characteristics, making them an ideal choice for a wide array of applications. They are particularly favored in agricultural, municipal, and industrial systems due to their ability to withstand a variety of environmental factors. On the other hand, steel pipes, renowned for their strength and durability, are often utilized in high-pressure and high-temperature applications, making them indispensable in sectors like oil and gas.

The Importance of Connection

While HDPE and steel pipes serve distinct purposes, there are situations where a connection between the two is necessary. For example, in a water distribution system that transitions from an underground network (often using HDPE due to its flexibility and low friction properties) to above-ground infrastructures or industrial systems that may use steel for structural integrity. The coupling of HDPE to steel requires specialized fittings and techniques to ensure leak-proof and long-lasting transitions.

Manufacturing Connections The Role of Factories

Specialized factories that focus on the connection of HDPE to steel pipes are critical to the industry. These facilities incorporate advanced technologies and skilled craftsmanship to produce fittings and connectors designed to handle the unique challenges posed by this hybrid connection.

hdpe to steel pipe connection factories

1. Engineering Innovations Factories employ engineering teams dedicated to designing connectors that can accommodate the differences in thermal expansion, flexibility, and pressure ratings between HDPE and steel. Custom solutions are often required to meet specific project needs, ensuring that the fittings can withstand environmental stresses while maintaining integrity.

2. Material Compatibility Understanding the chemical properties of both materials is essential. Factories utilize high-quality materials that ensure compatibility between HDPE and steel, helping prevent issues such as galvanic corrosion, which can occur when dissimilar metals are in contact.

3. Manufacturing Techniques Various techniques are employed in manufacturing connections, including welding, mechanical fittings, and elastomeric sealing systems. Each method serves a purpose and is selected based on the requirements of the application, such as pressure ratings and the potential for ground movement.

4. Quality Control Rigorous quality control measures are implemented to ensure that each product meets industry standards. This includes testing for leak resistance, pressure endurance, and overall durability. Many factories also invest in certifications from recognized bodies that validate their products for use in critical applications.

5. Sustainable Practices As industries move towards more sustainable practices, factories are increasingly focused on minimizing waste and using recyclable materials. This not only benefits the environment but also helps in catering to clients who prioritize sustainability in their operations.

Conclusion

Factories specializing in the connection of HDPE to steel pipes play a crucial role in ensuring the effectiveness and reliability of piping systems across various industries. As the demand for these connections grows, driven by the need for efficient infrastructure, advancements in manufacturing techniques and materials will continue to evolve. The marriage of HDPE and steel within these specialized factories not only enhances operational capabilities but also contributes to the development of safer and more sustainable industrial practices. The future of fluid transport significantly depends on the innovations bred within these essential manufacturing facilities, highlighting the importance of their work in building resilient infrastructures that can withstand the test of time.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025