Oct . 09, 2024 16:59 Back to list

HDPE Pipe Applications and Benefits for Various Industries and Products

The Use of HDPE Pipe for Various Products

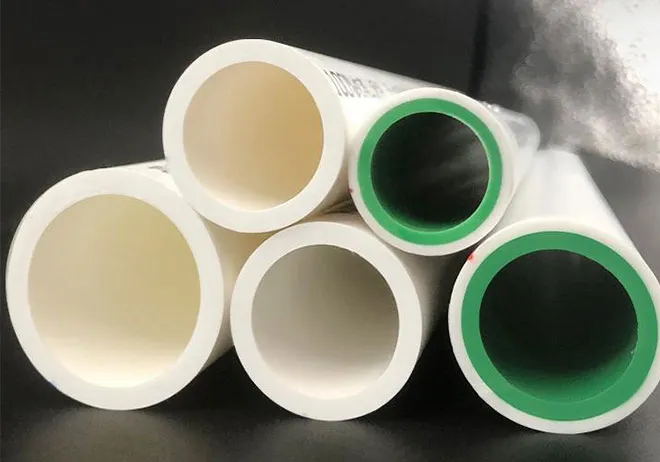

High-Density Polyethylene (HDPE) pipes are a prevalent choice in various industries due to their strength, flexibility, and resistance to chemical corrosion. HDPE is a thermoplastic polymer made from petroleum, which gives it remarkable durability and a long service life. The versatility of HDPE pipes makes them suitable for numerous applications, ranging from water supply systems to industrial drainage solutions.

The Use of HDPE Pipe for Various Products

In the agricultural sector, HDPE pipes are extensively employed for irrigation systems. Their lightweight nature makes them easy to handle and install, while their resistance to environmental stress cracking ensures longevity. Farmers often utilize HDPE for drip irrigation and sprinkler systems, as it helps in conserving water and delivering it efficiently to the crops. This contributes to sustainable agricultural practices, ultimately enhancing crop yields and conserving resources.

hdpe pipe used for product

HDPE pipes are also favored in the construction industry, where they are used for various plumbing and drainage systems. Due to their flexibility, these pipes can adapt to ground movement, reducing the risk of leaks and breakages. They are often utilized for stormwater management, as their smooth interior surfaces facilitate quick drainage, thereby minimizing the risk of flooding. Additionally, HDPE’s resistance to bacteria and fungi makes it a preferred choice for sewage and waste management systems.

In terms of environmental impact, HDPE pipes have distinct advantages. They are 100% recyclable, which helps reduce landfill waste and promotes a circular economy. Their production process consumes less energy compared to other pipe materials, such as PVC or metallic options, further decreasing their carbon footprint. Furthermore, HDPE’s longevity means that once installed, the need for replacement is significantly reduced, leading to less environmental disturbance over time.

Despite the multitude of benefits, it is crucial to recognize that the effective use of HDPE pipes necessitates proper installation and maintenance. Ensuring that joints and fittings are correctly connected is essential to prevent leaks and failures. Moreover, regular inspections can help in identifying potential issues before they escalate, ensuring a prolonged service life for the system.

In conclusion, HDPE pipes are vital in many applications, thanks to their durability, flexibility, and environmental benefits. From supplying clean water and managing wastewater to facilitating irrigation in agriculture, their diverse uses underscore their significance. As industries continue to seek sustainable and efficient solutions, HDPE pipes will undoubtedly play a crucial role in shaping the infrastructure of the future. Adopting these technologically advanced materials can lead not only to practical advantages but also to a more sustainable world.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025