Dec . 03, 2024 14:40 Back to list

HDPE Pipe Price List and Product Information PDF Guide

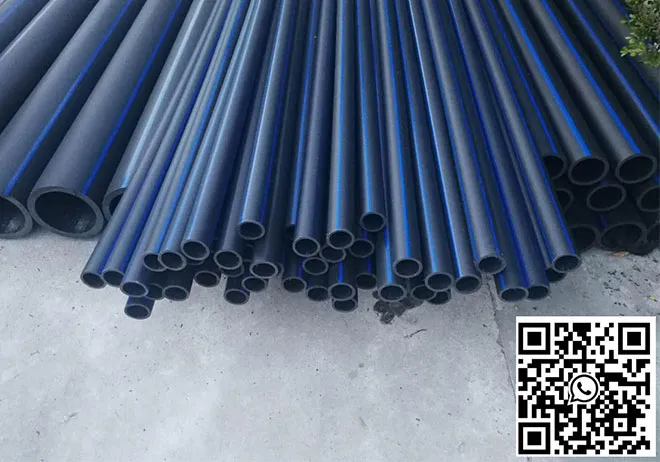

Understanding HDPE Pipe Pricing A Comprehensive Overview

High-Density Polyethylene (HDPE) pipes have gained significant popularity in various industries, particularly in water supply and drainage systems. Known for their high strength, flexibility, and resistance to corrosion, HDPE pipes are an excellent choice for numerous applications. However, the pricing of HDPE pipes can vary based on several factors, including material costs, manufacturing processes, supply and demand dynamics, and geographical location. This article aims to provide insights into the pricing trends and factors influencing the cost of HDPE pipes, often outlined in products like HDPE pipe price list PDFs.

Factors Influencing HDPE Pipe Prices

1. Material Costs The primary component of HDPE pipes is high-density polyethylene, a polymer derived from petroleum. Fluctuations in crude oil prices directly impact the cost of raw materials required for production. As oil prices rise, so too can the price of HDPE pipes. Additionally, the sourcing of quality resin contributes to price variability, with certain grades being more expensive due to their enhanced properties.

2. Manufacturing Processes The technology and methods used to manufacture HDPE pipes can affect their price. Pipes produced through advanced manufacturing processes may incur higher production costs, leading to increased prices. Furthermore, companies that invest in state-of-the-art machinery and technology to enhance efficiency and product quality may pass these costs onto consumers.

3. Pipe Specifications The specifications of HDPE pipes, such as diameter, wall thickness (pressure class), and the intended application, significantly influence pricing. Larger diameter pipes are typically more expensive due to the increased material usage and complexity of manufacturing. Additionally, pipes designed for high-pressure applications may require thicker walls, further increasing costs.

4. Market Demand and Competition The level of demand for HDPE pipes, influenced by construction projects, infrastructure development, and public utilities, plays a crucial role in pricing. During periods of high demand, prices may surge, particularly if supply is limited. Conversely, during economic downturns or periods of reduced construction activity, prices may decline as companies seek to sell excess inventory.

5. Geographical Location The location of both the manufacturer and the end-user can affect pricing due to transportation costs. Regions with limited access to manufacturing facilities might experience higher prices owing to shipping costs. Additionally, local regulations and tariffs can influence the final cost of HDPE pipes.

hdpe pipe price list pdf products

Understanding Price Lists

To navigate the often-complex landscape of HDPE pipe pricing, stakeholders benefit from comprehensive price lists that outline various products. HDPE pipe price lists, usually available in PDF format, provide critical information such as

- Product specifications (size, pressure ratings, etc.) - Unit costs, typically listed per linear foot or meter - Discounts for bulk purchases - Delivery charges and lead times - Manufacturer warranties and terms of sale

These price lists serve as an essential resource for contractors, engineers, and procurement officers when budgeting for projects and comparing suppliers.

Conclusion

In conclusion, understanding the pricing of HDPE pipes requires an appreciation of the multifaceted factors affecting costs. Prices can vary significantly based on material costs, manufacturing practices, pipe specifications, market dynamics, and geographic considerations. For anyone involved in purchasing or specifying HDPE pipes, keeping abreast of market trends and regularly consulting updated price lists is crucial for making informed decisions. Whether for a large-scale municipal project or residential plumbing, understanding how these factors interplay can lead to better cost management and ultimately, successful project outcomes.

As the demand for durable and efficient piping solutions continues to rise, awareness of pricing dynamics will only become more critical for professionals in the field. Ultimately, aligning the selection of HDPE pipes with budgetary constraints without compromising on quality will remain a fundamental goal for many in the industry.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025