Nov . 19, 2024 06:04 Back to list

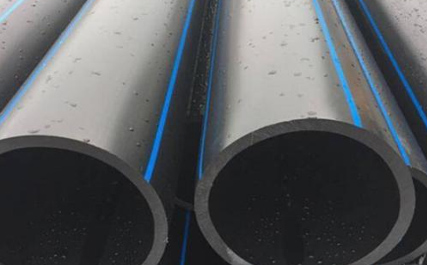

hdpe pipe for sewer line manufacturer

Understanding HDPE Pipe for Sewer Line Manufacturing

High-Density Polyethylene (HDPE) pipe has emerged as a preferred choice for sewer line applications due to its remarkable properties and benefits. The utilization of HDPE in sewer line systems has been steadily increasing, driven by its durability, versatility, and cost-effectiveness. This article delves into the significance of HDPE pipes in sewer line manufacturing, highlighting their advantages, applications, and the evolution of manufacturing processes.

What is HDPE?

HDPE, or High-Density Polyethylene, is a thermoplastic polymer made from petroleum. It is characterized by its high strength-to-density ratio, making it suitable for various applications, particularly in the construction and plumbing industries. When it comes to sewer lines, HDPE pipes offer unparalleled resistance to corrosion and chemicals, which is crucial for handling wastewater.

Advantages of HDPE Pipes

1. Durability HDPE pipes are known for their longevity, with a lifespan of 50 years or more. They are resistant to many chemicals found in wastewater, ensuring that they remain functional and reliable over time.

2. Flexibility Unlike traditional materials like concrete or PVC, HDPE pipes are flexible, allowing for easier installation in various terrains. This flexibility means they can withstand ground movements and settle without cracking or breaking.

3. Leak Resistance The joints in HDPE pipes are heat-fused, creating a single, continuous pipe system that's virtually leak-proof. This minimizes the risk of wastewater leaks, which can lead to environmental contamination and costly repairs.

5. Lightweight HDPE pipes are significantly lighter than rigid pipes, which simplifies transportation and installation. Less heavy equipment is required, reducing labor costs and installation time.

hdpe pipe for sewer line manufacturer

EHPE Pipe Manufacturing Process

The manufacturing of HDPE pipes involves several key processes. The primary methods include extrusion and molding.

1. Extrusion In this common method, plastic pellets are melted and formed into continuous pipe shapes. Extrusion allows for uniform thickness and seamless pipes, crucial for maintaining structural integrity.

2. Molding For specific applications, HDPE can also be molded into various shapes and fittings, allowing manufacturers to produce custom solutions for unique sewer line requirements.

The quality of HDPE pipes heavily depends on the availability of high-quality raw materials and adherence to manufacturing standards. Reputable manufacturers conduct rigorous testing to ensure that their products meet industry regulations, such as those set by the American Water Works Association (AWWA) and the American Society for Testing and Materials (ASTM).

Applications in Sewer Line Systems

HDPE pipes are utilized in various sewer applications, including

- Sanitary Sewer Drainage Ideal for transporting wastewater from residential and commercial properties to treatment facilities. - Stormwater Management Resilient against environmental factors, making them suitable for stormwater drainage systems. - Underground Conduits Used to protect cables and other utilities in sewer lines, preventing damage and enhancing longevity.

Conclusion

The use of HDPE pipes in sewer line manufacturing is an effective solution to the challenges posed by traditional materials. Their durability, flexibility, leak resistance, cost-effectiveness, and lightweight nature make them an ideal choice for modern sewer systems. As urbanization continues to grow and the demand for reliable infrastructure increases, HDPE pipes will play a crucial role in sustainable development and environmental protection. Manufacturers focusing on HDPE technology can expect a bright future, contributing to innovation in sewer line solutions that meet the evolving needs of communities worldwide. As the industry progresses, continuous improvements in manufacturing processes and materials will only enhance the advantages offered by HDPE pipes, solidifying their spot as a leading solution for sewer line applications.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025