Nov . 30, 2024 18:47 Back to list

Factories Producing HDPE Sprinkler Couplers for Agricultural Irrigation Systems

Understanding HDPE Sprinkler Couplers A Dive into Factories and Applications

High-Density Polyethylene (HDPE) has become a crucial material in modern irrigation systems, particularly due to its durability, resilience, and adaptability. Among the various components that facilitate efficient irrigation, HDPE sprinkler couplers play a vital role. This article explores the significance of HDPE sprinkler couplers, their manufacturing processes, and the promising future of these essential components in irrigation systems.

What are HDPE Sprinkler Couplers?

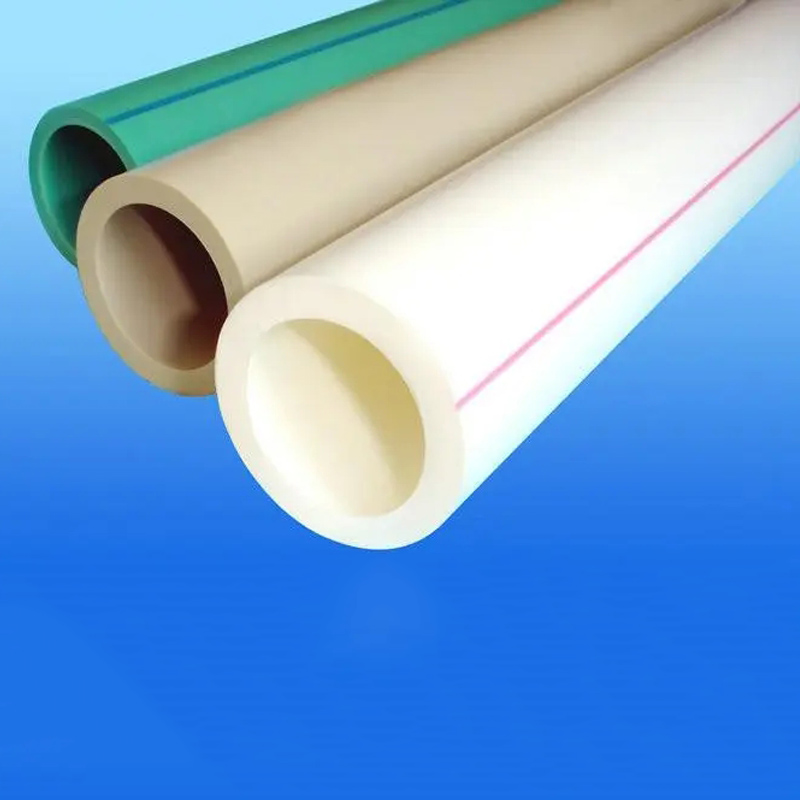

HDPE sprinkler couplers are fittings that connect different sections of HDPE pipes or hoses in irrigation setups. These couplers ensure a tight seal and provide flexibility in the system, allowing for easy adjustments and repairs. Their robust construction makes them suitable for a range of agricultural and landscaping applications, from small gardens to extensive agricultural fields.

The Importance of HDPE in Irrigation

The choice of HDPE as a material for sprinkler couplers stems from several inherent advantages. Firstly, HDPE is resistant to corrosion and chemicals, making it ideal for environments where fertilizers and pesticides are frequently used. Additionally, HDPE exhibits high impact resistance and can withstand varying temperatures, ensuring longevity and reliability in harsh conditions.

Furthermore, HDPE is lightweight, making it easy to install and handle. Its flexibility allows it to be bent and shaped without compromising its integrity, which is particularly advantageous in uneven terrains. These characteristics make HDPE sprinkler couplers an optimal choice for modern irrigation systems.

Manufacturing Processes of HDPE Sprinkler Couplers

The production of HDPE sprinkler couplers involves several critical steps. Factories typically begin by sourcing high-quality HDPE resin, which is then subjected to various processing techniques including extrusion, injection molding, or blow molding, depending on the design and specifications of the couplers.

hdpe sprinkler coupler factories

1. Extrusion This method involves melting the HDPE resin and forcing it through a die to create long sections of pipe, which can be cut into specified lengths for couplers.

2. Injection Molding For complex shapes and fittings, injection molding is often employed. In this process, the HDPE resin is heated and injected into a mold that reflects the desired shape of the coupler.

3. Blow Molding This technique is commonly used for creating hollow couplers. The molten HDPE is inflated into a mold to create the required shape, ensuring that the final product maintains a consistent wall thickness.

4. Quality Control Once the couplers are manufactured, they undergo rigorous testing to ensure they meet industry standards. This includes pressure testing, impact resistance evaluation, and checks for chemical resistance to guarantee durability and performance.

The Growing Market for HDPE Sprinkler Couplers

As water scarcity becomes a more pressing global issue, efficient irrigation methods are in high demand. The market for HDPE sprinkler couplers is expected to grow, driven by advancements in agricultural practices and an increasing focus on sustainable water management. Factories that specialize in these components are continuously innovating to develop more efficient and reliable products.

Additionally, the integration of smart technology in irrigation systems is creating opportunities for HDPE manufacturers. Smart sprinkler systems, which can be controlled remotely and programmed for optimal watering schedules, will likely rely heavily on high-quality HDPE components, including couplers.

Conclusion

HDPE sprinkler couplers are indispensable in modern irrigation systems, providing essential connections that ensure efficiency and reliability. With the increasing emphasis on sustainable agriculture and water conservation, the demand for HDPE products is set to rise. Factories that focus on the manufacturing of these couplers are poised to play a significant role in meeting the needs of this evolving market. As technology progresses and environmental considerations take center stage, HDPE sprinkler couplers will undoubtedly remain a critical element in the advancement of irrigation practices worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025