Oct . 22, 2024 10:23 Back to list

HDPE to PVC Coupling Solutions for Efficient Piping Systems and Installation Techniques

Understanding HDPE to PVC Coupling Services

In the realm of plumbing and piping systems, the need for efficient and reliable connections between different types of materials is paramount. High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are two of the most commonly used materials in various applications, from irrigation and drainage systems to municipal water supply lines and wastewater treatment facilities. To ensure seamless integration of these materials, HDPE to PVC coupling services have emerged as a critical aspect of modern piping infrastructure.

The Importance of HDPE and PVC

HDPE is renowned for its durability, flexibility, and resistance to chemicals and UV radiation. It is often used in applications where high impact resistance and toughness are required. In contrast, PVC is widely favored for its rigidity, lightweight nature, and excellent corrosion resistance. Each material has unique properties that make it suitable for specific applications; however, the requirement often arises to connect these two types of piping systems due to varying project specifications or material availability.

Given the distinct characteristics of HDPE and PVC, it is essential to employ specialized coupling techniques to create a secure and leak-proof connection between the two. This necessity fosters the growth of professional coupling services that focus exclusively on the integration of HDPE and PVC piping systems.

Types of Coupling Services

There are various methods and technologies used in HDPE to PVC coupling services. The choice of method depends on the specific application, site conditions, and project requirements. Some common coupling methods include

1. Mechanical Couplings These involve the use of fitting systems that secure HDPE and PVC pipes together through mechanical means, often using bolts and flanges. Mechanical couplings are easy to install and allow for disassembly if necessary.

hdpe to pvc coupling service

2. Heat Fusion Although heat fusion primarily applies to HDPE, this technique can sometimes be adapted for direct connection to PVC sources using transition fittings specially designed for this purpose. This results in a seamless, sturdy joint.

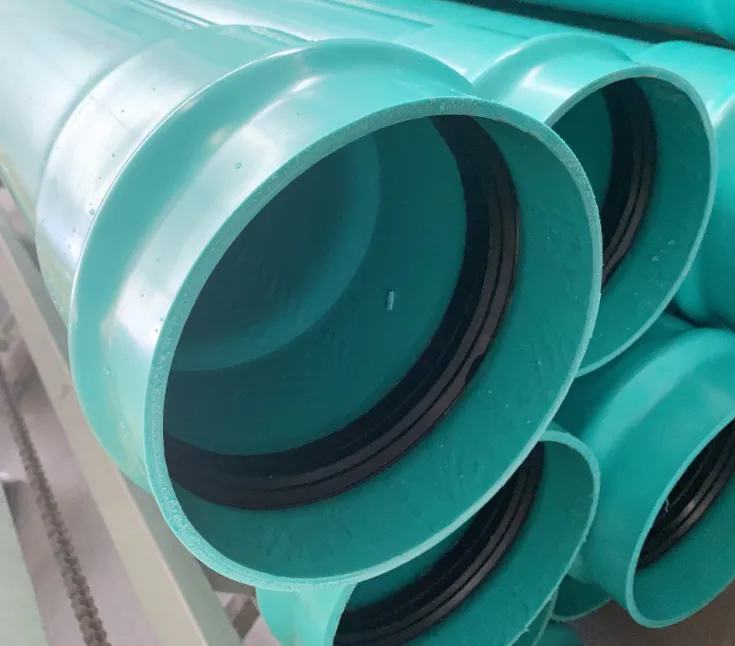

3. Gasketed Couplings This approach typically involves a rubber gasket that provides a tight seal between the HDPE and PVC. Gasketed couplings offer flexibility and ease of installation, making them a popular choice in various plumbing applications.

4. Solvent Cementing For smaller-diameter applications, solvent cement can be used to bond PVC to certain HDPE fittings. However, this requires a precise approach to ensure compatibility and secure adhesion.

Benefits of Professional Coupling Services

Engaging professional HDPE to PVC coupling services offers a myriad of benefits. These services ensure that connections are performed correctly the first time, which reduces the risk of leaks or failures in the system. Trained professionals utilize the right tools and techniques, which can extend the lifespan of the piping infrastructure. Furthermore, they often conduct thorough inspections before and after installation, ensuring compliance with local regulations and industry standards.

Additionally, professional services can advise on the most suitable coupling method for specific applications, which can enhance overall system efficiency and cost-effectiveness. Custom solutions tailored to the needs of the project can often lead to better performance and reduced long-term maintenance.

Conclusion

In summary, the integration of HDPE and PVC piping systems is an essential aspect of modern infrastructure. Utilizing specialized HDPE to PVC coupling services is critical for creating robust, leak-proof connections that stand the test of time. By relying on professional expertise, project managers can ensure that they meet their operational requirements while optimizing efficiency and durability. As industries continue to evolve, the importance of reliable coupling solutions will only grow, paving the way for innovative advancements in piping technology.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025