Oct . 19, 2024 19:14 Back to list

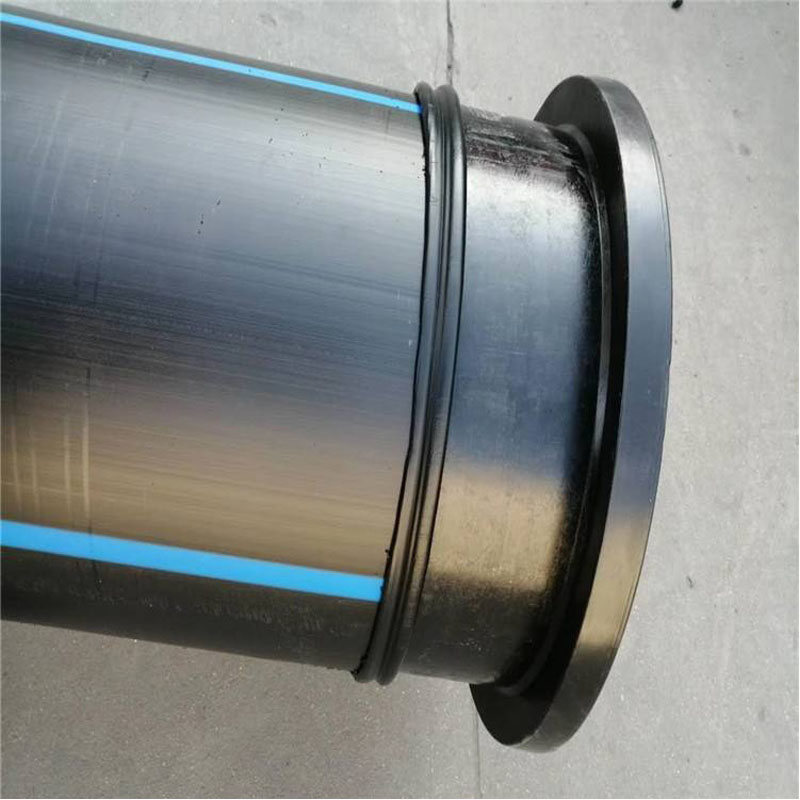

hdpe pipe used for manufacturer

The Importance of HDPE Pipe in Manufacturing

High-Density Polyethylene (HDPE) pipes have become a cornerstone for many industries, revolutionizing the way fluid and gas transportation is managed. With their remarkable properties and versatile applications, HDPE pipes are increasingly utilized in manufacturing processes across diverse sectors. Understanding the benefits and applications of HDPE pipes is crucial for manufacturers to optimize their operations and enhance productivity.

What is HDPE?

High-Density Polyethylene, or HDPE, is a thermoplastic polymer made from petroleum. Known for its high strength-to-density ratio, HDPE is a durable and flexible material. It is resistant to impact, chemicals, and corrosion, making it ideal for various applications. This unique combination of properties gives HDPE pipes a significant advantage over traditional materials such as metal and PVC.

Key Benefits of HDPE Pipes

1. Durability and Longevity HDPE pipes exhibit excellent durability, often lasting over 50 years with minimal maintenance. Their resistance to environmental stressors ensures they maintain structural integrity over time, making them a cost-effective long-term solution for manufacturers.

2. Corrosion Resistance Unlike metal pipes that can corrode and degrade when exposed to harsh chemicals or environmental conditions, HDPE pipes remain unaffected. This resistance to corrosion ensures that they can transport fluids safely without contamination, which is particularly critical in manufacturing processes involving chemicals.

3. Lightweight and Flexible HDPE pipes are significantly lighter than traditional piping materials, making them easier to handle and install. Their flexibility allows for easy bending and installation in various layouts, reducing the need for extensive fittings and joints that can be potential leak points.

4. Cost-Effectiveness The initial investment in HDPE pipes may be comparable to other materials. However, when considering their longevity, reduced maintenance costs, and the savings on installation due to their lightweight nature, HDPE pipes often result in lower overall costs for manufacturers.

hdpe pipe used for manufacturer

5. Eco-Friendly With growing concerns about the environment, manufacturers are increasingly turning to HDPE pipes as an eco-friendly option. They are recyclable and can be repurposed at the end of their life cycle, reducing waste and promoting sustainable manufacturing practices.

Applications in Manufacturing

HDPE pipes are utilized across various manufacturing sectors, including

- Water Supply and Drainage HDPE pipes serve as a reliable solution for transporting potable water and managing waste. Their ability to withstand pressure and resist corrosion makes them ideal for municipal water systems and industrial drainage.

- Chemical Processing In chemical manufacturing, HDPE pipes are commonly used to transport corrosive substances safely. Their resistance to chemicals ensures that they can handle a wide range of materials without degrading.

- Oil and Gas Industry The oil and gas sector uses HDPE pipes for transporting hydrocarbons and other fluids due to their strength and resistance to environmental stressors. They are often used in hydrocarbon extraction and transportation.

- Telecommunications HDPE pipes are also employed in telecommunications for protecting cabling. Their lightweight and flexible properties allow for easy installation and routing of cables, shielding them from external elements.

Conclusion

In conclusion, HDPE pipes have proven to be an invaluable asset in modern manufacturing. Their durability, resistance to corrosion, cost-effectiveness, and eco-friendliness make them a preferred choice across various industries. As manufacturing continues to evolve, embracing innovative materials like HDPE will be essential for improving efficiency, reducing costs, and promoting sustainability. For manufacturers looking to enhance their operations, investing in HDPE pipe technology could undoubtedly pave the way for a more resilient and efficient future.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025