Jan . 13, 2025 17:55 Back to list

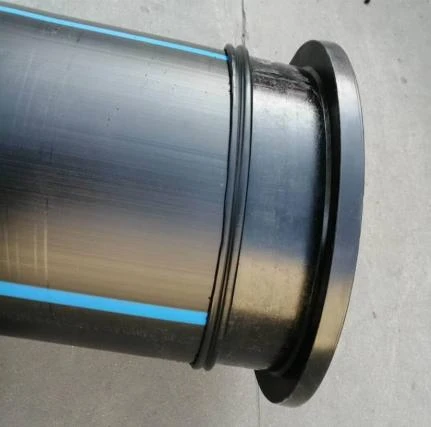

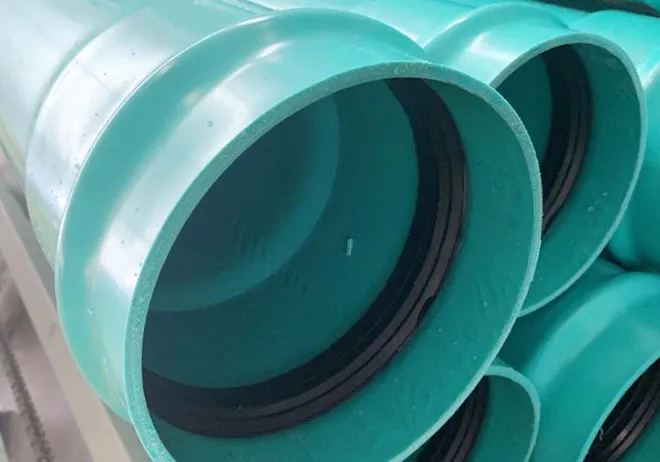

hdpe sprinkler pipe manufacturers

Furthermore, logistical efficiency in distribution and delivery impacts the price list of HDPE pipes. China's strategic positioning as a central hub for trade means that manufacturers can leverage robust logistics networks to reduce shipping costs, making HDPE pipes more competitively priced for both domestic and international markets. When evaluating the price list of HDPE pipes for water supply, it's vital to consider the long-term benefits they offer. HDPE pipes are resistant to corrosion, have a high tolerance for varying temperatures, and are less likely to crack or leak. These attributes translate into long-term savings on maintenance and replacement, offering excellent value for money, despite initial cost outlays. China's HDPE pipe industry benefits from a strong regulatory framework which enhances authoritativeness and credibility. Products are rigorously tested for performance and compliance, ensuring they meet the stringent standards required for water supply systems. This adherence to quality standards is a testament to the reliability and durability of the pipes, instilling confidence among buyers. In conclusion, the price list of China’s HDPE pipes for water supply systems is influenced by raw material costs, manufacturing advancements, quality assurance, and logistics. For industry professionals and project managers, considering these factors not only aids in making informed purchasing decisions but also ensures that installations remain sustainable and cost-effective over time. Given the significant advantages of HDPE pipes, they represent a wise investment in modern infrastructure, reflecting both innovation and economic foresight within China's manufacturing sectors.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025