Oct . 20, 2024 06:53 Back to list

hdpe pipe diameters factories

Understanding HDPE Pipe Diameters and their Manufacturing

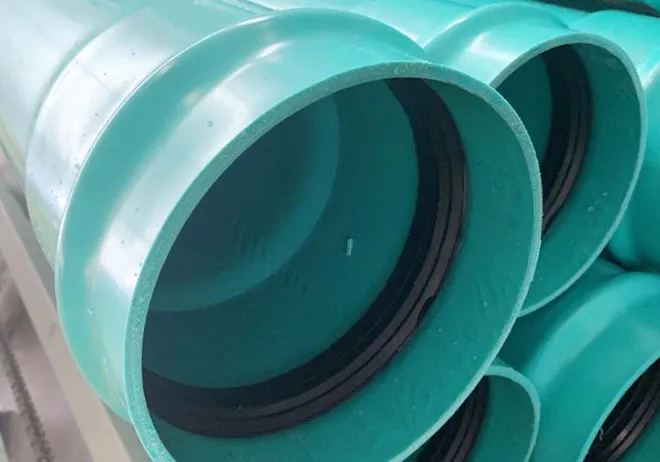

High-Density Polyethylene (HDPE) pipes have become a staple in various industries due to their versatility, durability, and resistance to corrosion. As the demand for efficient water transportation and sewage disposal systems grows, understanding the specifications and manufacturing processes of HDPE pipes, particularly their diameters, becomes essential for engineers and contractors alike.

Importance of HDPE Pipe Diameters

HDPE pipes come in a variety of diameters to accommodate different applications. The diameters range from small sizes that are suitable for residential plumbing systems to larger pipes used in municipal water supply networks, industrial applications, and agricultural systems. The selection of the right diameter is critical as it influences flow rates, pressure, and overall system efficiency.

1. Flow Rate and Pressure The diameter of the pipe directly affects the velocity of the fluid flowing through it. Smaller diameters can cause an increase in fluid velocity, potentially leading to higher pressure drops and inefficiencies. Conversely, larger diameters support higher flow rates with lower friction losses. As a general rule, engineers must strike a balance between the diameter and the specific requirements of the project.

2. Application Suitability Different applications have different requirements. For instance, a residential water supply might utilize pipes with diameters ranging from 20mm to 50mm, while agricultural irrigation can require larger diameters, often exceeding 100mm. In municipal applications, HDPE pipes can be found with diameters ranging from 110mm to 400mm or even larger.

Manufacturing Process

hdpe pipe diameters factories

The manufacturing of HDPE pipes involves several stages, each playing a crucial role in determining the pipe’s quality and diameter accuracy. The process typically includes extrusion, cooling, and testing.

1. Extrusion The primary manufacturing method for HDPE pipes is extrusion. In this process, plastic pellets made of high-density polyethylene are fed into an extruder where they are heated until they melt. The molten HDPE is then pushed through a die that shapes it into a pipe of the desired diameter and thickness. This is a continuous process that allows for precise control over the pipe dimensions.

2. Cooling Once the HDPE pipe exits the extruder, it enters a cooling chamber where it is cooled to solidify the material. The cooling process is critical as it helps maintain the pipe's diameter and ensures it adheres to industry standards. Typically, water or air cooling methods are used, depending on the factory's setup.

3. Testing and Quality Control After cooling, the pipes are subjected to various quality tests to ensure they meet specific standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). Tests include checking for dimensional accuracy, pressure testing, and inspecting for any material defects. Manufacturers often use advanced technology like ultrasonic testing and hydrostatic testing to assess the strength and integrity of the pipes.

Conclusion

In conclusion, HDPE pipe diameters are not merely numbers; they represent critical factors that impact the efficiency and functionality of fluid transport systems. Understanding the relationship between pipe diameter and application requirements is crucial for optimal design and installation. Furthermore, advancements in manufacturing processes have allowed factories to produce high-quality HDPE pipes consistently. As industries continue to evolve, the need for reliable water supply and drainage solutions will ensure that HDPE pipes remain a fundamental component of modern infrastructure. By selecting the appropriate HDPE pipe diameter, engineers and contractors can contribute to more sustainable and efficient systems worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025