Dec . 03, 2024 14:56 Back to list

hdpe to pvc coupling factories

The Importance of HDPE to PVC Coupling Factories

In the vast world of manufacturing, the coupling of materials plays a critical role in various sectors, particularly in plumbing, construction, and industrial applications. One of the most crucial combinations in this arena is the coupling of High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC). This harmonious pairing not only ensures efficient flow and connectivity in piping systems but also delivers durability and resistance to environmental factors. As a result, the production of HDPE to PVC couplings has become a significant focus for many factories around the globe.

Understanding HDPE and PVC

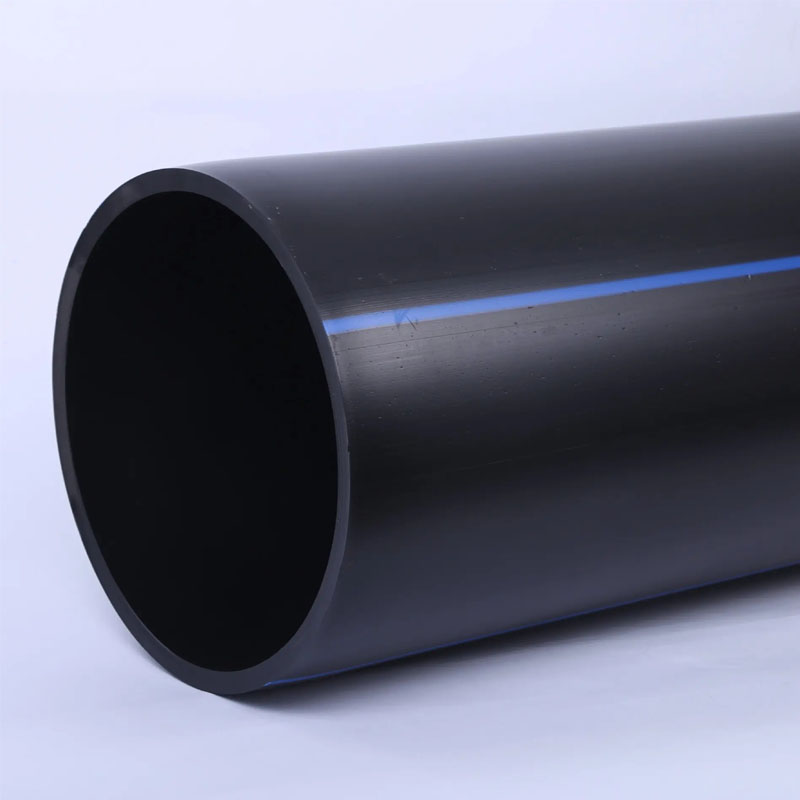

Before delving into the factories that produce HDPE to PVC couplings, it's essential to understand the properties of these materials. HDPE is a lightweight, high-strength plastic known for its resistance to impact, chemicals, and moisture. It is commonly used in applications that require excellent durability, such as water pipes, plastic bottles, and geomembranes. On the other hand, PVC is one of the most widely used plastics worldwide, featuring high tensile strength, resistance to corrosion, and excellent electrical insulation properties. It is extensively utilized in the manufacturing of pipes, fittings, and other construction materials.

The coupling of these two materials allows for the creation of versatile, high-performance products that can withstand various environmental stressors. Factories specializing in HDPE to PVC couplings bring together the best attributes of both materials, resulting in products that meet strict industry standards.

The Manufacturing Process

The manufacturing process of HDPE to PVC couplings involves several steps to ensure high-quality outputs. The first stage is the material preparation, where HDPE and PVC are sourced from reliable suppliers. Quality control tests are performed on these materials to verify their suitability for production.

Once the materials have been approved, they undergo a molding process. For HDPE to PVC couplings, several methods can be employed, including extrusion and injection molding. These techniques allow for precise shaping and ensure that the finished products will fit seamlessly into existing piping systems.

After the initial shaping, coupling products are subjected to various tests, including pressure testing, to ensure their reliability under operational conditions. Factories use advanced technologies to ensure that the couplings adhere to industry specifications and can withstand the stresses they will encounter in the field.

hdpe to pvc coupling factories

Quality Control and Standards

Quality control is paramount in factories producing HDPE to PVC couplings. Strict adherence to international standards, such as ASTM and ISO certifications, ensures that the couplings are not only durable but also safe for use in residential and industrial applications. Regular audits and inspections help maintain high production standards and minimize defects.

Moreover, some factories adopt advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) to streamline the design and production processes. This technological integration allows for greater efficiency and accuracy, resulting in higher-quality products that can be produced in shorter timeframes.

Market Demand and Applications

The demand for HDPE to PVC couplings continues to grow due to several factors. The construction and plumbing industries are seeking materials that offer both reliability and cost-effectiveness. HDPE to PVC couplings are particularly favored due to their compatibility with different piping systems, ease of installation, and resistance to environmental factors.

These couplings are often used in various applications, ranging from municipal water supply systems to irrigation and drainage networks. Their adaptability makes them suitable for both residential projects and large-scale industrial installations.

Conclusion

The role of HDPE to PVC coupling factories is vital in meeting the demands of modern infrastructure and industrial applications. By combining the strengths of HDPE and PVC, these factories deliver products that ensure seamless connectivity and durability. As technology progresses and the market evolves, the importance of HDPE to PVC coupling factories will only continue to rise, underscoring the need for quality manufacturing in this essential industry.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025