Nov . 04, 2024 20:02 Back to list

hdpe pipe size chart service

Understanding HDPE Pipe Size Chart A Comprehensive Guide

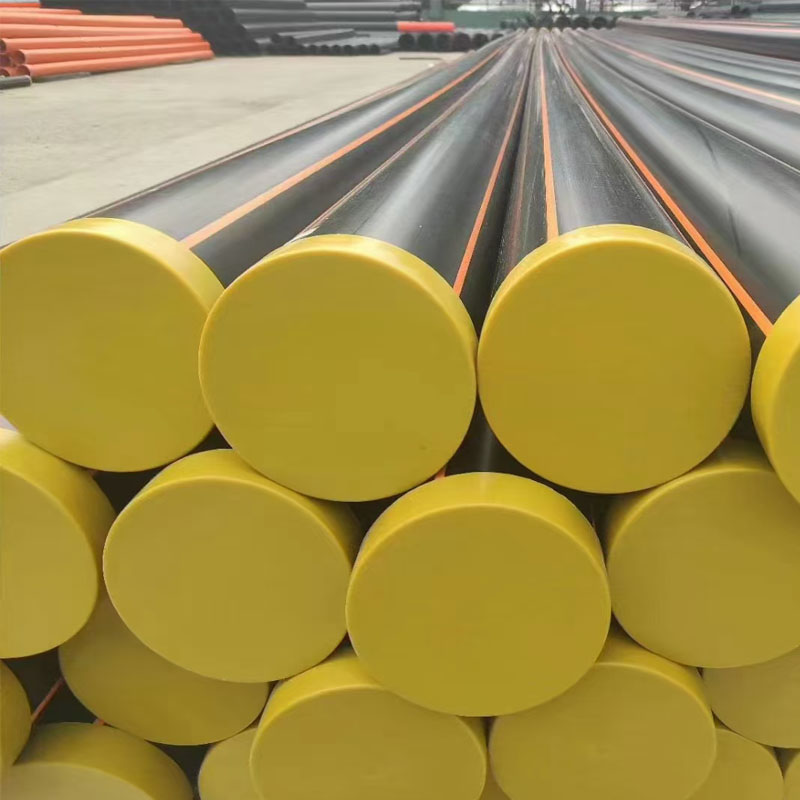

High-Density Polyethylene (HDPE) pipes have gained immense popularity in various industries due to their durability, lightweight nature, and resistance to corrosion and chemical factors. A critical aspect of working with HDPE pipes is understanding their sizing, which can significantly impact the efficiency and effectiveness of a project. In this article, we will delve into the HDPE pipe size chart, its significance, and how to effectively use it.

What is HDPE?

HDPE is a thermoplastic polymer made from petroleum. This material is characterized by its high strength-to-density ratio, making it ideal for applications that require robust performance in challenging conditions. Commonly used for water and gas distribution, mining, sewage and drainage, agricultural irrigation, and industrial applications, HDPE pipes are known for their longevity and flexibility.

Importance of Pipe Sizing

The size of HDPE pipes is crucial as it dictates the flow capacity, pressure rating, and the overall efficiency of any project involving fluid transfer. An appropriately sized pipe ensures that the system functions correctly without unnecessary pressure losses or flow restrictions. Miscalculating pipe sizes can lead to several issues, including increased operational costs, potential system failures, and reduced lifespans of the piping network.

Understanding the HDPE Pipe Size Chart

The HDPE pipe size chart plays a pivotal role in selecting the right pipe for your project. The chart typically includes several key parameters

1. Nominal Pipe Size (NPS) This is the standardized measurement for pipe sizes. For HDPE pipes, the nominal size does not always correspond to the actual diameter, making it essential to verify specifications.

2. Outside Diameter (OD) This measurement is critical for understanding the overall dimensions of the pipe. HDPE pipes are often available in various outside diameters to accommodate different applications.

hdpe pipe size chart service

3. Wall Thickness The wall thickness affects the pipe's pressure rating and its ability to withstand various external loads. Understanding the relationship between wall thickness and pressure is essential for ensuring the pipe will perform as required.

4. Pressure Rating This value indicates the maximum pressure the pipe can handle. It varies with different sizes and wall thicknesses, so selecting a pipe with an appropriate pressure rating is crucial for system safety and performance.

5. Length HDPE pipes come in various lengths, from standard 20-foot sections to custom lengths depending on project needs. Knowing the required pipe length helps in calculating the total number of pieces needed for assembly.

How to Use the HDPE Pipe Size Chart

1. Determine the Required Flow Rate Establish how much fluid needs to be transferred through the pipe per unit time. This measurement helps determine the necessary pipe diameter for optimal flow.

2. Select the Appropriate Pressure Rating Assess the system's operating pressure and choose an HDPE pipe that can safely handle the maximum pressure to avoid leaks or burst scenarios.

3. Consider Application-Specific Factors Different applications may require different wall thicknesses due to external loads, fluid types, or environmental conditions. Always refer back to the chart to ensure these factors are considered.

4. Consult with Professionals When in doubt, consulting with engineers or professionals in fluid dynamics can help ensure the correct pipe size is selected based on the specific application requirements.

Conclusion

Understanding the HDPE pipe size chart is vital for anyone involved in construction, plumbing, or any industry relying on efficient fluid transfer systems. By accurately interpreting the sizing chart and considering factors such as nominal size, outside diameter, wall thickness, and pressure ratings, project managers can ensure the success of their operations. Choosing the right HDPE pipes not only enhances system performance but also contributes to long-term sustainability and cost-efficiency.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025