Nov . 05, 2024 04:14 Back to list

hdpe pipe joint coupler products

Understanding HDPE Pipe Joint Couplers Applications, Benefits, and Considerations

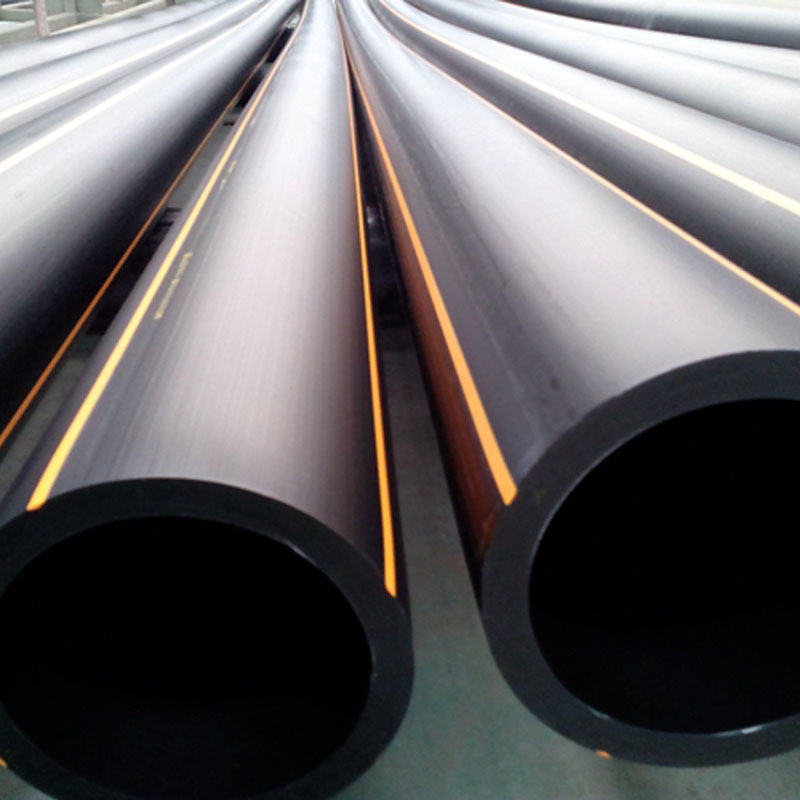

High-Density Polyethylene (HDPE) pipes have gained popularity in various applications due to their excellent durability, chemical resistance, and flexibility. An integral part of the HDPE piping system is the joint coupler, which plays a crucial role in establishing secure and efficient connections between pipes. This article will delve into the functions, benefits, and considerations of HDPE pipe joint couplers.

What are HDPE Pipe Joint Couplers?

HDPE pipe joint couplers are specialized fittings designed to connect two sections of HDPE pipes, enabling the seamless flow of fluids or gases. These couplers are essential for constructing pipelines used in agriculture, water distribution, sewage systems, and industrial applications. Joint couplers can come in various designs, such as socket fusion, electrofusion, or mechanical connections, each offering unique advantages depending on the specific requirements of the installation.

Types of HDPE Joint Couplers

1. Socket Fusion Couplers These are often used in smaller diameter pipes and involve heating the ends of the pipes and the coupler until they melt and fuse together. This method creates a strong, homogeneous joint that is resistant to leaks.

2. Electrofusion Couplers These couplers utilize an electric heating element to facilitate the melting of the pipe ends. The process is controlled and typically results in a joint with superior strength and reliability, making it suitable for larger diameter applications.

3. Mechanical Couplers These fittings use mechanical means to connect the pipes, usually with bolts or clamps. Mechanical couplers are advantageous because they allow for easy disassembly, making repairs and adjustments simpler compared to fusion-based methods.

Benefits of Using HDPE Joint Couplers

1. Durability and Longevity HDPE materials are resistant to corrosion, chemicals, and UV radiation, ensuring that the couplers maintain their structural integrity over time. This characteristic significantly reduces maintenance costs and extends the lifespan of the piping system.

hdpe pipe joint coupler products

3. Leak-Free Connections Proper installation of HDPE couplers creates a seamless joint that minimizes the risk of leaks. This is crucial in applications where leakage could lead to environmental concerns or financial losses.

4. Ease of Installation Many joint couplers, particularly mechanical types, can be installed quickly and require less specialized equipment compared to traditional piping materials. This can lead to reduced labor costs and faster project completion times.

5. Cost-Effectiveness While the initial investment might be higher compared to some traditional piping systems, the long-term savings from reduced maintenance and prolonged lifespan make HDPE piping with couplers a cost-effective choice.

Considerations When Choosing HDPE Joint Couplers

1. Diameter and Pressure Ratings Selecting the right coupler involves ensuring that it matches the diameter of the pipes and can withstand the pressure of the fluid being transported.

2. Installation Environment Factors such as temperature, soil conditions, and exposure to chemicals can affect the choice of couplers. It's important to assess these conditions to ensure compatibility.

3. Regulatory Compliance Ensure that the couplers meet local and international standards for safety and environmental protection, especially in applications involving drinking water or hazardous materials.

4. Maintenance Requirements While HDPE couplers are generally low-maintenance, understanding any specific care or inspection required can help maintain the system’s efficiency over time.

Conclusion

HDPE pipe joint couplers are essential components of modern piping systems, offering durability, flexibility, and leak-free connections. As industries continue to recognize the benefits of HDPE materials, the demand for reliable joint couplers will only grow. By selecting the right type of coupler and considering specific installation conditions, users can ensure the longevity and efficiency of their HDPE piping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025