Dec . 12, 2024 10:09 Back to list

hdpe pipe for water supply specifications manufacturer

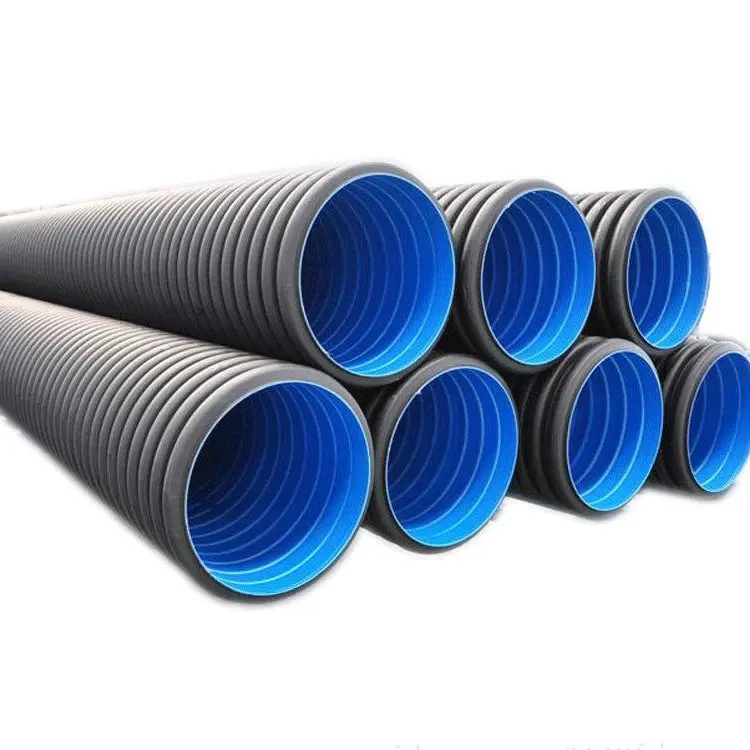

Understanding HDPE Pipe Specifications for Water Supply

High-Density Polyethylene (HDPE) pipes have become a popular choice in various water supply applications due to their durability, corrosion resistance, and versatility. HDPE pipes are manufactured according to strict specifications that ensure they meet the needs of modern water supply systems. In this article, we will explore the essential specifications for HDPE pipes, their benefits, and the factors to consider when selecting a manufacturer.

1. Material Composition

HDPE pipes are made from high-density polyethylene resin, with a density greater than 0.941 g/cm³. This material gives the pipes their strength and flexibility, making them suitable for a range of applications. The most common standards for HDPE pipes are governed by organizations such as the American Society for Testing and Materials (ASTM), the American Water Works Association (AWWA), and the International Organization for Standardization (ISO). Manufacturers must comply with these standards to ensure quality.

2. Pipe Dimensions and Thickness

HDPE pipes are available in various sizes, typically from 1 inch to 63 inches in diameter, allowing for flexibility in usage. The pipe wall thickness is determined by the Pipe Stiffness, which is crucial for withstanding external loads without deforming. The most commonly specified dimensions for HDPE pipes are defined by the Standard Dimension Ratio (SDR), which is a ratio of the pipe diameter to the wall thickness. Lower SDR values indicate thicker walls and better resistance to pressure — critical characteristics for water supply applications.

HDPE pipes are sorted based on their pressure ratings, which indicate the maximum pressure they can withstand during operation. The pressure ratings are often specified in terms of the Pressure Class (e.g., PE4710). For water supply applications, selecting a pipe with an appropriate pressure rating is essential. Common pressure ratings for HDPE pipes include 160 PSI, 200 PSI, and 250 PSI, ensuring they are fit for various operational conditions.

hdpe pipe for water supply specifications manufacturer

4. Temperature and Environmental Considerations

HDPE pipes are known for their ability to accommodate a wide range of temperatures, typically from -40°F to 140°F (-40°C to 60°C). However, extreme temperatures can affect the pipe’s performance and longevity. In addition to temperature, HDPE pipes are resistant to a variety of chemicals, making them ideal for transmitting potable water as they do not leach harmful substances. Manufacturers should provide information regarding the chemical resistance of their pipes to ensure suitability for specific water quality requirements.

5. Joining Methods

One of the significant advantages of HDPE pipes is their ability to be joined using various methods. This includes heat fusion, electrofusion, and mechanical fittings. Each method has its benefits; heat fusion, for instance, provides a seamless joint that enhances the overall strength of the pipeline system. When selecting a manufacturer, it is crucial to confirm that they provide guidance and support for the joining methods suited to their products.

6. Quality Assurance and Certifications

When choosing an HDPE pipe manufacturer, it's vital to consider their quality assurance processes and certifications. Manufacturers should comply with international quality standards and possess relevant certifications (like ISO 9001) that validate their commitment to quality. Additionally, products should be tested for performance metrics, including impact resistance, tensile strength, and aging properties, to ensure they meet the required specifications for water supply.

7. Conclusion

High-Density Polyethylene pipes are essential for modern water supply systems, offering a combination of strength, flexibility, and resistance to corrosion and chemicals. When selecting HDPE pipes, it is important to consider factors such as material composition, pressure rating, temperature resistance, joining methods, and manufacturer qualifications. By understanding these specifications and carefully selecting a credible manufacturer, you can ensure that your water supply systems remain efficient, safe, and sustainable for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025