Oct . 07, 2024 15:26 Back to list

hdpe straight coupler factory

The Importance of HDPE Straight Couplers in Modern Manufacturing

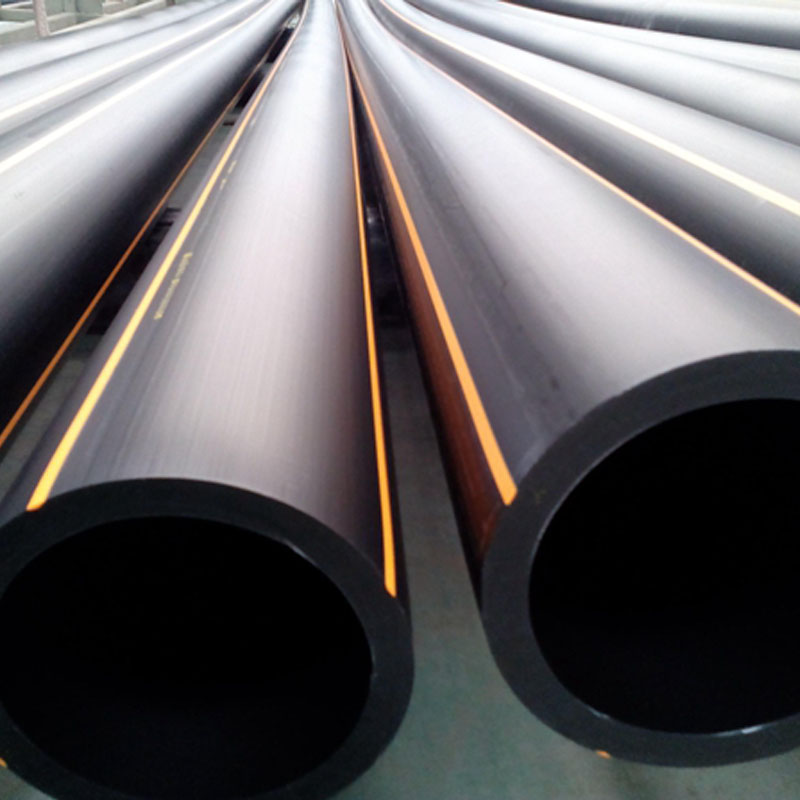

High-Density Polyethylene (HDPE) straight couplers are essential components in various industrial applications, particularly in fluid transportation systems. As factories strive to improve efficiency and reduce operational costs, the demand for reliable fittings has significantly increased. This article explores the importance of HDPE straight couplers and how factories are optimizing their use.

The Importance of HDPE Straight Couplers in Modern Manufacturing

One of the key advantages of HDPE straight couplers is their ease of installation. Unlike traditional metal fittings that require welding or threading, HDPE couplers can be easily fused, which not only speeds up the installation process but also minimizes labor costs. This ease of use makes them particularly appealing to factories that prioritize efficiency and cost-effectiveness.

hdpe straight coupler factory

Moreover, HDPE straight couplers are designed to withstand high pressures and temperatures, making them suitable for demanding applications. They provide an effective solution for transporting water, chemicals, and even sewage without the risk of degradation over time. This durability not only extends the lifespan of the piping systems but also reduces the frequency of replacements and repairs, leading to significant savings for factories in the long run.

In addition to their practical benefits, HDPE couplers are also environmentally friendly. HDPE is recyclable and contributes to sustainable practices in manufacturing. Factories that incorporate HDPE components into their systems are not only improving their operational efficiency but also aligning themselves with environmental standards, which can enhance their brand image and appeal to eco-conscious customers.

As the market for HDPE products continues to grow, factories are increasingly focusing on sourcing couplers from reputable manufacturers. Selecting high-quality HDPE straight couplers is crucial to ensuring the integrity of the entire piping system. Factory managers are advised to evaluate suppliers based on their manufacturing processes, quality control practices, and customer reviews to ensure they are investing in reliable products.

In conclusion, HDPE straight couplers play a pivotal role in modern manufacturing by enhancing efficiency, reducing costs, and promoting sustainability. Factories that recognize the value of these components will be well-positioned to thrive in an increasingly competitive market. By investing in high-quality HDPE fittings, manufacturers can ensure the longevity and reliability of their piping systems, ultimately contributing to their overall success and sustainability goals.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025