Nov . 10, 2024 02:54 Back to list

Connections between HDPE and PVC in Factory Settings and Their Applications

The Connection Between HDPE and PVC A Comprehensive Overview

In the world of industrial materials, HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) are two of the most widely used plastics. With their unique characteristics and advantages, they play a crucial role in various applications including construction, plumbing, and packaging. However, when it comes to connections between these two materials, it's essential to understand their properties, advantages, and methodologies for connection to ensure seamless integration in various applications.

Understanding HDPE and PVC

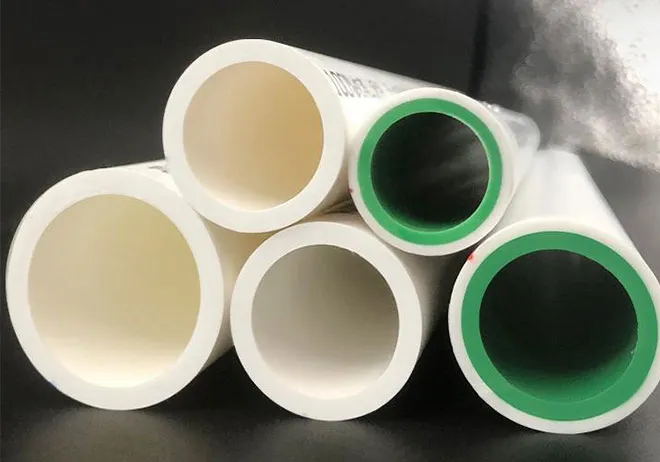

HDPE is a versatile polymer known for its high strength-to-density ratio. It possesses excellent resistance to impact, chemicals, and moisture, making it suitable for a wide range of applications. Common uses of HDPE include plastic bottles, piping, geomembranes, and plastic lumber. Its durability and resistance to environmental stressors make HDPE an ideal choice for long-term applications in harsh conditions.

PVC, on the other hand, is one of the most widely used synthetic plastic polymers in the world. PVC is highly versatile, available in both rigid and flexible forms. It is commonly used in building and construction for doors, windows, and plumbing systems. The rigid form of PVC possesses excellent structural integrity, while the flexible form carries excellent flexibility and adaptability, often used in electrical wiring and flooring.

The Need for Connection

Though HDPE and PVC have their distinct properties and applications, there are scenarios where they must be interconnected. For example, in plumbing systems, an HDPE pipe may need to connect to a PVC pipe. The ability to establish strong, leak-proof connections is crucial for the integrity of a plumbing system and overall safety.

Connection Methods

The connection methods between HDPE and PVC can vary, but several tried-and-true techniques are commonly employed

1. Mechanical Coupling This is one of the most straightforward methods for connecting HDPE to PVC. It involves the use of mechanical fittings that join the two pipes together. These fittings often include adapters with flanges or threaded ends that can accommodate each material’s unique dimensions.

hdpe to pvc connection factories

2. Fusion Welding While HDPE is known for its excellent welding capabilities, connecting it to PVC through fusion methods can be challenging due to the differences in their melting points and chemical properties. However, specialized fusion techniques can be employed when necessary. It's essential to consult with professionals who have experience with both types of materials for successful results.

3. Transition Fittings Many manufacturers produce transition fittings specifically designed to connect HDPE and PVC. These fittings provide a reliable solution for interconnectivity between the two materials, often featuring a combination of slip fittings and threaded ends to ensure a secure connection.

4. Adhesive Bonding In some cases, adhesives can be used to bond HDPE and PVC; however, this method is often less reliable compared to mechanical methods. Suitable adhesives must be chosen very carefully, considering the specific applications and environmental conditions they will be subjected to.

5. Sealants To enhance the integrity of the connection, sealants may be used in conjunction with mechanical coupling or adhesive bonding. Sealants provide additional protection against leaks, especially in high-pressure applications.

Advantages and Considerations

When establishing connections between HDPE and PVC, several advantages and considerations come into play. A notable advantage is the ability to harness the strengths of both materials. HDPE’s superior impact resistance and flexibility combined with PVC’s structural integrity can enhance the overall performance of a system.

However, there are challenges, too; for example, ensuring that the connection is leak-proof and able to withstand pressure variations common in plumbing systems is crucial. It is also vital to account for the thermal expansion and contraction of both materials, which can lead to issues if not properly managed.

Conclusion

In conclusion, the connection between HDPE and PVC is a vital aspect of modern plumbing and construction projects. Understanding the characteristics of both materials and employing suitable connection methods will lead to successful outcomes in various applications. As industries continue to evolve, ongoing research and innovation promise to enhance the interactions between these two versatile materials, paving the way for more efficient and durable plumbing solutions. Adopting the right techniques ensures stability, efficiency, and longevity in applications that utilize both HDPE and PVC.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025