Nov . 07, 2024 16:52 Back to list

HDPE Pipe Joint Coupler Manufacturers and Their Key Production Techniques

Exploring HDPE Pipe Joint Coupler Factories Innovations and Industry Insights

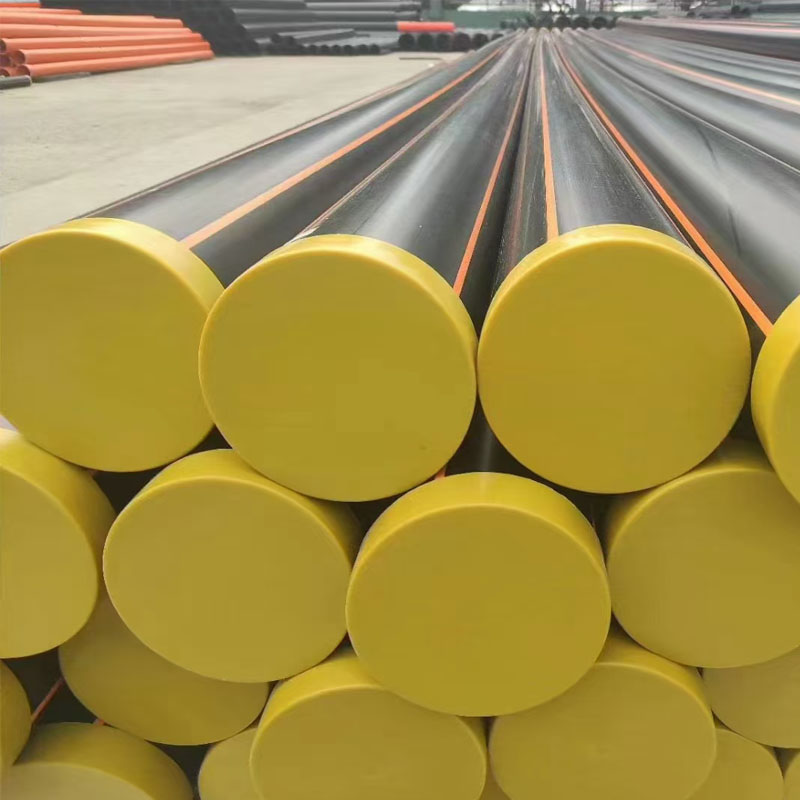

High-Density Polyethylene (HDPE) pipes have revolutionized the plumbing and construction industries due to their durability, flexibility, and resistance to corrosion. As a crucial component in various applications, HDPE pipe joint couplers play a significant role in ensuring seamless connections and long-lasting performance. This article delves into the fascinating world of HDPE pipe joint coupler factories, exploring their innovations, manufacturing processes, and contributions to the industry.

Understanding HDPE and Its Advantages

HDPE is a thermoplastic polymer known for its high strength-to-density ratio. It exhibits excellent resistance to impact, chemicals, and UV radiation, making it an ideal material for numerous applications, including water supply systems, gas distribution, sewage systems, and more. The importance of reliable joints in HDPE piping systems cannot be overstated. Joint couplers provide essential connectivity between pipe sections, ensuring the integrity and efficiency of the entire system.

Manufacturing Innovations in HDPE Joint Couplers

Manufacturers of HDPE pipe joint couplers are continually adopting innovative technologies to enhance product quality and reduce production costs. Advanced injection molding and extrusion techniques are commonly employed to create couplers that are robust yet lightweight. Utilizing computer-aided design (CAD) software allows for precise modeling, ensuring that every coupler meets stringent industry standards.

Moreover, automation in the manufacturing process has significantly improved efficiency. Automated systems can streamline production lines, minimize human error, and increase output. Additionally, factories are implementing quality control measures that include rigorous testing procedures to guarantee the performance and reliability of each coupler.

Sustainability in HDPE Coupler Production

Sustainability is a key focus for many HDPE pipe joint coupler factories. The production of HDPE products generally involves the use of recycled materials, contributing to a circular economy. Manufacturers are actively seeking ways to reduce waste during production and improve energy efficiency. By investing in eco-friendly technologies and processes, these factories are not only reducing their carbon footprint but also meeting the increasing demand for sustainable building materials.

hdpe pipe joint coupler factories

Furthermore, HDPE joint couplers themselves play a role in sustainability. Their durability means that they have a long lifespan, reducing the need for frequent replacements and minimizing environmental impact. As municipalities and industries worldwide shift towards sustainable practices, the demand for high-quality HDPE products continues to grow.

The Role of Quality Standards and Certifications

Quality assurance is vital in the manufacturing of HDPE pipe joint couplers. Factories are often certified by international standards such as ISO and ASTM, which dictate stringent guidelines for product performance, safety, and environmental impact. Adhering to these standards ensures that manufacturers deliver couplers that can withstand the rigors of diverse applications, from residential plumbing to complex industrial systems.

Industry certifications enhance consumer trust and pave the way for larger contracts, especially in critical infrastructure projects where reliability is paramount. Many manufacturers also engage in continuous research and development to meet evolving standards and to explore new materials and designs that can improve the performance of couplers further.

Market Trends and Future Prospects

The market for HDPE pipe joint couplers is witnessing significant growth, driven by increasing infrastructure development and rising awareness of the advantages associated with HDPE systems. As urbanization continues to expand, there is a burgeoning need for efficient water distribution and waste management systems, both of which rely on effective joint couplers.

Looking ahead, we can anticipate further innovations in the HDPE coupler production process, including the use of smart technologies like IoT for monitoring the performance and integrity of joints. Furthermore, as global demand for renewable energy sources grows, the adaptation of HDPE couplers for applications in solar and wind energy projects may offer exciting new opportunities for factories.

Conclusion

HDPE pipe joint coupler factories are pivotal in shaping the future of plumbing and construction industries. Their commitment to innovation, sustainability, and quality assurance positions them as key players in meeting the demands of modern infrastructure. As the landscape of building materials continues to evolve, the role of HDPE joint couplers will undoubtedly expand, offering solutions that are both reliable and environmentally responsible.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025