Nov . 07, 2024 04:12 Back to list

hdpe pipe diameters factory

Understanding HDPE Pipe Diameters in Manufacturing

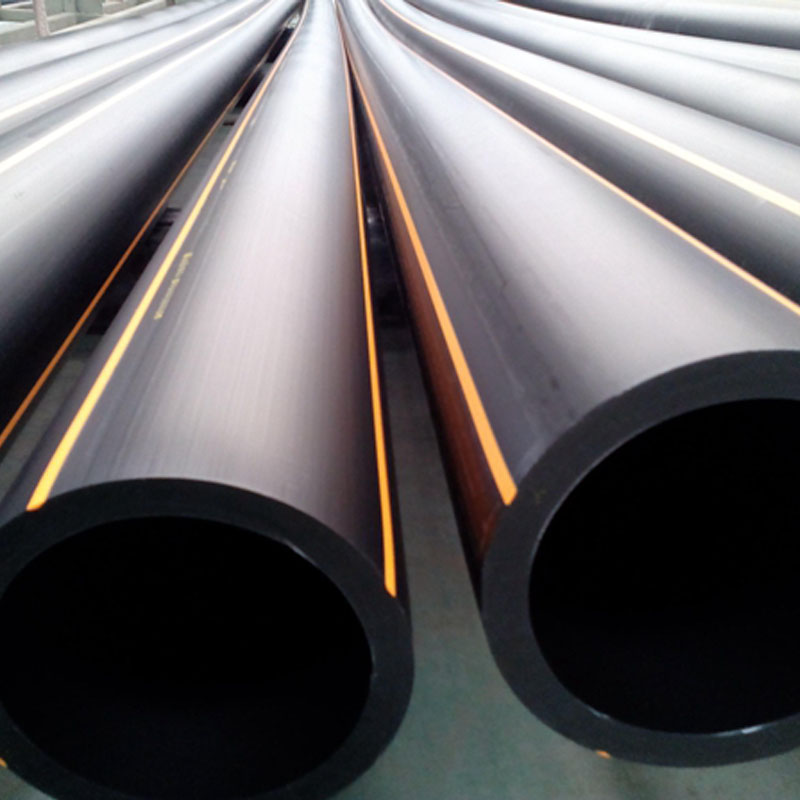

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, flexibility, and resistance to a range of environmental conditions. They are used across various industries, including water supply, gas distribution, and sewage systems. One crucial aspect of HDPE pipes is their diameter, which plays a significant role in determining the overall effectiveness and efficiency of a piping system. In this article, we will explore the significance of HDPE pipe diameters and how they influence manufacturing processes and applications.

The Importance of Pipe Diameter

The diameter of an HDPE pipe is vital because it directly affects the flow rate and pressure of the fluids transported through the system. A larger diameter allows for higher flow rates, making it suitable for applications that require transporting significant volumes of fluids. Conversely, smaller diameters may be sufficient for less demanding applications. Therefore, selecting the appropriate diameter is essential to ensure the piping system operates efficiently and effectively.

Standard Pipe Sizes

HDPE pipes are produced in a range of diameters to accommodate various needs. The American Society for Testing and Materials (ASTM) provides standard sizes, which are commonly referred to as nominal pipe sizes (NPS). These standard sizes typically range from 1 inch to 63 inches in diameter. The most commonly used sizes for residential and commercial applications include 2-inch, 4-inch, and 6-inch pipes. For larger-scale applications, such as municipal water supply systems, diameters can extend to several feet.

Manufacturing Process Considerations

hdpe pipe diameters factory

When manufacturing HDPE pipes, factors such as diameter influence the production process. The extrusion process, which is commonly used for HDPE pipe manufacturing, involves melting plastic pellets and forming them into continuous lengths of pipe. The diameter of the pipe affects the die design, cooling rates, and production speeds. For instance, larger diameters may require specialized machinery to ensure uniformity and minimize defects during production.

Additionally, different diameters may necessitate varying levels of raw material. As the diameter increases, so does the volume of HDPE material required, which can impact material costs and resource allocation. Manufacturers must carefully evaluate their production capabilities and consider inventory management for pipes of various sizes.

Applications Based on Pipe Diameter

The choice of diameter is often guided by the specific application of the HDPE pipe. For example, agricultural irrigation systems typically utilize smaller diameters, while municipal water supply lines may require larger diameters to accommodate higher flow rates. In the energy sector, HDPE pipes are employed in gas distribution, where the diameter must be carefully matched to operational pressures and flow requirements.

Conclusion

In conclusion, the diameter of HDPE pipes is a critical factor in their design, manufacturing, and application. Understanding the nuances of pipe diameters can help manufacturers produce high-quality products that meet industry standards and customer needs. As industries continue to evolve, the demand for efficient and effective piping solutions will remain essential, making the study of HDPE pipe diameters increasingly relevant in manufacturing discussions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025