Feb . 19, 2025 07:56 Back to list

hdpe sprinkler pipe manufacturers

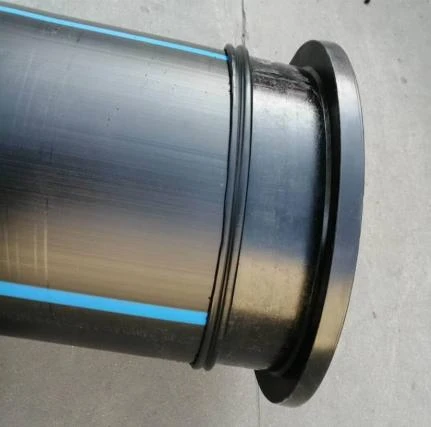

A notable attribute of HDPE pipes, regardless of diameter, is their ability to resist corrosion and chemical interactions. This characteristic enhances their durability and extends operational life, solidifying the trustworthiness of HDPE pipes in long-term infrastructure projects. Additionally, HDPE pipes are lightweight, contributing to reduced transportation costs and easier handling during installation. Innumerable testimonials from industry experts underscore the reliability and efficiency of HDPE pipes. For instance, engineers in water management projects frequently commend HDPE pipes for their hassle-free installation and minimal maintenance requirements. Similarly, gas distribution professionals highlight their negligible leakage rates, attributing this to the pipes' seamless and flexible construction that accommodates ground movements without cracking. Nonetheless, the production of HDPE pipes demands stringent adherence to quality standards. Reputable factories are equipped with advanced technologies for precise measurements and quality assurance testing. These facilities follow internationally recognized standards, such as ISO 4427 for water supply systems, ensuring that every piece of pipe not only meets but exceeds performance expectations. In conclusion, HDPE pipe diameters play a pivotal role in various applications, with each size serving a unique purpose that addresses specific operational needs. Factories involved in the production of HDPE pipes employ cutting-edge technology and possess a wealth of experience to deliver products that stand as a testament to high-quality engineering and reliability. As the demand for sustainable and durable piping solutions continues to evolve, manufacturers remain committed to advancing their practices, ensuring the delivery of trusted HDPE products tailored to meet the diverse requirements of modern infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025