Dec . 30, 2024 11:33 Back to list

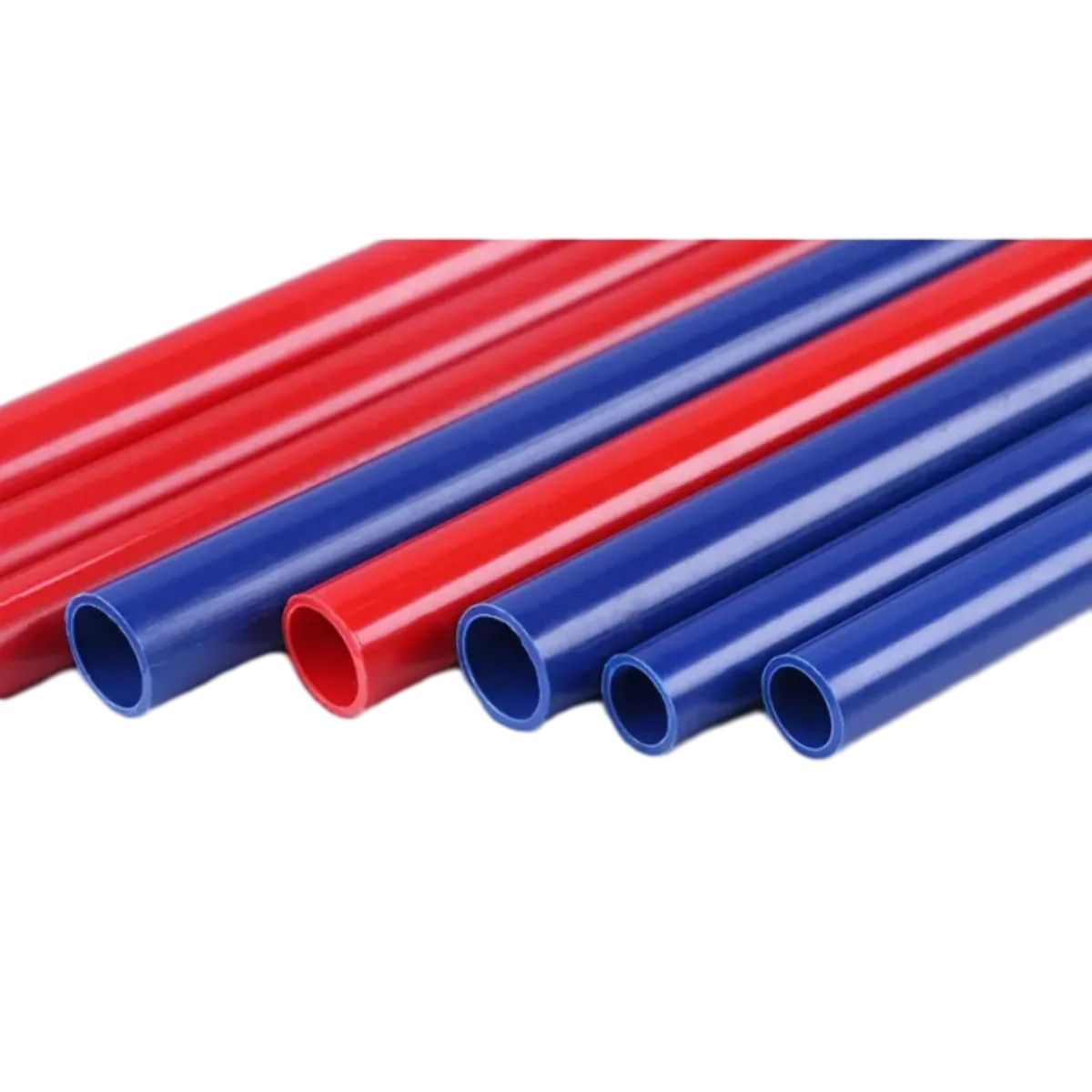

hdpe pipe for potable water products

HDPE Pipe for Potable Water Unmatched Durability and Efficiency

In the world of water distribution, the choice of materials plays a crucial role in ensuring the quality, safety, and reliability of potable water. High-Density Polyethylene (HDPE) pipe has emerged as a leading solution for potable water systems due to its unique properties and benefits. This article aims to explore the various advantages of using HDPE pipes in potable water applications, their installation process, and the essential safety standards associated with them.

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer made from petroleum. It is characterized by its high strength-to-density ratio, which makes it a sturdy and flexible material. Due to its properties, HDPE can be used in various applications, but its use in potable water systems stands out for several reasons.

Advantages of HDPE Pipes

1. Corrosion Resistance One of the primary advantages of HDPE pipes is their excellent resistance to corrosion, unlike traditional materials such as iron or copper. This property ensures that the pipes do not degrade over time, which can lead to contamination of potable water.

2. Low Leaching Potential HDPE is a non-toxic material that does not leach harmful chemicals into the water supply. This characteristic is vital for ensuring that the potable water remains safe and free from contaminants, adhering to health regulations and standards.

3. Lightweight and Easy to Handle Compared to metal pipes, HDPE pipes are significantly lighter, making transportation and installation much more manageable. This reduces labor costs and simplifies the overall process of setting up water distribution systems.

4. Flexibility and Ease of Installation HDPE pipes are highly flexible, allowing them to bend around obstacles without the need for additional fittings. This flexibility not only simplifies installation but also reduces the risk of pipe breaks or leaks caused by ground movement.

5. Longevity and Durability With an expected lifespan of over 50 years, HDPE pipes are designed to withstand the test of time. Their resistance to environmental stressors such as UV rays, chemicals, and temperature fluctuations ensures that they maintain their integrity over the years.

6. Cost-Effectiveness Although the initial cost of HDPE pipes may be comparable to other materials, the long-term savings in maintenance and replacement costs make them a more economical choice. The durability and longevity of HDPE often result in lower overall lifecycle costs.

Installation Process

hdpe pipe for potable water products

The installation of HDPE pipes usually involves several steps, ensuring reliable and efficient water distribution

1. Site Assessment Before installation, a thorough assessment of the site is conducted to determine the best layout and depth for the pipe system.

2. Trenching A trench is excavated according to the specifications for the pipe diameter and depth. The trench must be wide enough to accommodate the pipes while allowing for a stable installation.

3. Jointing Techniques HDPE pipes can be joined using various techniques such as butt fusion, electrofusion, or mechanical fittings. Each method provides a strong and leak-free connection that is essential for potable water systems.

4. Backfilling Once the pipes are installed, the trench is backfilled carefully to protect the pipes from damage. The backfill material should be free from sharp objects that could puncture the pipes.

5. Quality Testing After installation, the entire system is tested to ensure there are no leaks, and the water quality meets safety standards before it is put into operation.

Safety Standards and Regulations

Using HDPE pipes for potable water is governed by various safety standards and regulations established by organizations such as the American Water Works Association (AWWA) and the National Sanitation Foundation (NSF). These regulations ensure that materials used in drinking water applications are safe, non-toxic, and effective for long-term use.

Manufacturers of HDPE pipes for potable water must comply with these standards, providing documentation and certifications to guarantee that the materials are suitable for use in water supply systems.

Conclusion

In conclusion, HDPE pipes offer numerous advantages for potable water distribution systems including corrosion resistance, low leaching potential, flexibility, and significant cost-effectiveness over time. As municipal and private water supply systems continue to seek reliable and durable solutions, HDPE pipes stand out as a valuable investment for ensuring clean and safe drinking water for communities. With proper installation and adherence to safety standards, HDPE remains the preferred choice for modern water distribution.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025