Nov . 09, 2024 15:34 Back to list

Transition Coupling Solutions for HDPE to PVC Pipe Connections in Various Applications

Understanding HDPE to PVC Transition Couplings A Comprehensive Overview

In the world of piping systems, versatility and adaptability are essential for the smooth flow of fluids across different environments. One critical aspect of this flexibility comes from the relationships between various types of pipes, particularly when transitioning from High-Density Polyethylene (HDPE) to Polyvinyl Chloride (PVC). The HDPE to PVC transition coupling is a vital component in plumbing and industrial applications, enabling the seamless connection of two different piping materials. This article will delve into the importance, application, and installation of HDPE to PVC transition couplings.

Importance of Transition Couplings

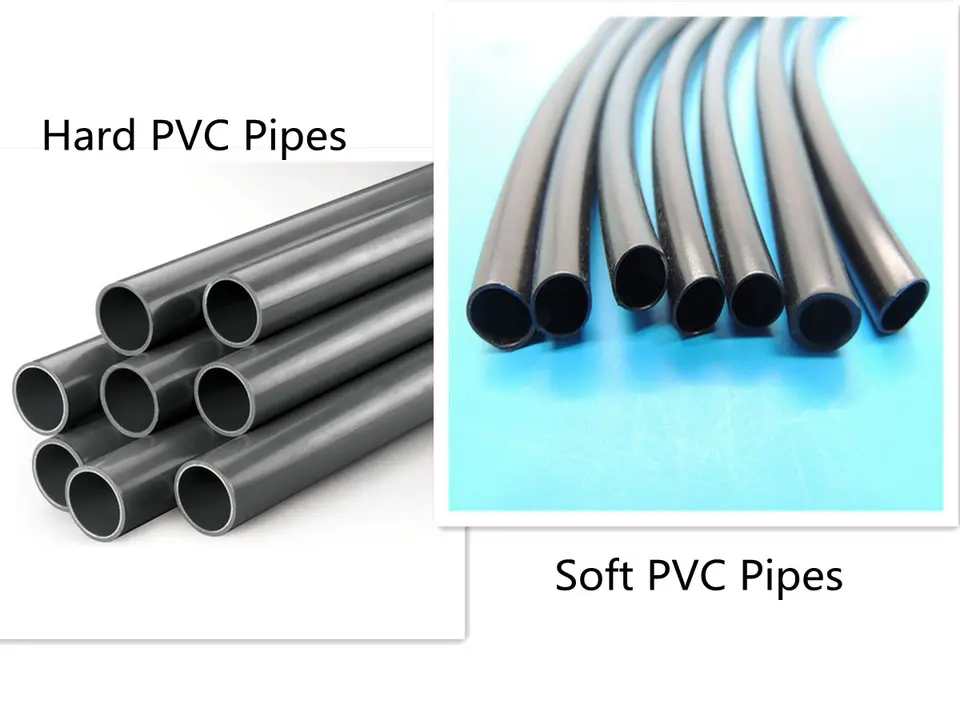

HDPE and PVC are some of the most commonly used materials in plumbing and drainage systems. HDPE is known for its high strength-to-density ratio, flexibility, and resistance to impact and chemicals. In contrast, PVC is celebrated for its durability, low cost, and excellent resistance to corrosion. These distinct properties make each material suited for specific applications. However, there are instances where a project requires the combination of both materials, whether due to availability, cost considerations, or specific project requirements. Transition couplings facilitate this combination by providing a reliable and leak-proof joint between the two different piping systems.

Applications of HDPE to PVC Transition Couplings

Transition couplings are widely used in various applications, including

1. Water Supply Systems Municipal water systems often require a mix of different piping materials. Transition couplings allow for the integration of HDPE and PVC pipes to transport drinking water safely and efficiently.

2. Sewer and Drainage Systems In sewer applications, pipes may need to switch from HDPE to PVC due to material strength requirements or local regulations. Transition couplings ensure that these junctions remain watertight.

3. Industrial Applications Many industrial processes involve chemical storage and transport, where HDPE and PVC might both be ideal choices. Transition couplings help in connecting the systems without compromising safety and structural integrity.

4. Irrigation Systems In agricultural settings, switching between HDPE and PVC can occur frequently as farmers adapt their systems to seasonal needs. Couplings enable these adjustments without hassle.

hdpe to pvc transition coupling service

Installation Considerations

Installing an HDPE to PVC transition coupling requires careful attention to detail to ensure a proper and long-lasting connection. Here are some essential steps and considerations for the installation process

1. Preparation Before starting, it is crucial to prepare both ends of the pipes involved. Ensure that the surfaces are clean and free from debris or contaminants to avoid compromising the seal.

2. Compatibility Verify that the transition coupling is rated for the specific diameters and pressure ratings of both the HDPE and PVC pipes being connected. Using the wrong size can lead to failures or leaks.

3. Heating (if applicable) For some couplings, especially those using fusion methods for HDPE, heating elements may be needed to ensure a proper bond. Always follow the manufacturer's instructions regarding temperatures and timing.

4. Secure Attachment Ensure that the coupling is securely fastened, whether through mechanical means like clamps or through fusion processes. A loose connection can lead to leaks and system failures.

5. Testing After installation, pressure testing is recommended to ensure there are no leaks at the joints. This step is critical in preventing future water loss and damage.

Conclusion

The use of HDPE to PVC transition couplings is a practical solution that allows for the effective integration of two different piping systems. Given the unique properties of each material, these couplings enable versatility in plumbing and industrial applications. Whether for municipal water supply, sewage systems, or irrigation, understanding and properly implementing these couplings ensures a safe, efficient, and reliable flow of fluids across piping infrastructures. As projects grow increasingly complex, mastery over the integration of diverse materials will play a crucial role in successful plumbing and industrial applications.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025