Feb . 19, 2025 08:46 Back to list

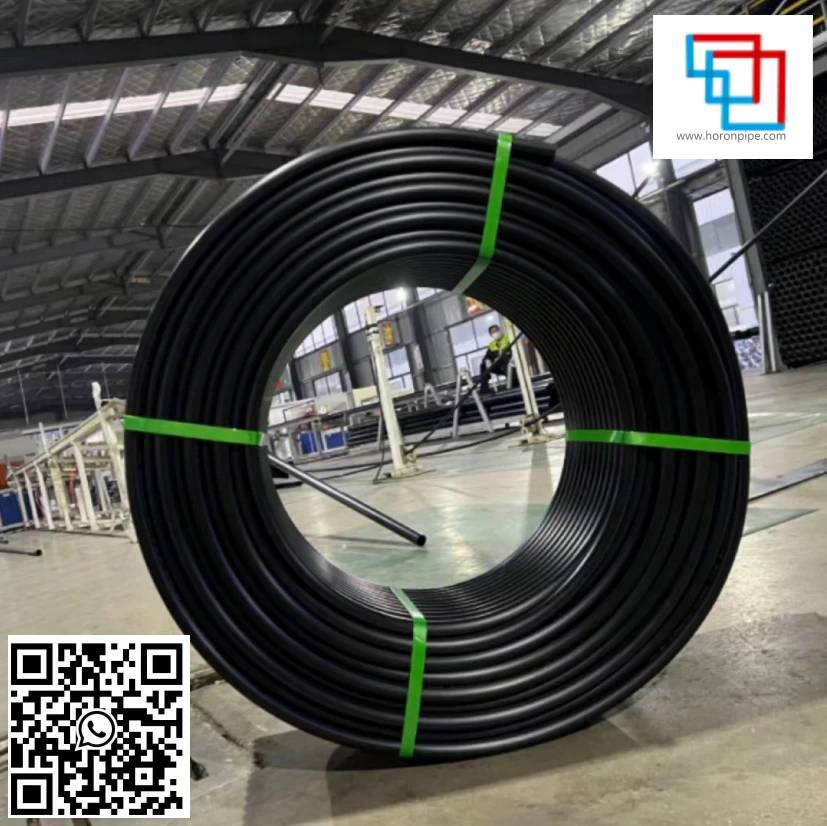

DN150 HDPE pipes for irrigation

One authoritative approach within the industry is the adherence to bimodal polyethylene technology, which grants enhanced mechanical properties to HDPE pipes, particularly in larger diameters. This bimodal approach achieves a substantial balance between rigidity for maintaining diameter and flexibility for installation dynamics, especially in environments subjected to fluctuating temperatures. Users in industrial applications often demand pipes that can withstand high pressures and resist environmental stress cracking, and factories with this capability receive a high level of trust from global clients. From an expert perspective, it’s essential to grasp the customization potential available in HDPE pipe manufacturing. Factories that provide tailored diameter solutions enhance their service spectrum, allowing clients to procure custom pipes that exactly match their project requirements. This ability to customize diameters to fine-tuned specifications not only ensures operational efficiency but also positions the factory as a leader in innovation and client satisfaction. Trustworthiness in the HDPE manufacturing sector is reinforced through transparent operations and certifications. Factories with ISO certifications or similar standards demonstrate a commitment to quality and consistency, propelling them as trusted suppliers in international markets. This is complemented by reviews and case studies from previous projects, which reveal real-world performance data of their diameter-specific HDPE pipes. In summary, the niche world of HDPE pipe diameters is a testament to industrial precision, cutting-edge technology, and the adaptability of manufacturing processes. Factories at the forefront of this industry exhibit a harmonious blend of expertise, experience, authoritativeness, and trustworthiness. These attributes enable them to produce superior HDPE pipes that stand up to varied demands—whether that's enduring harsh climatic conditions or upholding infrastructure integrity for decades. When selecting an HDPE pipe supplier, one must consider these factors intricately tied to diameter reliability to ensure optimal project outcomes.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025