Nov . 13, 2024 19:33 Back to list

hdpe pipe joint coupler service

Understanding HDPE Pipe Joint Couplers Importance and Applications

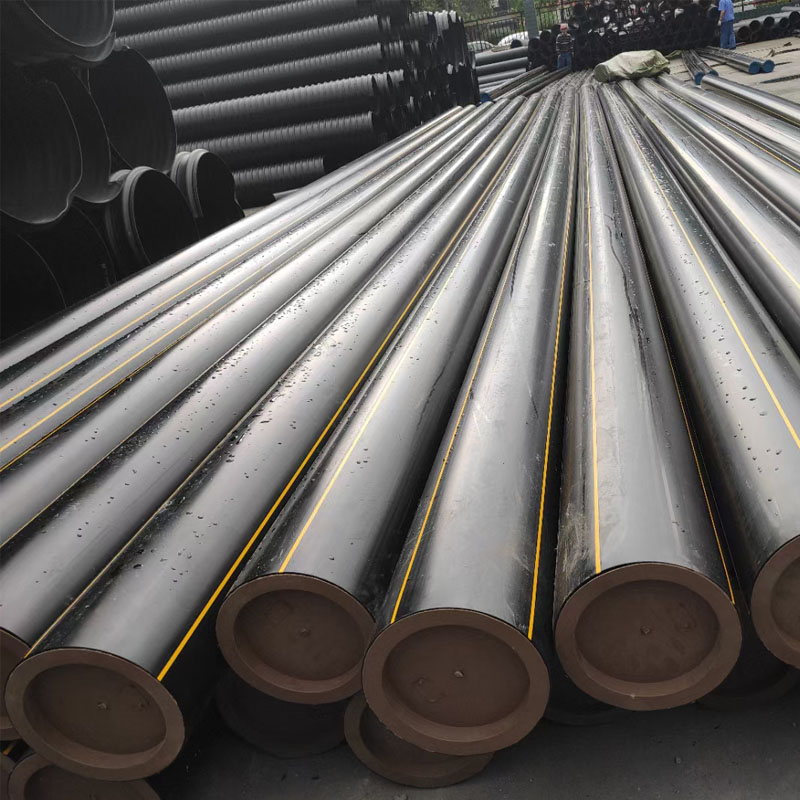

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, flexibility, and resistance to corrosive substances, making them an excellent choice for various applications, including water supply, sewage, and industrial projects. One of the critical components in the assembly of HDPE piping systems is the pipe joint coupler. This article aims to underscore the importance of HDPE pipe joint couplers and their roles in ensuring system integrity and efficiency.

What is an HDPE Pipe Joint Coupler?

An HDPE pipe joint coupler is a mechanical fitting used to connect two pipes together. It serves as an intermediary that allows for the extension or repair of piping systems. Couplers can vary in size, design, and functionality, tailored to meet specific installation requirements. They enable the seamless joining of pipes, which is crucial for maintaining the flow and pressure within the system.

Importance of HDPE Pipe Joint Couplers

1. Durability and Longevity HDPE couplers are designed to withstand harsh environmental conditions. They resist rust, corrosion, and chemical damage, ensuring that the joints remain intact for extended periods without the need for frequent maintenance or replacement.

hdpe pipe joint coupler service

2. Leak Prevention One of the primary concerns in any piping system is the risk of leaks. HDPE pipe joint couplers form tight seals that prevent water or other substances from escaping. This is particularly important in applications such as potable water supply, where leaks can lead to contamination or loss of resources.

3. Ease of Installation Couplers are generally easy to install, allowing for quick assembly and modifications to the piping system. This ease of use translates to reduced labor costs and shorter project timelines. Specialized tools are often unnecessary, making installation accessible even for those with limited experience.

4. Flexibility and Adaptability HDPE pipe joint couplers come in various designs to accommodate different pipe sizes and configurations. This adaptability makes them suitable for a wide range of applications, from residential plumbing to large-scale industrial systems.

5. Cost-Effectiveness By reducing the likelihood of leaks and system failures, HDPE couplers contribute to long-term cost savings. Their durability means fewer replacement costs and less downtime for repairs, allowing systems to run efficiently over time.

Conclusion

In summary, HDPE pipe joint couplers are integral to the functionality and reliability of HDPE piping systems. Their durability, ability to prevent leaks, ease of installation, adaptability, and cost-effectiveness make them a smart choice for any piping project. As industries continue to evolve and seek more efficient solutions, the role of HDPE pipe joint couplers will undoubtedly become even more critical in ensuring sustainable and effective piping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025