Sep . 23, 2024 18:42 Back to list

HDPE to PVC Pipe Couplings for Efficient Plumbing Solutions and Connections

Understanding HDPE to PVC Pipe Couplings

When it comes to plumbing and construction, the materials used for piping play a crucial role in ensuring durability, safety, and efficiency. High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are two of the most popular materials used in the industry due to their unique properties and advantages. However, when transitioning from HDPE to PVC or vice versa, a proper coupling is necessary to maintain the integrity of the piping system. This article explores the importance, functionality, and uses of HDPE to PVC pipe couplings.

What are HDPE and PVC?

HDPE is a type of plastic known for its high strength-to-density ratio. It is flexible, resistant to chemicals, and highly durable, making it an ideal material for various applications, including water supply, sewage systems, and more. PVC, on the other hand, is a rigid plastic that is exceptionally tough and resistant to environmental stressors. It is commonly used in building construction, piping, and electrical cable insulation due to its excellent durability and cost-effectiveness.

The Necessity of Couplings

When integrating HDPE and PVC pipes, couplings serve as essential connectors that provide a watertight seal and preserve the structural integrity of the piping system. Without proper coupling, the different thermal expansion rates and physical properties of HDPE and PVC could lead to leaks, material failure, or system inefficiencies.

Types of Couplings

There are several types of HDPE to PVC pipe couplings available on the market, including

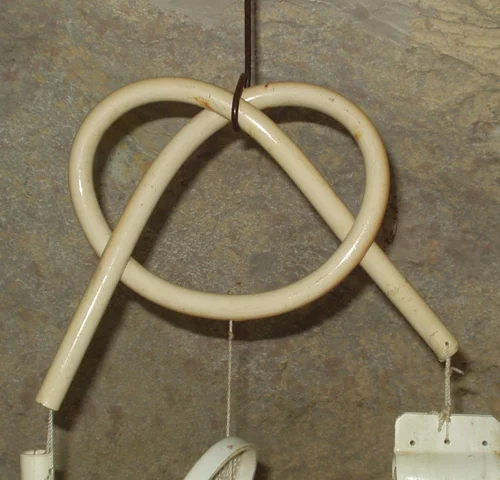

hdpe to pvc pipe coupling products

1. Mechanical Couplings These rely on clamps or mechanical fittings to join pipes together. They are easy to install and provide a strong connection without the need for heat or adhesives.

2. Flange Couplings Flanges can be attached to both HDPE and PVC pipes, allowing for easy disconnection and reconnection. This type of coupling is commonly used in systems requiring regular maintenance.

3. Fusion Couplings These involve the heating of the pipe ends to create a strong bond. While typically used for HDPE, specific fusion coupling products are designed to work with PVC as well.

4. Transition Fittings These fittings allow for a seamless transition from HDPE to PVC by accommodating the differing diameters and wall thicknesses.

Applications

HDPE to PVC pipe couplings are widely used in various sectors, including residential plumbing, agricultural irrigation, industrial applications, and municipal water systems. They are particularly beneficial in projects where different pipe materials must be joined without sacrificing performance.

Conclusion

In summary, HDPE to PVC pipe couplings are essential components in modern plumbing and construction projects. They facilitate the seamless integration of two different piping materials while ensuring the reliability and efficiency of the system. Whether for water supply, drainage, or irrigation, understanding how to utilize these couplings effectively can lead to optimal performance and longevity in piping systems. By selecting the appropriate coupling type and ensuring proper installation, contractors and homeowners can achieve superior results in their piping endeavors.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025