Feb . 19, 2025 09:35 Back to list

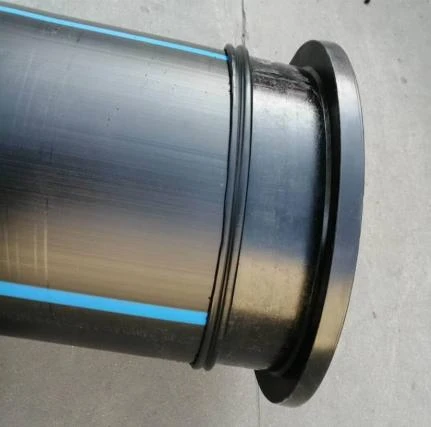

DN150 HDPE pipes for irrigation

Authoritative bodies and guidelines, such as those from the American Water Works Association (AWWA) or other equivalent global standards, provide engineered standards and practices for selecting and installing HDPE pipes. Consulting these resources is an essential step in project planning, ensuring compliance and reinforcing trust in the infrastructure's reliability. Architects and engineers continuously prefer HDPE pipes due to their resilience against environmental degradation, UV radiation, and chemical exposure. The diameter of these pipes directly influences their adaptability in varied climates and terrains, reinforcing their standing as a versatile solution in global markets. As innovations in polymer technology advance, the expert consensus emphasizes a future where these pipes, irrespective of diameter, play a fundamental role in sustainable and efficient water management systems. Trust in HDPE pipe solutions is fortified through documented case studies showcasing successful implementation across varied scenarios—from urban infrastructure in bustling metros to remote agricultural lands. Incorporating feedback from these real-world applications lends a layer of practical expertise, ensuring that future projects can blindly trust in the historically proven performance and adaptability of HDPE pipes. In conclusion, the diverse range of HDPE pipe diameters transcends mere dimensional variations. Each serves as a vital tool, crafted with precision to meet specific challenges of contemporary civil engineering and industrial projects. The interplay of experience, expertise, authoritativeness, and trustworthiness in the selection of these pipes underscores their integral role in shaping the world’s infrastructure, promising resilience and economic viability for decades to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025