Nov . 18, 2024 22:07 Back to list

HDPE Pipe Couplings for Reliable Connections in Water and Wastewater Applications

Understanding HDPE Pipe Couplings A Comprehensive Overview

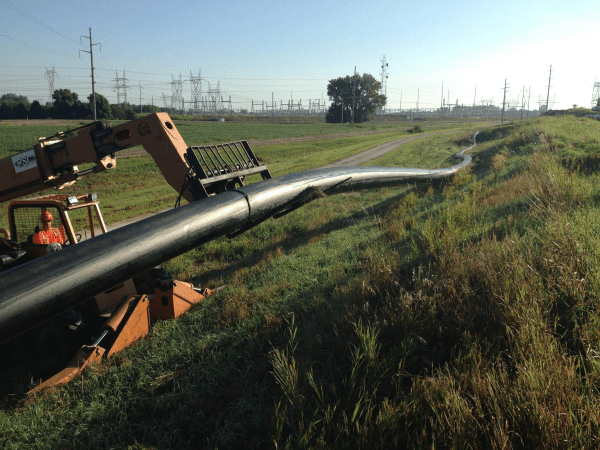

High-Density Polyethylene (HDPE) pipe couplings are crucial components in the construction and maintenance of various piping systems. Known for their durability and flexibility, HDPE pipes are widely used in water supply, sewage systems, and industrial applications. This article will delve into the significance of HDPE pipe couplings, their types, applications, and advantages.

What Are HDPE Pipe Couplings?

HDPE pipe couplings are fittings that connect two sections of HDPE piping. These couplings allow for the seamless transmission of fluids and gases while accommodating the thermal expansion and contraction of the pipes. They are available in various sizes, designs, and materials, but they all serve the fundamental purpose of creating a secure joint between pipe segments.

Types of HDPE Couplings

There are several types of HDPE couplings designed to cater to specific requirements

1. Mechanical Couplings These couplings use bolts and clamps to connect two pipes. They are quick to install and can be easily adjusted or removed, which makes them perfect for maintenance needs.

2. Electrofusion Couplings These utilize electrical heat to melt the edges of the pipes and the coupling, creating a strong bond as the material cools. This method is highly reliable for underground applications.

3. Butt Fusion Couplings This type involves heating the ends of two pipes and then pressing them together until they meld. Butt fusion provides a permanent and robust joint.

hdpe pipe couplings products

4. Flanged Couplings Used when frequent disassembly is required, flanged couplings allow for easy connection and disconnection of pipe segments.

Applications of HDPE Pipe Couplings

HDPE pipe couplings are versatile and find use in various industries, including

- Water Supply Systems Ensuring the reliable conveyance of drinking water. - Sewage Management Managing wastewater effectively. - Irrigation Systems Providing efficient water distribution in agriculture. - Industrial Applications Transporting chemicals and other substances safely.

Advantages of Using HDPE Pipe Couplings

The benefits of HDPE pipe couplings are numerous

- Durability HDPE material is resistant to corrosion and chemicals, allowing for long-lasting use. - Flexibility HDPE pipes can bend without breaking, accommodating shifts in the ground or other environmental changes. - Ease of Installation Many types of couplings can be installed quickly, reducing labor time and costs. - Cost-Effectiveness The longevity and minimal maintenance needs of HDPE systems translate to lower overall costs.

In conclusion, HDPE pipe couplings play a vital role in the integrity and efficiency of piping systems. Their diverse types and applications, coupled with numerous advantages, make them an excellent choice for various industries. As infrastructure continues to evolve, the importance of high-quality, reliable coupling solutions will only increase.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025